Abstract

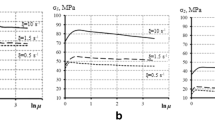

A study was made for the modes of production technology of wire from the Pd-5Ni alloy with a diameter of 0.075 mm for catchment gauzes and the influence of pressure treatment parameters on the structure and properties of the obtained deformed semi-finished products was investigated. Computer models of cold sectional rolling of workpieces and subsequent drawing of Pd-5Ni alloy wire from them have been developed. The models made it possible to evaluate the stress–strain state of the metal during its processing, to determine the force conditions of rolling and drawing, and also to predict the destruction of workpieces using the Cockcroft-Latham criterion. Testing of the simulation results was carried out on industrial equipment, consisting of a pneumatic hammer to obtain a workpiece of a square section of 30 × 30 mm, three sectional rolling mills with a rhombus-square system to obtain a workpiece of a square section of 3.45 × 3.45 mm and three drawing mills. On the first two rolling mills, the workpiece was rolled by sequential movement along the calibers, and on the third mill, rolling was carried out in a continuous mode. To obtain a wire with a diameter of 0.075 mm from rolled wire obtained by rolling at the third mill, the technological modes of drawing were studied. On the first mill, wire drawing was carried out from a diameter of 3.50 mm to a diameter of 1.45 mm. Then, after annealing on the second mill, drawing was carried out from a diameter of 1.45 mm to a diameter of 0.175 mm. Next, the wire was subjected to copper plating, and at the third stage, a wire of a given diameter was obtained according to the modes obtained by computer simulation. During drawing, wire breaks were not observed, and its properties met the requirements of regulatory documents for wire from palladium alloys intended for the manufacture of catchment gauzes.

Similar content being viewed by others

References

GOST R54151–2010 (2012) Platinum alloys catalytic gauzes. Specifications. https://docs.cntd.ru/document/1200085590. Accessed 12 Apr 2022

Fjellvåg AS, Waller D, Skjelstad J, Sjåstad AO (2019) Grain reconstruction of palladium and palladium-nickel alloys for platinum catchment. Johnson Matthey Technology Review 63(4):236–246. https://www.technology.matthey.com/article/63/4/236-246/. Accessed 12 Apr 2022

Rdzawski Z, Ciura L, Nikiel B (1995) Metallographic examination of catalyst gauzes and catchment gauzes from platinum and palladium alloys. J Mater Process Technol 53(1–2):319–329. https://doi.org/10.1016/0924-0136(95)01989-R. Accessed 12 Apr 2022

Fierro JLG, Palacios JM, Tomas F (1992) Characterization of catalyst and catchment gauzes used in medium- and low-pressure ammonia oxidation plants. J Mater Sci 27:685–691. https://doi.org/10.1007/BF02403880. Accessed 12 Apr 2022

TS 1995–091–00196533–2006 (2006) Woven catchment gauzes from palladium alloys

Pura J, Kwaśniak P, Jakubowska D, Jaroszewicz J, Zdunek J, Garbacz H, Mizera J, Gierej M, Laskowski Z (2013) Investigation of degradation mechanism of palladium-nickel wires during oxidation of ammonia. Catal Today 208:48–55. https://doi.org/10.1016/j.cattod.2012.11.014. Accessed 12 Apr 2022

Ivanović AT, Trumić BT, Ivanov SL, Marjanović SR, Zrilić MM, Volkov-Husović TD, Petković BB (2016) Optimisation of the recrystallisation annealing regime of Pd-5Ni alloy. Journal Johnson Matthey Technol Rev 60(1):31–38. https://doi.org/10.1595/205651315X689964. Accessed 12 Apr 2022

Bagmut AG, Shipkova IG, Zhuchkov VA (2011) Formation, structure, and magnetic changes at annealing of films deposited by laser sputtering of Ni and Pd. Journal of Surface Investigation 5(3):460–464. https://doi.org/10.1134/S1027451011050053. Accessed 12 Apr 2022

Pavlov EA, Gurskaya VY, Gushchinskiy AA, Efimov VN (2010) Substantiation and choice of cooling conditions for PdN-5 alloy during ingot solidification. Tsvetn Met 11:46–50. https://www.rudmet.ru/journal/488/article/4756/. Accessed 12 Apr 2022

Gang C, Peng Z, Hongwei L (2014) Molecular dynamics simulation of solidification of Pd-Ni clusters with different nickel content. Adv Mater Sci Eng 926206. https://doi.org/10.1155/2014/926206. Accessed 12 Apr 2022

Flanagan TB, Noh H, Wang D (2018) Hydrogen isotherms for compositionally homogeneous and inhomogenous Pd1−xNix alloys. J Alloy Compd 750:599–606. https://doi.org/10.1016/j.jallcom.2018.02.180. Accessed 12 Apr 2022

Kang Z, Zhao M, Wu Y, Xia T, Cao J-P, Cai W, Chen L (2019) Facial fabrication of yolk-shell Pd-Ni-P alloy with mesoporous structure as an advanced catalyst for methanol electro-oxidation. Appl Surf Sci 484:441–445. https://doi.org/10.1016/j.apsusc.2019.04.091. Accessed 12 Apr 2022

Guo M, Wang H, Cui L, Zhang J, Xiang Y, Lu S (2019) Nickel promoted palladium nanoparticles for electrocatalysis of carbohydrazide oxidation reaction. Small 15(28):1900929. https://doi.org/10.1002/smll.201900929. Accessed 12 Apr 2022

Konstantinov IL, Sidelnikov SB, Ivanov EV (2014) Rolling-press-drawing production: a textbook for universities in the direction of training metallurgy. SibFU, Krasnoyarsk. https://bik.sfu-kras.ru/shop/publication?id=BOOK1-621.77/%D0%9A%20650-797711306. Accessed 12 Apr 2022

Dovzhenko NN, Sidelnikov SB, Biront VS, Rudnitsky EA, Khodukov BP, Stolyarov AV (2008) The peculiarities of jewellery alloys obtaining and treating based on palladium. Vestnik of Nosov Magnitogorsk State Technical University 1:63–67. https://elibrary.ru/download/elibrary_10008110_30685555.pdf. Accessed 12 Apr 2022

Dovzhenko NN, Sidelnikov SB, Biront VS, Rudnitskij EA, Stoljrov AV, Uskov IV, Hodjukov BP (2008) The technology elaboration of the jewellery manufacture from nonsilver palladium alloys. Vestnik of Nosov Magnitogorsk State Technical University 3:64–66. https://elibrary.ru/download/elibrary_11654274_10664346.pdf. Accessed 12 Apr 2022

Rudnitskij EA, Dovzhenko NN, Khodyukov BP (2009) Study of the properties of new palladium alloys and improvement of their processing technology. Vestnik of Nosov Magnitogorsk State Technical University 3:41–44. https://elibrary.ru/download/elibrary_12860919_66925332.pdf. Accessed 12 Apr 2022

Sidelnikov SB, Dovzhenko NN, Ditkovskaya YD, Lopatina ES, Lebedeva OS, Rudnitsky EA (2015) Creation of new jewelry alloys from multicomponent precious-metal systems and their processing technologies. Vestnik of Nosov Magnitogorsk State Technical University 4:38–44. https://elibrary.ru/download/elibrary_24986667_91840951.pdf. Accessed 12 Apr 2022

GOST R52244-2004 (2004) Refined palladium. Specifications. https://meganorm.ru/Data/58/5829.pdf. Accessed 12 Apr 2022

GOST 849–2018 (2018) Primary nickel. Specifications. https://docs.cntd.ru/document/1200159303. Accessed 12 Apr 2022

DEFORM® Official website. https://www.deform.com/. Accessed 12 Apr 2022

Kolbasnikov NG, Matveev MA, Glukhov PA, Zotov OG, Korchagin AM (2016) Investigation of reasons of surface fissures formation during thick sheets rolling and microalloyed steel pipes manufacturing. Peculiarities of rolling in two-phase area. Stal 7:34–40. https://elibrary.ru/download/elibrary_27650306_16912820.pdf. Accessed 12 Apr 2022

Kolbasnikov NG, Mishin VV, Shishov IA, Kistankin IS, Zabrodin AV (2014) Development of nondestructive warm rolling schedules for nanocrystalline beryllium using mathematical simulation. Russ Metall 10:785–792. https://doi.org/10.1134/S0036029514100048. Accessed 12 Apr 2022

Cockcroft MG, Latham DJ (1968) Ductility and the Workability of Metals. J Inst Met 96:33–39

Mishin VV, Matveev MA, Kolbasnikov NG, Shishov IA, Glukhov PA (2016) Method for determining the limit values of the normalized Cockcroft-Latham failure criterion. Patent RU 2595821 C1. https://www.fips.ru/registers-doc-view/fips_servlet?DB=RUPAT&DocNumber=2595821&TypeFile=html. Accessed 12 Apr 2022

Botkin AV, Valiev RZ, Stepin PS, Baymukhametov AK (2011) Estimation of metal damage under cold plastic deformation using the Cockcroft-Latham fracture model. Deformation and destruction of materials 7:17–22

Matveev MA (2017) Numerical estimation of the probability of metal failure under hot plastic deformation by means of the Cockroft-Latham criterion. Scientific-technical Bulletin of SPbSPU. Nat Eng Sci 23(2):109–126. https://elibrary.ru/item.asp?id=29819963. Accessed 12 Apr 2022

Konstantinov IL, Baranov VN, Sidelnikov SB, Arnautov AD, Voroshilov DS, Dovzenko NN, Zenkin EY, Bezrukikh AI, Dovzenko IN, Yuryev PO (2021) Investigation of cold rolling modes of 1580 alloy by the method of computer simulation. Int J Adv Manuf Technol 112(7):1965–1972. https://doi.org/10.1007/s00170-020-06570-6. Accessed 12 Apr 2022

Sidelnikov S, Bindareva K, Lopatina E, Leonov V, Voroshilov D, Lebedeva O, Rudnitskiy E, Lopatin V (2019) Computer simulation and analysis of the parameters of the drawing process of thin wire from the alloy PD-5Ni. Key Eng Mater 805:13–18. https://doi.org/10.4028/www.scientific.net/KEM.805.13. Accessed 12 Apr 2022

Sidelnikov S, Lopatin V, Dobrovenko M, Lopatina E, Sokolov R (2020) Study of the stress-strain state of the process of drawing wire from an alloy of palladium with nickel. Mater Sci Forum 992:504–510. https://doi.org/10.4028/www.scientific.net/MSF.992.504. Accessed 12 Apr 2022

Funding

The research was carried out within the framework of the state assignment of the Ministry of Science and Higher Education of the Russian Federation (scientific theme code FSRZ-2020–0013).

Author information

Authors and Affiliations

Contributions

The authors declare that they are all participants in the work and none of them performed only administrative functions.

Corresponding author

Ethics declarations

Ethical approval

The work contains no libelous or unlawful statements, does not infringe on the rights of others, or contain material or instructions that might cause harm or injury.

Consent to participate

The authors consent to participate.

Consent to publish

The authors consent to publish.

Competing Interests

The authors declare no competing interests.

Availability of data and materials

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Konstantinov, I.L., Sidelnikov, S.B., Lopatina, E.S. et al. Investigation modes for production technology of wire from the Pd5Ni alloy for catchment gauzes of the chemical industry. Int J Adv Manuf Technol 121, 7229–7246 (2022). https://doi.org/10.1007/s00170-022-09821-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09821-w