Abstract

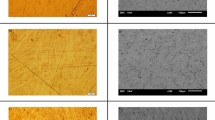

The non-oriented Fe-6.5wt.%Si alloy cast strip with a width of 100 mm and a thickness of 1.7 mm was prepared by the top side-pouring twin-roll-casting (TSTRC) process. The surface quality of the air-cooled and water-cooled cast strip was good. Compared with the Fe-6.5wt.%Si alloy ingot, the Fe-6.5wt.%Si alloy cast strip has a fine solidification structure and exhibits certain plasticity at room temperature. Microhardness, XRD, and TEM investigated the ordered structure and degree of Fe-6.5wt.%Si alloys prepared by three different cooling methods. The results show that the Fe-6.5wt.%Si alloy ingot prepared by the standard method has many B2-ordered phases and D03-ordered phases, and the order degree is high. The Fe-6.5wt.%Si alloy cast strip prepared by the TSTRC process has a low degree of order and only contains a small B2-ordered phase. The faster cooling rate effectively inhibits the formation of the D03-ordered phase and B2-ordered phase. The growth of the ordered phase also reduces the reverse domain boundary energy, reduces the motion resistance of superdislocations, and increases its mobility, thereby improving the room temperature plasticity of Fe-6.5wt.%Si alloy cast strips.

Similar content being viewed by others

Data availability

The data used to support the findings of this study are included within the article.

References

Zhang ZH, Wang WP, Fu HD, Xie JX (2011) Effect of quench cooling rate on residual stress, microstructure and mechanical property of an Fe–6.5Si alloy. Mat Sci Eng A 530:519–524. https://doi.org/10.1016/j.msea.2011.10.013

Littmann MF (1971) Iron and silicon-iron alloys. IEEE T Magn 7(1):48–60. https://doi.org/10.1109/TMAG.1971.1066998

Arai KI, Ishiyama K (1994) Recent developments of new soft magnetic materials. J Magn Magn Mater 133(1–3):233–237. https://doi.org/10.1016/0304-8853(94)90534-7

Li HZ, Liu HT, Liu Y, Liu ZY, Cao GM, Luo ZH, Zhang FQ, Chen SL, Li L, Wang GD (2014) Effects of warm temper rolling on microstructure, texture and magnetic properties of strip-casting 6.5 wt% Si electrical steel. J Magn Magn Mater 370:6–12. https://doi.org/10.1016/j.jmmm.2014.06.053

Shin JS, Bae JS, Kim HJ (2005) Ordering–disordering phenomena and micro-hardness characteristics of B2 phase in Fe (5–6.5%)Si alloys. Mat Sci Eng A 407(1/2):282–290. https://doi.org/10.1016/j.msea.2005.07.012

Liang YF, Ye F, Lin JP, Wang YL, Chen GL (2010) Effect of annealing temperature on magnetic properties of cold rolled high silicon steel thin sheet. J Alloy Compd 491(1–2):268–270. https://doi.org/10.1016/j.jallcom.2009.10.118

Ros T, Houbaert Y, Fischer O, Schneider J (2003) Production of high silicon steel for electrical applications by thermomechanical processing. J Mater Process Tech 143:916–921. https://doi.org/10.1016/S0924-0136(03)00247-4

Ros T, Ruiz D, Barros J, Houbaert Y (2004) Advances in the production of high-silicon electrical steel by thermomechanical processing and by immersion and diffusion annealing. J Alloy Compd 369(1–2):125–130. https://doi.org/10.1016/j.jallcom.2003.09.070

Liu J L, Sha Y H, Zhang F, Yang HP (2011) Development of strong {001}<210> texture and magnetic properties in Fe–6.5wt.%Si thin sheet produced by rolling method. J Appl Phys 109(7):385. https://doi.org/10.1063/1.3560894

Wittig JE, Frommeyer G (2008) Deformation and fracture behavior of rapidly solidified and annealed iron-silicon alloys. Metall Mater Trans A 39(2):252–265. https://doi.org/10.1007/s11661-007-9436-7

Li R, Shen Q, Zhang LM, Zhang T (2004) Magnetic properties of high silicon iron sheet fabricated by direct powder rolling. J Magn Magn Mater 281(2–3):135–139. https://doi.org/10.1016/j.jmmm.2004.04.098

Yuan WJ, Li JG, Shen Q, Zhang LM (2008) A study on magnetic properties of high Si steel obtained through powder rolling processing. J Magn Magn Mater 320(1–2):76–80. https://doi.org/10.1016/j.jmmm.2007.05.008

Okada K, Yamaji T, Kasai K (1996) Basic investigation of cvd method for manufacturing 6.5% Si steel sheet. ISIJ Int 36(6):706–713. https://doi.org/10.2355/isijinternational.36.706

Yamaji T, Abe M, Takada Y, Okada K, Hiratani T (1994) Magnetic properties and workability of 6.5% silicon steel sheet manufactured in continuous cvd siliconizing line. J Magn Magn Mater 133(1–3):187–189. https://doi.org/10.1016/0304-8853(94)90521-5

Abe M, Takada Y, Murakami T, Tanaka Y, Mihara Y (1989) Magnetic properties of commercially produced Fe-6.5wt% Si sheet. J Mater Civil Eng 11(1):109–116. https://doi.org/10.1007/BF02833761

Arai KI, Tsutsumitake H, Ohmori K (1984) Grain growth and texture formation by annealing of rapidly quenched high silicon-iron alloy. J Jpn I Met Mater 48(5):482–488. https://doi.org/10.2320/jinstmet1952.48.5_482

Arai KI, Tsuya N, Ohmori K, Shimanaka H, Miyazaki T (1980) Rapidly quenched ribbon-form silicon-iron alloy with high silicon concentration. J Magn Magn Mater 15:1425–1426. https://doi.org/10.1016/0304-8853(80)90352-2

Raviprasad K, Chattopadhyay K (1988) The effect of rapid solidification on the order-disorder transformation in iron-based alloys. Mat Sci Eng A 98(98):281–284. https://doi.org/10.1016/0025-5416(88)90170-X

Fu HD, Zhang ZH, Yang Q, Xie JX (2011) Strain-softening behavior of an Fe–6.5 wt%Si alloy during warm deformation and its applications. Mat Sci Eng A 528:1391–1395. https://doi.org/10.1016/j.msea.2010.10.093

Fu HD, Zhang ZH, Jiang YB, Xie JX (2011) Improvement of magnetic properties of an Fe–6.5wt.% Si alloy by directional solidification. Mater Lett 65(9):1416–1419. https://doi.org/10.1016/j.matlet.2011.02.020

Xie JX, Fu HD, Zhang ZH, Jiang YB (2012) Deformation twinning feature and its effects on significant enhancement of tensile ductility in columnar-grained Fe–6.5wt.%Si alloy at intermediate temperatures. Intermetallics 23:20–26. https://doi.org/10.1016/j.intermet.2011.12.011

Wang XL, Li HZ, Zhang WN, Liu ZY, Wang GD, Luo ZH, Zhang FQ (2016) The work softening by deformation-induced disordering and cold rolling of 6.5 wt.% Si steel thin sheets. Metall Mater Trans A 47(9):4659-4668. https://doi.org/10.1007/s11661-016-3613-5

Gupta M, Sahai Y (2007) Mathematical modeling of fluid flow, heat transfer, and solidification in two-roll melt drag thin strip casting of steel. ISIJ Int 40(2):144–152. https://doi.org/10.2355/isijinternational.40.144

Liu HT, Liu ZY, Sun Y, Fei G, Wang GD (2013) Development of λ-fiber recrystallization texture and magnetic property in Fe–6.5 wt% Si thin sheet produced by strip casting and warm rolling method. Mater Lett 91(15):150–153. https://doi.org/10.1016/j.matlet.2012.09.046

Wang D, Zhou C (2014) A top side-pouring twin-roll caster for metals strips. J Mater Process Tech 214(4):916–924. https://doi.org/10.1016/j.jmatprotec.2013.12.001

Alcalá J, Barone CA, Anglada M (2000) The influence of plastic hardening on surface deformation modes around vickers and spherical indents. Acta Mater 48:3451–3464. https://doi.org/10.1016/S1359-6454(00)00140-3

Marcinkowski MJ, Brown N (1962) Direct observation of antiphase boundaries in the Fe3Al superlattice. J Appl Phys 33(2):537–552. https://doi.org/10.1063/1.1702463

Ustinovshchikov YI, Sapegina IV (2005) Ordering of Fe-Si phases. Inorg Mater 41(1):24–31. https://doi.org/10.1007/s10789-005-0006-3

Viala B, Degauque J, Fagot M, Baricco M, Ferrara E, Fiorillo F (1996) Study of the brittle behaviour of annealed Fe-6.5 wt%Si ribbons produced by planar flow casting. Mat Sci Eng A 212(1):62–68. https://doi.org/10.1016/0921-5093(96)10188-X

Yoshimi K, Terashima H, Hanada S (1995) Effect of APB type on tensile properties of Cr added Fe3Al with DO3 structure. Mat Sci Eng A 194(1):53–61. https://doi.org/10.1016/09215093(94)09659-7

Marcinkowski MJ, Fisher RM (1963) Theoretical analysis of plastic deformation in superlattices based on the body-centered cubic structure. J Appl Phys 34(8):2135–2145. https://doi.org/10.1063/1.1702703

Marcinkowski MJ, Brown N (1961) Theory and direct observation of dislocations in the Fe3Al superlattices. Acta Metall 9(8):764–786. https://doi.org/10.1016/0001-6160(61)90107-9

Raviprasad K, Aoki K, Chattopadhyay K (1993) The nature of dislocations and effect of order in rapidly solidified Fe (5.5-7.5)wt.%Si alloys. Mat Sci Eng A 172(1–2):125–135. https://doi.org/10.1016/0921-5093(93)90432-E

Lakso GE, Marcinkowski MJ (1974) Plastic deformation in Fe-Si alloys. Metall Mater Trans A 5(4):839–845. https://doi.org/10.1007/BF02643136

Funding

This work was supported by the Key Technologies Research and Development Program(2021YFB3800502).

Author information

Authors and Affiliations

Contributions

Cheng Zhou contributed to the conception of the study; Dongpo Xuan performed the experiment, contributed significantly to analysis and manuscript preparation, performed the data analyses, and wrote the manuscript; others helped perform the analysis with constructive discussions.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

All authors agreed with the consent to participate.

Consent to publish

That the work described has not been published before (except in the form of an abstract or as part of a published lecture, review, or thesis). That it is not under consideration for publication elsewhere; that its publication has been approved by all co-authors, if any; that its publication has been approved (tacitly or explicitly) by the responsible authorities at the institution where the work is carried out.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xuan, D., Zhou, C., Zhou, Y. et al. Effects of Fe-6.5wt.%Si alloys prepared by different cooling methods on ordered structure and mechanical properties. Int J Adv Manuf Technol 131, 5679–5689 (2024). https://doi.org/10.1007/s00170-022-09761-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09761-5