Abstract

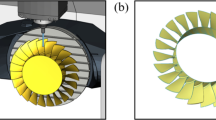

Blade is the core component of aero-engine, and its manufacturing capability improvement has always been the focus of aviation manufacturing industry. With the high-efficiency machining of multi-spindle machine tool, this paper proposes a synchronous polishing method based on the cluster grouping of actual blade profile. Firstly, the multi-spindle machining system, flexible polishing with determined path, and synchronous polishing process cycle are analyzed in detail. Secondly, the allowable difference within group is determined by the relationship of polishing compression and surface roughness/removal. Then, the distribution of grouping mark points is determined by the profile differences of sampled blades. Thirdly, the consistency of each two blade profiles is expressed as the vector difference of measurement data, and the grouping result can be established with the Ray-Turi index. Finally, a typical blade is used to demonstrate the effectiveness and efficiency. After multi-spindle synchronous polishing, the average synchronous polishing cycle time is 3.14 times less than single-spindle machine tool, the profile error and its difference are less than 0.0685 mm and 0.048 mm, the surface roughness can satisfy \({Ra}\le 0.4 {\mu m}\), which can meet the design requirement of aero-engine blade.

Similar content being viewed by others

Availability of data and materials

Not applicable.

Code availability

Not applicable.

References

Wang H, Zhu D, Liu J (2019) Improving the accuracy of the blade leading/trailing edges by electrochemical machining with tangential feeding. CIRP Ann 68(1):165–168

Lv YJ, Peng Z, Qu C, Zhu D (2020) An adaptive trajectory planning algorithm for robotic belt grinding of blade leading and trailing edges based on material removal profile model. Robot Comput-Integr Manuf 66:101987

Chong ZH, Xie FG, Li XJ, Wang JS, Niu HF (2020) Design of the parallel mechanism for a hybrid mobile robot in wind turbine blades polishing. Robot Comput-Integr Manuf 61(4):101857

Flexmill (2022) Turbine Blade Finishing [OL]. https://www.flexmill.fi/applications/turbine-blade-finishing/

Zhou P, Zhao X, Tao B, Ding H (2020) Time-varying isobaric surface reconstruction and path planning for robotic grinding of weak-stiffness workpieces. Robot Comput-Integr Manuf 64(8)101945

Liu D, Shi Y, Lin X, Xian C (2019) Study on improving surface residual stress of polished blade after polishing based on two-stage parameter method. Int J Adv Manuf Technol 100(7)

Zhi H, Yun H, Zhang W, Wu YY (2009) The development of cutter location algorithm for the 6axis simultaneous CNC abrasive belt grinding complex surface. Key Eng Mater 416:375–380

Xiao GJ, Huang Y (2016) Equivalent self-adaptive belt grinding for the real-R edge of an aero-engine precision-forged blade. Int J Adv Manuf Technol 83(9–12):1697–1706

Xiao GJ, Huang Y, Yin J (2017) An integrated polishing method for compressor blade surfaces. Int J Adv Manuf Technol 88(5–8):1723–1733

He Q, Zhao J, Feng M, Zhang CP, Chen HD (2019) A study on the control strategies of a series–parallel hybrid platform for blade polishing. Int J Adv Manuf Technol 102(1–4):265–275

Wu D, Wang H, Zhang K, Lin XJ (2019) Research on flexible adaptive CNC polishing process and residual stress of blisk blade. Int J Adv Manuf Technol 103:2495–2513

Chen Z, Shi Y, Lin X, Zhang JF, Kang C, Shan XF, Zhang N, Zhao P, He XD, Li HL (2019) A profile-adaptive compliant polishing tool for aero-engine blade finishing process. Int J Adv Manuf Technol 102:3825–3838

Xu XH, Chen W, Zhu DH, Yan S, Ding S (2021) Hybrid active/passive force control strategy for grinding marks suppression and profile accuracy enhancement in robotic belt grinding of turbine blade. Robot Comput-Integr Manuf 67:102047

Zhu DH, Feng XZ, Xu XH, Yang Z, Ding H (2020) Robotic grinding of complex components: a step towards efficient and intelligent machining challenges, solutions, and applications. Robot Comput-Integr Manuf 6:101908

Xu XH, Zhu DH, Wang JS, Ding H (2018) Calibration and accuracy analysis of robotic belt grinding system using the ruby probe and criteria sphere. Robot Comput-Integr Manuf 51:189–201

Xu XH, Zhu DH, Zhang HY, Ding H (2019) Application of novel force control strategies to enhance robotic abrasive belt grinding quality of aero-engine blades. Chin J Aeronaut 32(10):2368–2382

Ye H, Chen ZT, Xie ZQ, Li SB, Su S (2021) A material removal model for nonconstant-contact flexible grinding. Int J Adv Manuf Technol. https://doi.org/10.21203/rs.3.rs-741799/v1

Quan F, Chen Z, Li Q, Gao SM (2019) Effects of process combinations of milling, grinding, and polishing on the surface integrity and fatigue life of GH4169 components. Proc Inst Mech Eng Part B J Eng Manuf 234(3):095440541986805

STAMA (2022) System 5 Two Place [OL]. https://stama.de/1/overview-machining-centers/system-5-two-place/

Wu D, Wang H, Yu J (2021) Machining errors control method for near-net-shape jet engine blade CNC machining process. J Phys Conf Ser 1885(2):022006

Zhang Y, Chen ZT, Wang X (2020) A sampling method for blade measurement based on statistical analysis of profile deviations. Measurement 163(1):107949

Jiang RS, Wang WH, Zhang DH, Wang ZQ (2016) A practical sampling method for profile measurement of complex blades. Measurement 81:57–65

Wang XD, Zhang Y (2021) Research on blade grouping method for array machining. Proc Inst Mech Eng Part B J Eng Manuf 235(9):1437–1446

Funding

This work was supported by the National Defense Basic Scientific Research program of China (JCKY202120bB507), R&D Program of Beijing Municipal Education Commission and the Aeronautical Science Foundation of China (20200016112001).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by Zhuang Yun, Chen Zhitong, and Wang Xiaodong. The first draft of the manuscript was written by Zhang Yun and Zhu Zhengqing. All authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yun, Z., Wang, X., Chen, Z. et al. A synchronous polishing method for aero-engine blade based on multi-spindle machine tool. Int J Adv Manuf Technol 123, 1669–1678 (2022). https://doi.org/10.1007/s00170-022-10025-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10025-5