Abstract

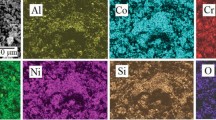

A grain fine surface plastic deformation layer with a thickness of about 108.6 ± 1.5 μm was fabricated on 20Cr2Ni4A steel by supersonic fine particle bombardment (SFPB). The microstructure, wettability, and tribological properties of original and SFPB-treated (including Co-SFPB samples: activated carbon was added to the bombarded powder (Al2O3) followed by SFPB; Precoat + SFPB samples: the activated carbon is precoated on the surface of the original material followed by SFPB) low carbon steel were characterized by optical microscope (OM), scanning electron microscope (SEM), static water contact angle, friction, and wear test. The results show that SFPB can refine the surface microstructure and the grain size is about 21 nm. The surface hardness is as high as 428.1 HV0.2, which is 89.3% higher than the original samples. Compared with the residual stress of the original samples (− 116.7 MPa), the residual stress on the surface of Precoat + SFPB samples (− 333.8 MPa) is significantly increased. The measurement results of static water contact angle illustrate that Precoat + SFPB samples have the best hydrophobicity (133.4°). After the treatment of SFPB, 20Cr2Ni4A steel is worn for a certain time, combined with the comprehensive analysis results of friction coefficient, mass loss, and wear morphology, Precoat + SFPB samples have the best wear resistance, which is due to its high surface hardness, large residual compressive stress, and the alloying layer formed by pre-coating activated carbon under the SFPB.

Similar content being viewed by others

Availability of data and materials

The data sets supporting the results of this article are included within the article.

Code availability

Not applicable.

References

Jena G, George RP, Philip J (2021) Fabrication of a robust graphene oxide-nano SiO2-polydimethylsiloxane composite coating on carbon steel for marine applications. Prog Org Coat 161

Dong B, Liu W, Zhang T, Chen L, Fan Y, Zhao Y, Yang W, Banthukul W (2021) Corrosion failure analysis of low alloy steel and carbon steel rebar in tropical marine atmospheric environment: outdoor exposure and indoor test. Eng Failure Anal 129

Hou W, Liu QD, Gu JF (2020) Improved impact toughness by multi-step heat treatment in a 1400 MPa low carbon precipitation-strengthened steel. Mat Sci Eng A-Struct 797:140077

Cao Z, Liu T, Yu F, Cao W, Zhang X, Weng Y (2020) Carburization induced extra-long rolling contact fatigue life of high carbon bearing steel. Int J Fatigue 131:105351.1–105351.6

Shi L, Cui X, Li J, Jin G, Liu J, Tian H (2022) Improving the wear resistance of heavy-duty gear steels by cyclic carburizing. Tribol Int. https://doi.org/10.1016/j.triboint.2022.107576

Li GM, Liang YL, Sun H, Cao YG (2020) Nitriding behavior and mechanical properties of carburizing and nitriding duplex treated M50NiL steel. Surf Coat Tech 384:125315

Duan Y, Qu SG, Jia SY, Li XQ (2021) Effects of ultrasonic surface rolling processing on microstructure and wear properties of high-carbon high-chromium steel. Surf Coat Tech 422:127531

Ma YF, Xiong Y, Chen ZG, Zha XQ, He TT, Li Y, Singh H, Kömi J, Huttula M, Cao W (2021) Microstructure evolution and properties of gradient nanostructures subjected to laser shock processing in 300M ultrahigh-strength steel. Steel Res Int 2100434

Walczak M, Szala M (2021) Effect of shot peening on the surface properties, corrosion and wear performance of 17–4PH steel produced by DMLS additive manufacturing, Arch Civ Mech Eng 21

Wen X, Cui X, Jin G, Liu Y, Zhang Y, Zhang X, Liu E, Tian H, Fang Y (2022) Corrosion and tribo-corrosion behaviors of nano-lamellar Ni1.5CrCoFe0.5Mo0.1Nbx eutectic high-entropy alloy coatings: the role of dual-phase microstructure. Corros Sci. https://doi.org/10.1016/j.corsci.2022.110305

Li X, Nakatani M, Yang J, Zhang J, Sharma B, Pan H, Ameyama K, Fang J, Zhu X (2022) Investigation of mechanical properties and microstructural evolution in Cu-Al alloys with gradient structure. J Alloys Compd 890

Song J, Luo S, Liang X, Cao Z, Zhao W, Pu C, He W (2022) Rolling contact fatigue and damage characteristic of AISI 9310 steel with pre-laser shock peening treatment. Int J Fatigue 155

Meng Y, Deng J, Zhang Y, Wang S, Li X, Yue H, Ge D (2020) Tribological properties of textured surfaces fabricated on AISI 1045 steels by ultrasonic surface rolling under dry reciprocating sliding. Wear 460–461:203488

Zhou T, Xiong Y, Chen ZG, Zha XQ, Lu Y, He TT, Ren FZ, Singh H, Komi J, Huttula M, Cao W (2021) Effect of surface nano-crystallization induced by supersonic fine particles bombarding on microstructure and mechanical properties of 300M steel. Surf Coat Tech 421:127381

Cui ZQ, Mi YJ, Qiu D, Dong P, Qin Z, Gong DQ, Li WG (2021) Microstructure and mechanical properties of additively manufactured CrMnFeCoNi high-entropy alloys after ultrasonic surface rolling process. J Alloys Compd 887:161393

Yu H, Liang W, Miao Q, Yin M, Ma Y, Zuo S (2021) Effect of shot peening pretreatment on the high-temperature tribological behaviours of a TaN coating prepared via double-cathode glow plasma alloying. Surf Coat Tech 427

Lu H, Ren Y, Chen Y, Zhu H, Xin Z, Wan H, Li Z, Tu X, Cheng L, He K, Han Q, Ye Y, Ren X (2021) Wear resistance of 20Cr2Ni4A alloy steel treated by laser shock peening and implantation of diamond nanoparticles. Surf Coat Tech 412:127070

Ren K, Yue W, Zhang H (2018) Surface modification of Ti6Al4V based on ultrasonic surface rolling processing and plasma nitriding for enhanced bone regeneration. Surf Coat Tech 349:602–610

Ge LL, Tian N, Lu ZX, You CY (2013) Influence of the surface nanocrystallization on the gas nitriding of Ti-6Al-4V alloy. Appl Surf Sci 286:412–416

Tao YS, Xiong TY, Sun C, Kong LY, Cui XY, Li TF, Song GL (2010) Microstructure and corrosion performance of a cold sprayed aluminium coating on AZ91D magnesium alloy. Corros Sci 52:3191–3197

Wu Y, Xiong Y, Liu W, Chen Z, Zhang X, Wang S, Cao W (2021) Effect of supersonic fine particle bombardment on microstructure and fatigue properties of Ti-6.5Al-3.5Mo-1.5Zr-0.3Si titanium alloy at different temperatures. Surf Coat Tech 421:127473

Lao Y, Du H, Xiong T, Wang Y (2017) Evolution behaviors of oxides in severely plastic deformed region of AISI 52100 steel during dry sliding wear. J Mater Sci Technol 33:330–337

Wang Z, Xing Z, Wang H, Shan D, Huang Y, Xu Z, Xie F (2022) The relationship between inclusions characteristic parameters and bending fatigue performance of 20Cr2Ni4A gear steel. Int J Fatigue 155

Ablyaz TR, Shlykov ES, Muratov KR, Mahajan A, Singh G, Devgan S, Sidhu SS (2020) Surface characterization and tribological performance analysis of electric discharge machined duplex stainless steel. Micromachines 11:926

Azevedo AF, Corat EJ, Ferreira NG, Trava-Airoldi VJ (2005) Wettability and corrosion tests of diamond films grown on Ti6Al4V alloy. Surf Coat Tech 194:271–275

Yao L, Dai P, Ouyang L, Zhu L (2021) A sensitive and reproducible SERS sensor based on natural lotus leaf for paraquat detection. Microchem J 160:105728

Wang C, Shao R, Wang G, Sun S (2011) Hierarchical hydrophobic surfaces with controlled dual transition between rose petal effect and lotus effect via structure tailoring or chemical modification. Colloids Surf A 622:126661

Zhang P, Yin X, Li W, Feng L (2021) Feng, Preparation, properties and formation mechanism of zirconium-Si hybrid high transmittance hydrophobic coating. Colloids Surf A 631:127649

Kumar D, Idapalapati S, Wang W, Child DJ, Haubold T, Wong CC (2019) Microstructure-mechanical property correlation in shot peened and vibro-peened Ni-based superalloy. J Mater Process Tech 267:215–229

Hou JX, Li XY, Lu K (2021) Orientation dependence of mechanically induced grain boundary migration in nano-grained copper. J Mater Sci Technol 68:30–34

Suo N, Sun A, Yu L, Zuo Z, Zhao X, Zhang W, Zhang Y, Shao L, Yu T (2020) Preparation and study of lattice structure and magnetic properties of Bi3+ ion-doped Ni-Mg-Co ferrites by sol-gel auto-combustion method. J Sol-Gel Sci Techn 95:360–374

Liu H, Wei G, Xu Z, Liu P, Li Y (2016) Quantitative analysis of Fe and Co in Co-substituted magnetite using XPS: the application of non-linear least squares fitting (NLLSF). Appl Surf Sci 389:438–446

Huang K, Bi K, Liang C, Lin S, Zhang R, Wang WJ, Tang HL, Lei M (2015) Novel VN/C nanocomposites as methanol-tolerant oxygen reduction electrocatalyst in alkaline electrolyte. Sci Rep 5:11351

Zhang X, Wang C, Yu C, Teng B, He Y, Zhao L, Fan M (2018) Application of Ag/AgBr/GdVO4 composite photocatalyst in wastewater treatment. J Environ Sci 63:68–75

Cai Z, Chen R, Wang W, Qian J, Guo W, Pu J (2020) Microstructure and tribological properties of Cu-doped VCN films: the role of Cu. Appl Surf Sci 510:145509

Gautam J, Thanh TD, Maiti K, Kim NH, Lee JH (2018) Highly efficient electrocatalyst of N-doped graphene-encapsulated cobalt-iron carbides towards oxygen reduction reaction. Carbon 137:358–367

Luna ML, Timoshenko J, Kordus D, Rettenmaier C, Chee SW, Hoffman AS, Bare SR, Shaikhutdinov S, Cuenya BR (2021) Role of the oxide support on the structural and chemical evolution of Fe catalysts during the hydrogenation of CO2. Acs Catal 11:6175–6185

Guan JJ, Wang HQ, Qin LZ, Liao B, Liang H, Li B (2017) Phase transitions of doped carbon in CrCN coatings with modified mechanical and tribological properties via filtered cathodic vacuum arc deposition. Nucl Instrum Meth B 397:86–91

Caicedo JC, Aperador W, Amaya C (2017) Determination of physical characteristic in vanadium carbon nitride coatings on machining tools. Int J Adv Manuf Tech 91:1227–1241

Liu K, Cui X, Dong M, Xing Z, Li J, Tian H, Jin G, Wang H, Xu B (2021) Mechanism of diffusion promotion of carbon atoms during carburization of 20Cr2Ni4A alloy steel after lanthana-bearing supersonic fine particle bombarding pretreatment. Surf Coat Tech 425:127702

Yao H, Xie Z, Huang C, Yuan Q, Yu Z (2021) Recent progress of hydrophobic cement-based materials: preparation, characterization and properties. Constr Build Mater 299:124255

Funding

This work was financially supported by the National Natural Science Foundation of China (No. 51975137, 52175163), Foundation of National Key Laboratory for Precision Hot Processing of Metal and Fundamental Research Funds for the Central Universities.

Author information

Authors and Affiliations

Contributions

Lei Shi: methodology, investigation, writing—original draft. Jinna Liu: investigation, writing—review & editing. Jian Li: investigation, writing—review & editing. Zuo Wang: methodology, writing—review & editing. Xiufang Cui: resources, writing—review & editing, supervision, funding acquisition. Guo Jin: resources, writing—review & editing, supervision, funding acquisition. Haoliang Tian: writing—review & editing.

Corresponding authors

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shi, L., Liu, J., Li, J. et al. Enhanced wear resistance and wettability of 20Cr2Ni4A steel by supersonic fine particle bombardment treatment. Int J Adv Manuf Technol 121, 6193–6204 (2022). https://doi.org/10.1007/s00170-022-09740-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09740-w