Abstract

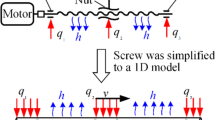

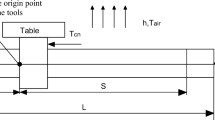

The thermal error of the ball screw feed system will reduce the positioning accuracy of the machine tool, and the main reason for the thermal error is the friction heat generated by bearings and screw nut in the feed system. Therefore, a time-varying thermal error prediction method of the ball screw feed system based on the inverse method is proposed in this paper. Based on data-driven and dynamic thermal network model, the heat source estimation method of ball screw feed system under unsteady thermal effect is established, and the thermodynamic equilibrium equation is deduced into explicit form for heat source load identification. Aiming at the common matrix ill-conditioned problem of load identification, the regularization algorithm is used to identify the heat source load, and the optimal selection method of regularization parameters is proposed based on Monte Carlo algorithm. Using the collected temperature experiment data and the position data of the moving nut, the dynamic heat source load, temperature field, and thermal error of the feed system under the actual working condition are predicted and analyzed by using the inverse method. Finally, the accuracy and effectiveness of the prediction method are verified by experiment. The inverse method proposed in this paper has great application potential for the prediction and estimation of heat source and temperature field of machine tools and various mechanical structures.

Similar content being viewed by others

Availability of data and material

The data cannot be shared openly, to protect study participant privacy.

Code availability

The code cannot be shared openly, to protect study participant privacy.

References

Mayr J, Jedrzejewski J, Uhlmann E (2012) Thermal issues in machine tools. CIRP Ann Manuf Technol 61(2):771–791

Altintas Y, Verl A, Brecher C et al (2011) Machine tool feed drives. CIRP Ann Manuf Technol 60(2):779–796

Bryan J (1990) International status of thermal error research. CIRP Ann - Manuf Technol 39(2):645–656

Liu K, Sun M, Zhu T et al (2016) Modeling and compensation for spindle's radial thermal drift error on a vertical machining center. Int J Mach Tools Manuf 58–67

Uhlmann E, Marcks P (2008) Compensation of thermal deformations at machine tools using adaptronic CRP-Structures. Springer, London

Xu ZZ, Liu XJ, Kim HK et al (2011) Thermal error forecast and performance evaluation for an air-cooling ball screw system. Int J Mach Tools Manuf 51(7–8):605–611

Yang AS, Cai SZ, Hsieh SH et al (2013) Thermal deformation estimation for a hollow ball screw feed drive system. Lect Notes Comput Sci

Zhang JF, Feng PF, Wu ZJ et al (2013) Thermal structure design and analysis of a machine tool headstock. Mechanika 19(4):478–485

Miao E, Yan Y, Fei Y (2011) Application of time series to thermal error compensation of machine tools. Proc SPIE-Int Soc Opt Eng 7997(2):261–274

Yang J, Zhang D, Feng B et al (2014) Thermal-induced errors prediction and compensation for a coordinate boring machine based on time series analysis. Math Probl Eng 2:1–13

Abdulshahed AM, Longstaff AP, Fletcher S (2017) A cuckoo search optimisation-based grey prediction model for thermal error compensation on CNC machine tools. Grey systems: theory and application 7(2):146–155

Rojek I, Kowal M, Stoic A (2017) Predictive compensation of thermal deformations of ball screws in CNC machines using neural networks. Tehnicki Vjesnik 24(6):1697–1703

Gao X, Guo Y, Hanson DA et al (2021) Thermal error prediction of ball screws based on PSO-LSTM. Int J Adv Manuf Technol 116(5–6):1721–1735

Ma C, Gui H, Liu J (2021) Self learning-empowered thermal error control method of precision machine tools based on digital twin. J Intell Manuf 1–23

Li ZJ, Zhao CY, Lu ZC (2020) Thermal error modeling method for ball screw feed system of CNC machine tools in x-axis. Int J Adv Manuf Technol 106(2):5383–5392

Wang L, Wang H, Li T, Li FC (2015) A hybrid thermal error modeling method of heavy machine tools in z-axis. Int J Adv Manuf Technol 80(1–4):389–400

Liu J, Ma C, Wang S et al (2019) Thermal boundary condition optimization of ball screw feed drive system based on response surface analysis. Mech Syst Signal Process 121:471–495

Liu K, Liu H, Li T et al (2019) Intelligentization of machine tools: comprehensive thermal error compensation of machine-workpiece system. Int J Adv Manuf Technol 102(9–12):3865–3877

Liu K, Song L, Han W et al (2022) Time-varying error prediction and compensation for movement axis of CNC machine tool based on digital twin. IEEE Trans Industr Inf 18(1):109–118

Wang G, Zhang L, Wang X et al (2016) An inverse method to reconstruct the heat flux produced by bone grinding tools. Int J Therm Sci 101:85–92

Duda P (2016) A method for transient thermal load estimation and its application to identification of aerodynamic heating on atmospheric reentry capsule. Aerosp Sci Technol 51:26–33

Liu CS, Qiu L, Lin J (2019) Solving the higher-dimensional nonlinear inverse heat source problems by the superposition of homogenization functions method. Int J Heat Mass Transf 141:651–657

Lv C, Wang G, Chen H (2020) Inverse determination of thermal boundary condition and temperature distribution of workpiece during drilling process. Measurement 171(3):108822–108836

Funding

This work was supported by the following research projects: National Natural Science Foundation of China under Grants 51775094, 51975386; The Basic Research Project of Education Department of Liaoning Province (Grant No. JJL202015401).

Author information

Authors and Affiliations

Contributions

Zhen-jun Li: conceptualization, methodology, software, writing original draft preparation (lead). Zhi Tan: supervision. Ze-chen Lu: data curation. Ye Chen: validation. Yu-chuan Fan: data curation, supervision.

Corresponding author

Ethics declarations

Ethical approval and consent to participate

Not applicable.

Consent to publish

The authors confirm that neither the entire paper nor any part of its content has been published or has been accepted elsewhere and its publication has been approved by all co-authors. The authors agree to publication in the International Journal of Advanced Manufacturing Technology.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Zj., Tan, Z., Chen, Y. et al. Thermal error prediction of ball screw feed system based on inverse heat transfer analysis. Int J Adv Manuf Technol 122, 2607–2624 (2022). https://doi.org/10.1007/s00170-022-10076-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10076-8