Abstract

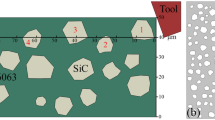

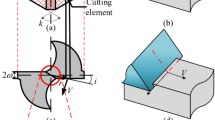

Particle reinforced aluminum matrix (SiCp/Al) composite has been one of the promising engineering materials due to its excellent mechanical and thermal characteristics. However, their poor machinability greatly limits the wide applications due to the existence of hard abrasive particles. This paper contributes to the current literatures by systematically studying the effect of a wide range of particle volume fraction (Pvf) on the machinability in dry drilling of SiCp/Al composites and finding the variation characteristic of machinability for the first time. Specifically, tool wear characteristics, chip formation characteristics, machining damage characteristics including hole entrance, hole exit, hole wall, and particle damage are comprehensively analyzed, and the corresponding formation mechanisms are revealed. Combined with the analysis of variance (ANOVA), the importance of the experimental parameters on machinability indicators is obtained. The results show that Pvf contributes 44.1%, 74.1%, and 74.2% to cutting force, burr height, and surface roughness, respectively, and maintain a strong linear relationship with the three indicators. Chip topography analysis found that C-chip, conical spiral chip, curls chip, and fan chip were under low Pvf, and gradually changed to only fan chip under high Pvf. The burr on the hole exit gradually turns into edge breakage with the increase of Pvf. The main reason for the variation characteristic of machinability is concluded to be the variation of the ductility-brittleness of the materials with increase in Pvf. In addition, microstructural analysis shows that the particle damage characteristics comprise squeezing, debonding, squeezing fracture, and shear fracture.

Similar content being viewed by others

Data availability

All data generated or analyzed during this paper are included in this published article.

Code availability

Not applicable.

References

Dahnel AN, Ascroft H, Barnes S (2020) An investigation of hole quality during drilling of carbon fibre reinforced plastic and titanium (Ti6Al4V) using tungsten carbide drills. Mater Today Proc 29:161–167. https://doi.org/10.1016/j.matpr.2020.05.640

Bai W, Roy A, Sun R, Silberschmidt VV (2019) Enhanced machinability of SiC-reinforced metal-matrix composite with hybrid turning. J Mater Process Technol 268:149–161. https://doi.org/10.1016/j.jmatprotec.2019.01.017

Jayaraman P, Kumar LM(2014) Multi-response optimization of machining parameters of turning AA6063 T6 aluminium alloy using grey relational analysis in taguchi method. Procedia Eng 97:197–204. https://doi.org/10.1016/j.proeng.2014.12.242

Davis JM, Saei M, Mohanty DP, Udupa A, Sugihara T, Chandrasekar S (2020) Cutting of tantalum: why it is so difficult and what can be done about it. Int J Mach Tools Manuf 157:103607. https://doi.org/10.1016/j.ijmachtools.2020.103607

Abdulgadir MM, Demir B, Turan ME (2018) Hybrid reinforced magnesium matrix composites (Mg/Sic/GNPs): drilling investigation. Metals 8:215. https://doi.org/10.3390/met8040215

Liao Z, Abdelhafeez A, Li H, Yang Y, Diaz OG, Axinte D (2019) State-of-the-art of surface integrity in machining of metal matrix composites. Int J Mach Tools Manuf 143:63–91. https://doi.org/10.1016/j.ijmachtools.2019.05.006

Liu C, Gao L, Jiang X, Xu W, Liu S, Yang T (2020) Analytical modeling of subsurface damage depth in machining of SiCp/Al composites. Int J Mech Sci 185:105874. https://doi.org/10.1016/j.ijmecsci.2020.105874

Wu Q, Xu W, Zhang L (2019) Machining of particulate-reinforced metal matrix composites: an investigation into the chip formation and subsurface damage. J Mater Process Technol 274:116315. https://doi.org/10.1016/j.jmatprotec.2019.116315

Dandekar CR, Shin YC (2009) Multi-step 3-D finite element modeling of subsurface damage in machining particulate reinforced metal matrix composites. Compos Part Appl Sci Manuf 40:1231–1239. https://doi.org/10.1016/j.compositesa.2009.05.017

Anandan N, Ramulu M (2020) Study of machining induced surface defects and its effect on fatigue performance of AZ91/15%SiCp metal matrix composite. J Magnes Alloys 8:387–395. https://doi.org/10.1016/j.jma.2020.01.001

Chakaravarthy VVK, Rajmohan T, Vijayan D, Palanikumar K, Latha B (2020) Sustainable drilling performance optimization for Nano SiC reinforced Al matrix composites. Mater Manuf Process 35:1304–1312. https://doi.org/10.1080/10426914.2020.1772484

Reddy PV, Ramanjaneyulu P, Reddy BV, Rao PS (2020) Simultaneous optimization of drilling responses using GRA on Al-6063/TiC composite. SN Appl Sci 2:431. https://doi.org/10.1007/s42452-020-2214-5

Kumar P, Kumar BPV, Joshi R, Manjunatha TH (2018) Evaluation of Al7075 reinforced with SiC for its mechanical properties & surface roughness by drilling. Mater Today Proc 5:25121–25129. https://doi.org/10.1016/j.matpr.2018.10.313

Kumaran ST, Ko TJ, Uthayakumar M, Khan MA, Muhammad I (2017) Some experimental investigations on drilling AA (6351)-SiC-B 4 C composite. Mater Manuf Process 32:1557–1564. https://doi.org/10.1080/10426914.2017.1279311

Rajmohan T, Palanikumar K, Kathirvel M (2012) Optimization of machining parameters in drilling hybrid aluminium metal matrix composites. Trans Nonferrous Met Soc China 22:1286–1297. https://doi.org/10.1016/S1003-6326(11)61317-4

Adalarasan R, Santhanakumar M (2015) Application of taguchi based response surface method (TRSM) for optimization of multi responses in drilling Al/SiC/Al2O3 hybrid composite. J Inst Eng India Ser C 96:65–71. https://doi.org/10.1007/s40032-014-0124-2

Kamboj A, Kumar S, Singh H (2015) Burr height and hole diameter error minimization in drilling of AL6063/15%/SiC composites using HSS step drills. J Mech Sci Technol 29:2837–2846. https://doi.org/10.1007/s12206-015-0612-1

Huang ST, Zhou L, Chen J, Xu LF (2012) Drilling of SiCp/Al metal matrix composites with polycrystalline diamond (PCD) tools. Mater Manuf Process 27:1090–1094. https://doi.org/10.1080/10426914.2011.654152

Rajmohan T, Palanikumar K (2013) Modeling and analysis of performances in drilling hybrid metal matrix composites using D-optimal design. Int J Adv Manuf Technol 64:1249–1261. https://doi.org/10.1007/s00170-012-4083-6

Palanikumar K, Muniaraj A (2014) Experimental investigation and analysis of thrust force in drilling cast hybrid metal matrix (Al-15%SiC-4%graphite) composites. Measurement 53:240–250. https://doi.org/10.1016/j.measurement.2014.03.027

Karabulut Ş, Gökmen U, Çinici H (2016) Study on the mechanical and drilling properties of AA7039 composites reinforced with Al2O3/B4C/SiC particles. Compos Part B Eng 93:43–55. https://doi.org/10.1016/j.compositesb.2016.02.054

Ekici E, Motorcu AR, Uzun G (2017) An investigation of the effects of cutting parameters and graphite reinforcement on quality characteristics during the drilling of Al/10B 4 C composites. Measurement 95:395–404. https://doi.org/10.1016/j.measurement.2016.10.041

Singh S (2016) Effect of modified drill point geometry on drilling quality characteristics of metal matrix composite (MMCs). J Mech Sci Technol 30:2691–2698. https://doi.org/10.1007/s12206-016-0530-x

Samy GS, Kumaran ST (2017) Measurement and analysis of temperature, thrust force and surface roughness in drilling of AA (6351)-B 4 C composite. Measurement 103:1–9. https://doi.org/10.1016/j.measurement.2017.02.016

Ay M, Altunpak Y, Hartomacıoğlu S (2017) The grey-based taguchi method: optimisation of drilling of Hhbrid aluminum matrix composites. Acta Phys Pol A 131:551–555. https://doi.org/10.12693/APhysPolA.131.551

Xiang J, Xie L, Gao F, Yi J, Pang S, Wang X (2018) Diamond tools wear in drilling of SiCp/Al matrix composites containing Copper. Ceram Int 44:5341–5351. https://doi.org/10.1016/j.ceramint.2017.12.154

Thirukkumaran K, Menaka M, Mukhopadhyay CK, Venkatraman B (2020) A study on temperature rise, tool wear, and surface roughness during drilling of Al–5%SiC composite. Arab J Sci Eng 45:5407–5419. https://doi.org/10.1007/s13369-020-04427-4

Abbas CA, Huang C, Wang J, Wang Z, Liu H, Zhu H (2020) Machinability investigations on high-speed drilling of aluminum reinforced with silicon carbide metal matrix composites. Int J Adv Manuf Technol 108:1601–1611. https://doi.org/10.1007/s00170-020-05409-4

Rajkumar SE, Palanikumar K, Pitchandi K, Latha B (2020) Subsurface integrity studies on the drilling of Al/B 4 C/mica hybrid metal matrix composites. Mater Manuf Process 35:52–60. https://doi.org/10.1080/10426914.2020.1711918

Wang Z, Song M, Sun C, Xiao D, He Y (2010) Effect of extrusion and particle volume fraction on the mechanical properties of SiC reinforced Al-Cu alloy composites. Mater Sci Eng A 527:6537–6542. https://doi.org/10.1016/j.msea.2010.07.017

Krishnamurthy L, Sridhara BK, Budan DA (2007) Comparative study on the machinability aspects of aluminium silicon carbide and aluminium graphite composites. Mater Manuf Process 22:903–908. https://doi.org/10.1080/10426910701451754

Salur E, Aslan A, Kuntoglu M, Gunes A, Sahin OS (2019) Experimental study and analysis of machinability characteristics of metal matrix composites during drilling. Compos Part B Eng 166:401–413. https://doi.org/10.1016/j.compositesb.2019.02.023

Chawla N, Shen Y-L (2001) Mechanical behavior of particle reinforced metal matrix composites. Adv Eng Mater 3:357–370. https://doi.org/10.1002/1527-2648(200106)3:6%3c357::AID-ADEM357%3e3.0.CO;2-I

Ganesh VV, Chawla N (2005) Effect of particle orientation anisotropy on the tensile behavior of metal matrix composites: experiments and microstructure-based simulation. Mater Sci Eng, A 391:342–353. https://doi.org/10.1016/j.msea.2004.09.017

Ozcatalbas Y (2003) Investigation of the machinability behaviour of Al4C3 reinforced Al-based composite produced by mechanical alloying technique. Compos Sci Technol 63:53–61. https://doi.org/10.1016/S0266-3538(02)00177-X

Uddin M, Basak A, Pramanik A, Singh S, Krolczyk GM, Prakash C (2018) Evaluating hole quality in drilling of Al 6061 alloys. Materials 11:2443. https://doi.org/10.3390/ma11122443

Latha B, Senthilkumar VS (2009) Analysis of thrust force in drilling glass fiber-reinforced plastic composites using fuzzy logic. Mater Manuf Process 24:509–516. https://doi.org/10.1080/10426910802714688

Liu C, Xu W, Jin Y, Jiang XG, Yang T (2020) Mechanistic force modeling in drilling of SiCp/Al matrix composites considering a comprehensive abrasive particle model. Int J Adv Manuf Technol 109:421–442. https://doi.org/10.1007/s00170-020-05688-x

Prasanna J, Karunamoorthy L, Raman MV, Prashanth S, Chordia DR (2014) Optimization of process parameters of small hole dry drilling in Ti–6Al–4V using taguchi and grey relational analysis. Measurement 48:346–354. https://doi.org/10.1016/j.measurement.2013.11.020

Ucun İ (2016) 3D finite element modelling of drilling process of Al7075-T6 alloy and experimental validation. J Mech Sci Technol 30:1843–1850. https://doi.org/10.1007/s12206-016-0341-0

Liu C, Wang G, Ren C, Yang Y (2014) Mechanistic modeling of oblique cutting considering fracture toughness and thermo-mechanical properties. Int J Adv Manuf Technol 74:1459–1468. https://doi.org/10.1007/s00170-014-6100-4

Ghandehariun A, Kishawy H, Balazinski M (2016) On machining modeling of metal matrix composites: a novel comprehensive constitutive equation. Int J Mech Sci 107:235–241. https://doi.org/10.1016/j.ijmecsci.2016.01.020

Wang Z, Song M, Sun C, He Y (2011) Effects of particle size and distribution on the mechanical properties of SiC reinforced Al-Cu alloy composites. Mater Sci Eng A 528:1131–1137. https://doi.org/10.1016/j.msea.2010.11.028

Faraz A, Biermann D, Weinert K (2009) Cutting edge rounding: an innovative tool wear criterion in drilling CFRP composite laminates. Int J Mach Tools Manuf 49:1185–1196. https://doi.org/10.1016/j.ijmachtools.2009.08.002

Dwivedi SP, Srivastava AK, Maurya NK, Sahu R, Tyagi A, Maurya R (2020) Microstructure and mechanical behaviour of Al/SiC/Al2O3 hybrid metal matrix composite. Mater Today Proc 25:789–792. https://doi.org/10.1016/j.matpr.2019.09.023

Saravanakumar A, Sasikumar P, Sivasankaran S (2014) Effect of graphite particles in drilling of hybrid aluminum matrix composite. Procedia Eng 97:495–504. https://doi.org/10.1016/j.proeng.2014.12.274

Yarar E, Karabay S (2020) Investigation of the effects of ultrasonic assisted drilling on tool wear and optimization of drilling parameters. CIRP J Manuf Sci Technol 31:265–280. https://doi.org/10.1016/j.cirpj.2020.06.002

Gaitonde VN, Karnik SR, Davim JP (2015) Multiple performance optimization in drilling using Taguchi method with utility and modified utility concepts. Mater Form Mach Elsevier 99–115. https://doi.org/10.1016/B978-0-85709-483-4.00005-3

Yazman Ş, Köklü U, Urtekin L, Morkavuk S, Gemi L (2020) Experimental study on the effects of cold chamber die casting parameters on high-speed drilling machinability of casted AZ91 alloy. J Manuf Process 57:136–152. https://doi.org/10.1016/j.jmapro.2020.05.050

Costa ES, da Silva MB, Machado AR (2009) Burr produced on the drilling process as a function of tool wear and lubricant-coolant conditions. J Braz Soc Mech Sci Eng 31:57–63. https://doi.org/10.1590/S1678-58782009000100009

Liu S, Yang T, Liu C, Du Y (2019) Comprehensive investigation of cutting mechanisms and hole quality in dry drilling woven aramid fibre–reinforced plastic with typical tools. Proc Inst Mech Eng Part B J Eng Manuf 233:2471–2491. https://doi.org/10.1177/0954405419844855

Liu C, Ren C, Wang G, Yang Y, Zhang L (2015) Study on surface defects in milling Inconel 718 super alloy. J Mech Sci Technol 29:1723–1730. https://doi.org/10.1007/s12206-015-0345-1

Amran MA, Salmah S, Hussein NIS, Izamshah R, Hadzley M, Sivaraos KMS, Sulaiman MA (2013) Effects of machine parameters on surface roughness using response surface method in drilling process. Procedia Eng 68:24–29. https://doi.org/10.1016/j.proeng.2013.12.142

Xu J, Li C, Chen M, El Mansori M, Paulo Davim J (2020) On the analysis of temperatures, surface morphologies and tool wear in drilling CFRP/Ti6Al4V stacks under different cutting sequence strategies. Compos Struct 234:111708. https://doi.org/10.1016/j.compstruct.2019.111708

Acknowledgements

We would like to thank the Analytical & Testing Center of Tiangong University for structured illumination microscopy work.

Funding

This work is supported by the National Natural Science Foundation of China (No. 51705362), and Tianjin Research Innovation Project for Postgraduate Students (2021YJSB233).

Author information

Authors and Affiliations

Contributions

Chang Liu: Investigation, Methodology, Writing—original draft, Writing—review & editing; Cheng Li: Validation, Experiments, Writing—original draft, Writing—review & editing; Weiwei Xu: Methodology, Supervision, Writing—review & editing; Lei Gao: Experiments.

Corresponding authors

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, C., Li, C., Xu, W. et al. Variation characteristics of machinability in drilling of SiC particle reinforced aluminum matrix (SiCp/Al) composite with a wide range of particle volume fractions. Int J Adv Manuf Technol 121, 6285–6302 (2022). https://doi.org/10.1007/s00170-022-09731-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09731-x