Abstract

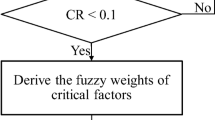

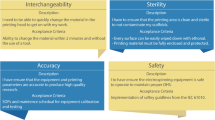

Polycaprolactone (PCL)-based scaffolds have great potential in various tissue engineering applications because of their biodegradability, high mechanical strength, and easy fabrication using different 3D printing methods. However, previous research has only focused on developing and examining each PCL-based scaffold printing method’s merits and limitations separately. Thus, the lack of a systematic comparison of the various methods to recommend the most appropriate one for each application remains. This paper provides an overview of different PCL-based scaffold printing methods. Four typical 3D printing methods for fabricating PCL-based scaffolds and five important evaluation criteria including quality, usage, productivity, cost, and flexibility are identified. The integrated fuzzy-analytical hierarchy process (i-FAHP) and sensitivity analysis are proposed as multi-criteria decision-making methods for selecting the most appropriate scaffold printing method (SPM) under constrained construction and material types. Customized software based on a flexible fuzzy-AHP expert system is built to support decision-makers in determining the optimal SPM quickly and effectively. The result shows that the melt-based extrusion method is optimal for different scaffold types. This study’s findings will be useful for developing biomaterial and multi-head 3D bioprinters for customized and commercial tissue engineering applications.

Similar content being viewed by others

References

Zhou X, Feng Y, Zhang J, Shi Y, Wang L (2020) Recent advances in additive manufacturing technology for bone tissue engineering scaffolds. Int J Adv Manuf Technol 108(11–12):3591–3606. https://doi.org/10.1007/s00170-020-05444-1

Bagde AD, Kuthe AM, Quazi S, Gupta V, Jaiswal S, Jyothilal S, Lande N, Nagdeve S (2019) State of the art technology for bone tissue engineering and drug delivery. Irbm 40(3):133–144. https://doi.org/10.1016/j.irbm.2019.03.001

Kang CW, Fang FZ (2018) State of the art of bioimplants manufacturing: part I. Adv Manuf 6(1):20–40. https://doi.org/10.1007/s40436-017-0207-4

Loh QL, Choong C (2013) Three-dimensional scaffolds for tissue engineering applications: role of porosity and pore size. Tissue Eng Part B Rev 19(6):485-. https://doi.org/10.1089/TEN.TEB.2012.0437

Borkar T, Goenka V, Jaiswal AK (2021) Application of poly-ε-caprolactone in extrusion-based bioprinting. Bioprinting. 21:e00111-e. https://doi.org/10.1016/J.BPRINT.2020.E00111

Kundu J, Shim J-H, Jang J, Kim S-W, Cho D-W (2015) An additive manufacturing-based PCL–alginate–chondrocyte bioprinted scaffold for cartilage tissue engineering. J Tissue Eng Regen Med 9(11):1286–1297. https://doi.org/10.1002/TERM.1682

Alagoz AS, Hasirci V (2019) 3D printing of polymeric tissue engineering scaffolds using open-source fused deposition modeling. Emergent Mater. https://doi.org/10.1007/s42247-019-00048-2

Cao T, Ho KH, Teoh SH (2003) Scaffold design and in vitro study of osteochondral coculture in a three-dimensional porous polycaprolactone scaffold fabricated by fused deposition modeling. Tissue Eng. 9(SUPPL. 1). https://doi.org/10.1089/10763270360697012

Shor L, Güçeri S, Wen X, Gandhi M, Sun W (2007) Fabrication of three-dimensional polycaprolactone/hydroxyapatite tissue scaffolds and osteoblast-scaffold interactions in vitro. Biomaterials 28(35):5291–5297. https://doi.org/10.1016/J.BIOMATERIALS.2007.08.018

Kim JY, Park EK, Kim S-Y, Shin J-W, Cho D-W (2008) Fabrication of a SFF-based three-dimensional scaffold using a precision deposition system in tissue engineering. J Micromech Microeng 18(5):055027-. https://doi.org/10.1088/0960-1317/18/5/055027

Gonçalves EM, Oliveira FJ, Silva RF, Neto MA, Fernandes MH, Amaral M, Vallet-Regí M, Vila M (2016) Three-dimensional printed PCL-hydroxyapatite scaffolds filled with CNTs for bone cell growth stimulation. J Biomed Mater Res B Appl Biomater 104(6):1210–1219. https://doi.org/10.1002/jbm.b.33432

Heo SJ, Kim SE, Wei J, Hyun YT, Yun HS, Kim DH, Shin JW, Shin JW (2009) Fabrication and characterization of novel nano- and micro-HA/PCL composite scaffolds using a modified rapid prototyping process. J Biomed Mater Res A 89(1):108–116. https://doi.org/10.1002/jbm.a.31726

Patrício T, Domingos M, Gloria A, D’Amora U, Coelho JF, Bártolo PJ (2014) Fabrication and characterisation of PCL and PCL/PLA scaffolds for tissue engineering. Rapid Prototyp J 20(2):145–156. https://doi.org/10.1108/RPJ-04-2012-0037

Kolan KCR, Li W, Semon JA, Day DE, Althage R, Leu M (2018) Solvent and melt based extrusion 3D printing of polycaprolactone bioactive glass composite for tissue engineering. Proceedings of the 3rd International Conference on Progress in Additive Manufacturing, Singapore 176–82. https://doi.org/10.25341/D4B018

Zimmerling A, Yazdanpanah Z, Cooper DML, Johnston JD, Chen X (2021) 3D printing PCL/nHA bone scaffolds: exploring the influence of material synthesis techniques. Biomater Res 25(1):1–12. https://doi.org/10.1186/S40824-021-00204-Y/TABLES/3

Andrea RC, Sinha R, Harings J, Bernaerts KV, Mota C, Moroni L (2021) Additive manufacturing using melt extruded thermoplastics for tissue engineering. Methods Mol Biol 2147:75–99. https://doi.org/10.1007/978-1-0716-0611-7_7

Marchewka J, Laska J (2020) Processing of poly-l-lactide and poly(l-lactide-co-trimethylene carbonate) blends by fused filament fabrication and fused granulate fabrication using RepRap 3D printer. Int J Adv Manuf Technol 106(11–12):4933–4944. https://doi.org/10.1007/s00170-020-04981-z

Moiduddin K, Mian SH, Alkhalefah H, Umer U (2019) Decision advisor based on uncertainty theories for the selection of rapid prototyping system. J Intell Fuzzy Syst 37(3):3897–3923. https://doi.org/10.3233/JIFS-190128

Yeh CC, Chen YF (2018) Critical success factors for adoption of 3D printing. Technol Forecast Soc Change 132(January):209–216. https://doi.org/10.1016/j.techfore.2018.02.003

Justino Netto JM, Ragoni IG, Frezzatto Santos LE, Silveira ZC (2019) Selecting low-cost 3D printers using the AHP method: a case study. SN Appl Sci 1(4). https://doi.org/10.1007/s42452-019-0352-4

Roy MK, Ray A, Pradhan BB (2014) Non-traditional machining process selection using integrated fuzzy AHP and QFD techniques: a customer perspective. Prod Manuf Res 2(1):530–549. https://doi.org/10.1080/21693277.2014.938276

Liu W, Zhu Z, Ye S (2020) A decision-making methodology integrated in product design for additive manufacturing process selection. Rapid Prototyp J 26(5):895–909. https://doi.org/10.1108/RPJ-06-2019-0174

Anand MB, Vinodh S (2016) Application of Fuzzy AHP – TOPSIS for ranking additive manufacturing process for microfabrication. Rapid Prototyp J 24(2):424–435. https://doi.org/10.1108/RPJ-10-2016-0160

Önüt S, Kara SS, Efendigil T (2008) A hybrid fuzzy MCDM approach to machine tool selection. J Intell Manuf 19(4):443–453. https://doi.org/10.1007/s10845-008-0095-3

Chen TCT, Lin YC (2021) Diverse three-dimensional printing capacity planning for manufacturers. Robot Comput Integr Manuf. 67(August). https://doi.org/10.1016/j.rcim.2020.102052

Izadifar Z, Chang T, Kulyk W, Chen X, Eames BF (2016) Analyzing biological performance of 3D-printed, cell-impregnated hybrid constructs for cartilage tissue engineering. Tissue Eng Part C Methods 22(3):173–188. https://doi.org/10.1089/ten.tec.2015.0307

Liu H, Ahlinder A, Yassin MA, Finne-Wistrand A, Gasser TC (2020) Computational and experimental characterization of 3D-printed PCL structures toward the design of soft biological tissue scaffolds. Mater Des 188:108488-. https://doi.org/10.1016/J.MATDES.2020.108488

Shim J-H, Kim JY, Park M, Park J, Cho D-W (2011) Development of a hybrid scaffold with synthetic biomaterials and hydrogel using solid freeform fabrication technology. Biofabrication 3(3):034102-. https://doi.org/10.1088/1758-5082/3/3/034102

Yu YZ, Zheng LL, Chen HP, Chen WH, Hu QX (2014) Fabrication of hierarchical polycaprolactone/gel scaffolds via combined 3D bioprinting and electrospinning for tissue engineering. Adv Manuf 2(3):231–238. https://doi.org/10.1007/s40436-014-0081-2

Ahn S, Kim Y, Lee H, Kim G (2012) A new hybrid scaffold constructed of solid freeform-fabricated PCL struts and collagen struts for bone tissue regeneration: fabrication, mechanical properties, and cellular activity. J Mater Chem 22(31). https://doi.org/10.1039/c2jm33310d

Kim G, Son J, Park S, Kim W (2008) Hybrid process for fabricating 3D hierarchical scaffolds combining rapid prototyping and electrospinning. Macromol Rapid Commun 29(19):1577–1581. https://doi.org/10.1002/marc.200800277

Kim JY, Lee TJ, Cho DW, Kim BS (2010) Solid free-form fabrication-based PCL/HA scaffolds fabricated with a multi-head deposition system for bone tissue engineering. J Biomater Sci Polym Ed 21(6–7):951–962. https://doi.org/10.1163/156856209X458380

Schipani R, Nolan DR, Lally C, Kelly DJ (2020) Integrating finite element modelling and 3D printing to engineer biomimetic polymeric scaffolds for tissue engineering. Connect Tissue Res 61(2):174–189. https://doi.org/10.1080/03008207.2019.1656720

Choi JW, Lee K, Koh YH, Kim HE (2020) Novel poly(ε-caprolactone) scaffolds comprised of tailored core/shell-structured filaments using 3D plotting technique. Mater Lett 269:127659-. https://doi.org/10.1016/J.MATLET.2020.127659

Beatrice CAG, Shimomura KMB, Backes EH, Harb SV, Costa LC, Passador FR, Pessan LA (2021) Engineering printable composites of poly (ε-polycaprolactone) / β-tricalcium phosphate for biomedical applications. Polym Compos 42(3):1198–1213. https://doi.org/10.1002/pc.25893

Dávila JL, Freitas MS, Inforçatti Neto P, Silveira ZC, Silva JVL, D’Ávila MA (2016) Fabrication of PCL/β-TCP scaffolds by 3D mini-screw extrusion printing. J Appl Polym Sci 133(15):1–9. https://doi.org/10.1002/app.43031

Aydogdu MO, Mutlu B, Kurt M, Inan AT, Kuruca SE, Erdemir G, Sahin YM, Ekren N, Oktar FN (2019) Gunduz O (2019) Developments of 3D polycaprolactone/beta-tricalcium phosphate/collagen scaffolds for hard tissue engineering. J Aust Ceram Soc 55(3):849–855. https://doi.org/10.1007/S41779-018-00299-Y

Albrecht LD, Sawyer SW, Soman P (2016) Developing 3D scaffolds in the field of tissue engineering to treat complex bone defects. 3D Print Addit Manuf 3(2):106–112. https://doi.org/10.1089/3DP.2016.0006

Hutmacher DW, Schantz T, Zein I, Ng KW, Teoh SH, Tan KC (2001) Mechanical properties and cell cultural response of polycaprolactone scaffolds designed and fabricated via fused deposition modeling. J Biomed Mater Res 55(2):203–216. https://doi.org/10.1002/1097-4636(200105)55:2%3c203::AID-JBM1007%3e3.0.CO;2-7

Liu F, Vyas C, Poologasundarampillai G, Pape I, Hinduja S, Mirihanage W, Bartolo PJ (2018) Process-driven microstructure control in melt-extrusion-based 3D printing for tailorable mechanical properties in a polycaprolactone filament. Macromol Mater Eng 303(8):1800173-. https://doi.org/10.1002/MAME.201800173

Justino Netto JM, Idogava HT, Frezzatto Santos LE, Silveira Z, d C, Romio P, Alves J L, (2021) Screw-assisted 3D printing with granulated materials: a systematic review. Int J Adv Manuf Technol 115(9–10):2711–2727. https://doi.org/10.1007/s00170-021-07365-z

Jo S, Kang SM, Park SA, Kim WD, Kwak J, Lee H (2013) Enhanced adhesion of preosteoblasts inside 3D PCL scaffolds by polydopamine coating and mineralization. Macromol Biosci 13(10):1389–1395. https://doi.org/10.1002/MABI.201300203

Declercq HA, Desmet T, Dubruel P, Cornelissen MJ (2014) The role of scaffold architecture and composition on the bone formation by adipose-derived stem cells. Tissue Eng Part A 20(1–2):434–444. https://doi.org/10.1089/ten.tea.2013.0179

Yong LC, Malek NFA, Yong ENS, Yap WH, Nobuyuki M, Yoshitaka N (2019) Fabrication of hydroxyapatite blended cyclic type polylactic acid and poly (ε-caprolactone) tissue engineering scaffold. Int J Appl Ceram Technol 16(2):455–461. https://doi.org/10.1111/IJAC.13115

Kim JY, Jin G-Z, Park IS, Kim J-N, Chun SY, Park EK, Kim S-Y, Yoo J, Kim S-H, Rhie J-W, Cho D-W (2010) Evaluation of solid free-form fabrication-based scaffolds seeded with osteoblasts and human umbilical vein endothelial cells for use in vivo osteogenesis. Tissue Eng Part A 16(7):2229–2236. https://doi.org/10.1089/TEN.TEA.2009.0644

Murphy C, Kolan K, Li W, Semon J, Day D, Leu M (2017) 3D bioprinting of stem cells and polymer/bioactive glass composite scaffolds for bone tissue engineering. Int J Bioprint 3(1):53–63. https://doi.org/10.18063/IJB.2017.01.005

Siddiqui N, Asawa S, Birru B, Baadhe R (2018) Rao S (2018) PCL-based composite scaffold matrices for tissue engineering applications. Mol Biotechnol 60(7):506–532. https://doi.org/10.1007/S12033-018-0084-5

Cubo-Mateo N, Rodríguez-Lorenzo LM (2020) Design of thermoplastic 3D-printed scaffolds for bone tissue engineering: influence of parameters of “Hidden” importance in the physical properties of scaffolds. Polymers (Basel) 12(7):1546

Luo W, Zhang S, Lan Y, Huang C, Wang C, Lai X, Chen H, Ao N (2018) 3D printed porous polycaprolactone/oyster shell powder (PCL/OSP) scaffolds for bone tissue engineering. Mater Res Express 5(4):045403. https://doi.org/10.1088/2053-1591/AAB916

Hou Y, Wang W, Bártolo P (2020) Novel poly(ɛ-caprolactone)/graphene scaffolds for bone cancer treatment and bone regeneration. 3D Print Addit Manuf 7(5):222–229. https://doi.org/10.1089/3DP.2020.0051

Huang B, Vyas C, Roberts I, Poutrel QA, Chiang WH, Blaker JJ, Huang Z, Bártolo P (2019) Fabrication and characterisation of 3D printed MWCNT composite porous scaffolds for bone regeneration. Mater Sci Eng C 98:266–278. https://doi.org/10.1016/j.msec.2018.12.100

Jiang CP, Huang JR, Hsieh MF (2011) Fabrication of synthesized PCL-PEG-PCL tissue engineering scaffolds using an air pressure-aided deposition system. Rapid Prototyp J 17(4):288–297. https://doi.org/10.1108/13552541111138414

Buyuksungur S, Hasirci V, Hasirci N (2021) 3D printed hybrid bone constructs of PCL and dental pulp stem cells loaded GelMA. J Biomed Mater Res A 109(12):2425–2437. https://doi.org/10.1002/jbm.a.37235

Kim YB, Lee H, Yang GH, Choi CH, Lee D, Hwang H, Jung WK, Yoon H, Kim GH (2016) Mechanically reinforced cell-laden scaffolds formed using alginate-based bioink printed onto the surface of a PCL/alginate mesh structure for regeneration of hard tissue. J Colloid Interface Sci 461:359–368. https://doi.org/10.1016/j.jcis.2015.09.044

Li Y, Yu Z, Ai F, Wu C, Zhou K, Cao C, Li W (2021) Characterization and evaluation of polycaprolactone/hydroxyapatite composite scaffolds with extra surface morphology by cryogenic printing for bone tissue engineering. Mater Des 205:109712. https://doi.org/10.1016/j.matdes.2021.109712

Kolan KCR, Semon JA, Bromet B, Day D, Leu MC (2019) Bioprinting with human stem cell-laden alginate-gelatin bioink and bioactive glass for tissue engineering. Int J Bioprint 5(2.2 Special Issue):3–15. https://doi.org/10.18063/ijb.v5i2.2.204

Peko I, BajiĆ D, VeŽA I (2015) Selection of additive manufacturing process using the AHP method. International conference: mechanical technologies and structural materials (2018):119–129. https://doi.org/10.13140/RG.2.1.2713.2246

Wang Y, Zhong RY, Xu X (2018) A decision support system for additive manufacturing process selection using a hybrid multiple criteria decision-making method. Rapid Prototyp J 24(9):1544–1553. https://doi.org/10.1108/RPJ-01-2018-0002

Chen TCT, Lin YC (2020) A FAHP-FTOPSIS approach for bioprinter selection. Health Technol (Berl) 10(6):1455–1467. https://doi.org/10.1007/s12553-020-00469-8

Mohamed OA, Masood SH, Bhowmik JL (2015) Optimization of fused deposition modeling process parameters: a review of current research and future prospects. Adv Manuf 3(1):42–53. https://doi.org/10.1007/s40436-014-0097-7

Cai S, Wu C, Yang W, Liang W, Yu H, Liu L (2020) Recent advance in surface modification for regulating cell adhesion and behaviors. Nanotechnol Rev 9(1):971–989. https://doi.org/10.1515/ntrev-2020-0076

Anselme K, Ploux L, Ponche A (2010) Cell/material interfaces: Influence of surface chemistry and surface topography on cell adhesion. J Adhes Sci Technol 24(5):831–852. https://doi.org/10.1163/016942409X12598231568186

Zhou J, Zhang X, Sun J, Dang Z, Li J, Li X, Chen T (2018) The effects of surface topography of nanostructure arrays on cell adhesion. Phys Chem Chem Phys 20(35):22946–22951. https://doi.org/10.1039/C8CP03538E

Patrício T, Domingos M, Gloria A, Bártolo P (2013) Characterisation of PCL and PCL/PLA scaffolds for tissue engineering. Procedia CIRP 5:110–114. https://doi.org/10.1016/j.procir.2013.01.022

Vogt L, Rivera LR, Liverani L, Piegat A, El Fray M, Boccaccini AR (2019) Poly(epsilon-caprolactone)/poly(glycerol sebacate) electrospun scaffolds for cardiac tissue engineering using benign solvents. Mater Sci Eng C Mater Biol Appl 103:109712. https://doi.org/10.1016/j.msec.2019.04.091

Çentinkaya C, Kabak M, Özceylan E (2017) 3D printer selection by using fuzzy analytic hierarchy process and PROMETHEE. Bilişim Teknolojileri Dergisi 371–380. https://doi.org/10.17671/gazibtd.347610

Prabhu SR, Ilangkumaran M (2019) Selection of 3D printer based on FAHP integrated with GRA-TOPSIS. Int J Mater Prod Technol 58(2–3):155–177. https://doi.org/10.1504/IJMPT.2019.097667

Kadkhoda-Ahmadi S, Hassan A, Asadollahi-Yazdi E (2019) Process and resource selection methodology in design for additive manufacturing. Int J Adv Manuf Technol 104(5–8):2013–2029. https://doi.org/10.1007/s00170-019-03991-w

Chang TH, Wang TC (2009) Using the fuzzy multi-criteria decision making approach for measuring the possibility of successful knowledge management. Inf Sci 179(4):355–370. https://doi.org/10.1016/j.ins.2008.10.012

Saaty RW (1987) The analytic hierarchy process-what it is and how it is used. Math Model 9(3–5):161–176. https://doi.org/10.1016/0270-0255(87)90473-8

Acknowledgements

The authors gratefully acknowledge the efforts of experts and users for their assessments.

Funding

This research is funded by the Vingroup Innovation Foundation (VINIF) through project VINIF.2020.DA13.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study’s conception and design. Lan Xuan Phung created the research direction, designed the methodology, reviewed the related works, and fabricated the expert system. Truong Do performed and collected the experts’ judgments. Phuong Tran evaluated the methodology and system. Trung Kien Nguyen created the model’s structure and made data analysis. All authors revised and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Phung, L.X., Do, T., Tran, P. et al. Development of a fuzzy-AHP system to select the printing method for polycaprolactone (PCL)-based scaffolds. Int J Adv Manuf Technol 121, 5971–5990 (2022). https://doi.org/10.1007/s00170-022-09655-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09655-6