Abstract

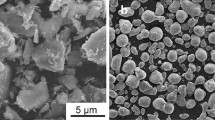

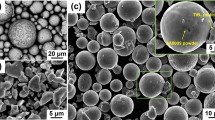

As one of the important additive manufacturing techniques, selective laser melting (SLM) has shown great advantage in the production of metal matrix composite components with complex geometry. However, the layer-by-layer manufacturing procedure causes a nonnegligible thermal accumulation and cycling. Thus, the SLM-deposited component always presents gradient microstructure and mechanical properties. In this work, the dense TiB2p/2024Al composite prepared by SLM was employed to investigate the heat-induced microstructure evolution and mechanical properties. The as-deposited composite presents a uniform distribution of TiB2 reinforced particle in α-Al matrix with an oriented < 100 > texture α-Al dendrite microstructure. The yield strength (YS), ultimate tensile strength (UTS), and the elongation of as-deposited sample increase from 230.06 MPa, 302.52 MPa, and 4.49% to 244.17 MPa, 365.36 MPa, and 11.48% from the bottom to top regions. According to the TEM results, this phenomenon is attributed to the high cooling rate induced low content of θ-Al2Cu phase at the bottom of the sample. In addition, agglomeration of the TiB2 particles due to the insufficient convention is responsible to the poor elongation at the bottom of the sample. After the solid solution and aging heat treatment (T6), thanks to the uniform distribution of S strengthening phases, this gradient in microstructure and mechanical properties in the deposit can be eliminated, and the deposit presents higher YS, UTS, and a lower elongation of 380.23 MPa, 421.50 MPa, and 3.14%.

Similar content being viewed by others

References

Kang N, Lin X, Mansori ME, Wang QZ, Lu JL, Coddet C, Huang WD (2020) On the effect of the thermal cycle during the directed energy deposition application to the in-situ production of a Ti-Mo alloy functionally graded structure. Addit Manuf 31:100911. https://doi.org/10.1016/j.addma.2019.100911

Zhang H, Zhu H, Qi T, Hu Z, Zeng X (2016) Selective laser melting of high strength Al–Cu–Mg alloys: processing, microstructure and mechanical properties. Mater Sci Eng A 656:47–54. https://doi.org/10.1016/j.msea.2015.12.101

Wang P, Gammer C, Brenne F, Prashanth KG, Mendes RG, Rümmeli MH, Gemming T, Eckert J, Scudino S (2018) Microstructure and mechanical properties of a heat-treatable Al-3.5Cu-1.5Mg-1Si alloy produced by selective laser melting. Mater Sci Eng A 711:562–570. https://doi.org/10.1016/j.msea.2017.11.063

Thijs L, Kempen K, Kruth J-P, Van Humbeeck J (2013) Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater 61:1809–1819. https://doi.org/10.1016/j.actamat.2012.11.052

Nie X, Zhang H, Zhu H, Hu Z, Ke L, Zeng X (2018) Analysis of processing parameters and characteristics of selective laser melted high strength Al-Cu-Mg alloys: from single tracks to cubic samples. J Mater Process Technol 256:69–77. https://doi.org/10.1016/j.jmatprotec.2018.01.030

Gu D, Jue J, Dai D, Lin K, Chen W (2018) Effects of dry sliding conditions on wear properties of al-matrix composites produced by selective laser melting additive manufacturing. J Tribol 140:021605. https://doi.org/10.1115/1.4037729

Lin X, Huang W (2015) High performance metal additive manufacturing technology applied in aviation field. Mater China 34:684–688

Jia Q, Gu D (2014) Selective laser melting additive manufacturing of Inconel 718 superalloy parts: densification, microstructure and properties. J Alloy Compd 585:713–721. https://doi.org/10.1016/j.jallcom.2013.09.171

DebRoy T, Wei HL, Zuback JS, Mukherjee T, Elmer JW, Milewski JO, Beese AM, Wilson-Heid A, De A, Zhang W (2018) Additive manufacturing of metallic components—process, structure and properties. Prog Mater Sci 92:112–224. https://doi.org/10.1016/j.pmatsci.2017.10.001

Xu W, Brandt M, Sun S, Elambasseril J, Liu Q, Latham K, Xia K, Qian M (2015) Additive manufacturing of strong and ductile Ti–6Al–4V by selective laser melting via in situ martensite decomposition. Acta Mater 85:74–84. https://doi.org/10.1016/j.actamat.2014.11.028

Wang X, Chou K (2017) Effects of thermal cycles on the microstructure evolution of Inconel 718 during selective laser melting process. Addit Manuf 18:1–14. https://doi.org/10.1016/j.addma.2017.08.016

Kang N, Coniglio N, Cao Y, Zhao C, El Mansori M, Zhao Y, Lin X, Coddet C (2021) Intrinsic heat treatment induced graded surficial microstructure and tribological properties of selective laser melted titanium. J Tribol 143. https://doi.org/10.1115/1.4049701

Moy CKS, Weiss M, Xia J, Sha G, Ringer SP, Ranzi G (2024) Influence of heat treatment on the microstructure, texture and formability of aluminium alloy. Mater Sci Eng A 552(2012):48–60. https://doi.org/10.1016/j.msea.2012.04.113

Wen X, Wang Q, Mu Q, Kang N, Sui S, Yang H, Lin X, Huang W (2019) Laser solid forming additive manufacturing TiB2 reinforced 2024Al composite: microstructure and mechanical properties. Mater Sci Eng A 745:319–325. https://doi.org/10.1016/j.msea.2018.12.072

Martin JH, Yahata BD, Hundley JM, Mayer JA, Schaedler TA, Pollock TM (2017) 3D printing of high-strength aluminium alloys. Nature 549:365–369. https://doi.org/10.1038/nature23894

Tan Q, Zhang J, Sun Q, Fan Z, Li G, Yin Y, Liu Y, Zhang M-X (2024) Inoculation treatment of an additively manufactured aluminium alloy with titanium nanoparticles. Acta Mater 196(2020):1–16. https://doi.org/10.1016/j.actamat.2020.06.026

Li XP, Ji G, Chen Z, Addad A, Wu Y, Wang HW, Vleugels J, Van Humbeeck J, Kruth JP (2017) Selective laser melting of nano-TiB2 decorated AlSi10Mg alloy with high fracture strength and ductility. Acta Mater 129:183–193. https://doi.org/10.1016/j.actamat.2017.02.062

Wang P, Gammer C, Brenne F, Niendorf T, Eckert J, Scudino S (2018) A heat treatable TiB2/Al-3.5 Cu-1.5 Mg-1Si composite fabricated by selective laser melting: microstructure, heat treatment and mechanical properties. Compos Part B Eng 147:162–168. https://doi.org/10.1016/j.compositesb.2018.04.026

Nie X, Zhang H, Zhu H, Hu Z, Qi Y, Zeng X (2019) On the role of Zr content into Portevin-Le Chatelier (PLC) effect of selective laser melted high strength Al-Cu-Mg-Mn alloy. Mater Lett 248:5–7. https://doi.org/10.1016/j.matlet.2019.03.112

Qi Y, Zhang H, Zhu J, Nie X, Hu Z, Zhu H, Zeng X (2020) Mechanical behavior and microstructure evolution of Al-Cu-Mg alloy produced by laser powder bed fusion: effect of heat treatment. Mater Charact 165:110364. https://doi.org/10.1016/j.matchar.2020.110364

Geng J, Hong T, Ma Y, Wang M, Chen D, Ma N, Wang H (2016) The solution treatment of in-situ sub-micron TiB2/2024Al composite. Mater Des 98:186–193. https://doi.org/10.1016/j.matdes.2016.03.024

Du R, Gao Q, Wu S, Lü S, Zhou X (2018) Influence of TiB2 particles on aging behavior of in-situ TiB2/Al-4.5Cu composites. Mater Sci Eng A 721:244–250. https://doi.org/10.1016/j.matdes.2016.03.024

Lopez-Botello O, Martinez-Hernandez U, Ramírez J, Pinna C, Mumtaz K (2017) Two-dimensional simulation of grain structure growth within selective laser melted AA-2024. Mater Des 113:369–376. https://doi.org/10.1016/j.matdes.2016.10.031

Cao Y, Lin X, Kang N, Ma L, Wei L, Zheng M, Yu J, Peng D, Huang W (2021) A novel high-efficient finite element analysis method of powder bed fusion additive manufacturing. Addit Manuf 46:102187. https://doi.org/10.1016/j.addma.2021.102187

Liu Z, Wang Z (2018) Effect of substrate preset temperature on crystal growth and microstructure formation in laser powder deposition of single-crystal superalloy. J Mater Sci Technol 34:2116–2124. https://doi.org/10.1016/j.jmst.2018.04.016

Zhang MX, Kelly PM, Easton MA, Taylor JA (2005) Crystallographic study of grain refinement in aluminum alloys using the edge-to-edge matching model. Acta Mater 53:1427–1438. https://doi.org/10.1016/j.actamat.2004.11.037

Gharbi O, Jiang D, Feenstra DR, Kairy SK, Wu Y, Hutchinson CR, Birbilis N (2018) On the corrosion of additively manufactured aluminium alloy AA2024 prepared by selective laser melting. Corros Sci 143:93–106. https://doi.org/10.1016/j.corsci.2018.08.019

Chen H, Gu D, Dai D, Ma C, Xia M (2017) Microstructure and composition homogeneity, tensile property, and underlying thermal physical mechanism of selective laser melting tool steel parts. Mater Sci Eng A 682:279–289. https://doi.org/10.1016/j.msea.2016.11.047

Zhou F, Liao XZ, Zhu YT, Dallek S, Lavernia EJ (2003) Microstructural evolution during recovery and recrystallization of a nanocrystalline Al-Mg alloy prepared by cryogenic ball milling. Acta Mater 51:2777–2791. https://doi.org/10.1016/S1359-6454(03)00083-1

Rao JH, Zhang Y, Zhang K, Huang A, Davies CHJ, Wu X (2019) Multiple precipitation pathways in an Al-7Si-0.6Mg alloy fabricated by selective laser melting. Scr Mater 160:66–69. https://doi.org/10.1016/j.scriptamat.2018.09.045

Zhang H, Zhu H, Nie X, Yin J, Hu Z, Zeng X (2017) Effect of Zirconium addition on crack, microstructure and mechanical behavior of selective laser melted Al-Cu-Mg alloy. Scr Mater 134:6–10. https://doi.org/10.1016/j.scriptamat.2017.02.036

Funding

The work was supported by the National Key R&D Program of China (Grant No. 2016YFB1100100), National Natural Science Foundation (Grant No. 52005411), the Research Fund of the State Key Laboratory of Solidification Processing (NPU), China (Grant No. 2020-TZ-02), and the China Scholarship Council (Grant No.202106290075).

Author information

Authors and Affiliations

Contributions

Qingzheng Wang: investigation, data curation, methodology, writing—original draft. Mohamed El Mansori: review and editing, supervision. Xin Lin: funding acquisition, project administration, resources, supervision validation, writing—review and editing. Yang CAO: investigation and thermal simulation. Nan Kang: writing—review and editing, supervision. Weidong Huang: funding acquisition, resources.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Q., Lin, X., Mansori, M.E. et al. From gradient to homogenous: thermal behavior-induced microstructure evolution and mechanical properties of selective laser-melted TiB2p/2024Al composite. Int J Adv Manuf Technol 122, 4341–4352 (2022). https://doi.org/10.1007/s00170-022-09882-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09882-x