Abstract

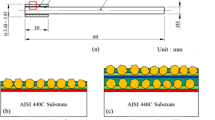

Electroplated diamond tools with single-layered high density diamond particles in an average size of 150 μm were prepared through a three-step electroplating process, including Ni-undercoating, Ni-diamond co-electrodeposition, and Cr-C strengthening electroplating. Martensitic stainless steel (AISI 440C) rods with a diameter of 3 mm were used as substrates for tool fabrications. To evaluate tool grinding performances, linear slot grinding tests on the Al2O3 plates were conducted. The grinding performance of an electroplated diamond tool was determined through its maximum ground length upon tool failure. Experimental results show that an electroplated diamond tool with high density of diamond particles can be prepared by using Ni-diamond co-electrodeposition. After annealing at 500 °C for 30 min, the hardness of Cr-C deposit was significantly increased from 597 to 1636 Hv. The anneal-hardened Cr-C deposit is a suitable strengthening layer for fabricating electroplated diamond tools. The grinding performance of an electroplated diamond tool was strongly affected by the Ni-undercoating thickness. The highest maximum ground length of 2231 mm can be achieved by the electroplated diamond tool with a Ni-undercoating thickness of 90 μm. When the Cr-C strengthening deposit wore out, extruded diamond particles on the tool surface could be easily embedded into the Ni-undercoating, leading to fatigue fracture of the AISI 440C substrate.

Similar content being viewed by others

Availability of data and material

Not applicable.

Code availability

Not applicable.

References

Gupta RK, Pratap B (2021) Diamond tools processing for marble and granite: cutting & wear. Mater Today Proc 46:2135–2140. https://doi.org/10.1016/j.matpr.2021.02.346

Zhang H, Zhang J, Wang Z et al (2016) A new frame saw machine by diamond segmented blade for cutting granite. Diam Relat Mater 69:40–48. https://doi.org/10.1016/j.diamond.2016.07.003

Wang X, Chou CC, Lee JW et al (2020) Preparation and investigation of diamond-incorporated copper coatings on a brass substrate by composite electrodeposition. Surf Coatings Technol 386:125508. https://doi.org/10.1016/j.surfcoat.2020.125508

Huang CA, Yang SW, Shen CH et al (2019) Fabrication and evaluation of electroplated Ni–diamond and Ni–B–diamond milling tools with a high density of diamond particles. Int J Adv Manuf Technol 104:2981–2989. https://doi.org/10.1007/s00170-019-04174-3

Zhou H, Zhu L, Qian Z et al (2014) Codeposition process of Ni-diamond. Rare Met Mater Eng 43:2177–2181

Li S, Gao YF (2020) Effect of abrasive density on sawing performance of electroplated diamond wire. Manuf Technol Mech Tool 6:104–107

Lee EC, Moon IT (2002) Electrolytic codeposition of diamond particles with nickel and cobalt metals. Plat Surf Finish

Deja M, Zieliński D (2020) Wear of electroplated diamond tools in lap-grinding of Al2O3 ceramic materials. Wear 460–461:203461. https://doi.org/10.1016/j.wear.2020.203461

Shi Z, Malkin S (2006) Wear of electroplated CBN grinding wheels. J Manuf Sci Eng Trans ASME 128:110–118. https://doi.org/10.1115/1.2122987

Wu Y, Luo J, Wang Y et al (2019) Critical effect and enhanced thermal conductivity of Cu-diamond composites reinforced with various diamond prepared by composite electroplating. Ceram Int 45:13225–13234. https://doi.org/10.1016/j.ceramint.2019.04.008

Chen TJ, Chiou YC, Lee RT (2009) Grinding characteristics of diamond film using composite electro-plating in-process sharpening method. Int J Mach Tools Manuf 49:470–477. https://doi.org/10.1016/j.ijmachtools.2009.01.002

Ko TJ, Yoon IJ (2012) Mill-grinding with electroplated diamond abrasives for ceramic cutting. Int J Precis Eng Manuf 13:5–10. https://doi.org/10.1007/s12541-012-0001-y

Liang G, Zhou X, Zhao F (2016) The grinding surface characteristics and evaluation of particle-reinforced aluminum silicon carbide. Sci Eng Compos Mater 23(6):671–676. https://doi.org/10.1515/secm-2014-0377

Liang ZQ, Du YC, Ma Y et al (2022) Development of polycrystalline diamond micro end mill for milling-grinding combined machining of cemented carbide. J Manuf Process 79:844–853. https://doi.org/10.1016/j.jmapro.2022.05.020

Huang CA, Shen CH, Yang SW et al (2020) Fabrication and evaluation of electroplated diamond grinding rods strengthened with Cr-C deposit. Int J Adv Manuf Technol 110:2541–2550. https://doi.org/10.1007/s00170-020-05989-1

Huang CA, Liu YW, Yu C, Yang CC (2011) Role of carbon in the chromium deposit electroplated from a trivalent chromium-based bath. Surf Coatings Technol 205:3461–3466. https://doi.org/10.1016/j.surfcoat.2010.12.010

Huang CA, Yang SW, Liu YW, Lai PL (2019) Effect of Cu and Ni undercoatings on the electrochemical corrosion behaviour of Cr-C-coated steel samples in 0.1 M H2SO4 solution with 1 g/L NaCl. Coatings 9:531. https://doi.org/10.3390/coatings9090531

Choudhary A, Paul S (2020) The wear mechanisms of diamond grits in grinding of alumina and yttria-stabilized zirconia under different cooling-lubrication schemes. Wear. https://doi.org/10.1016/j.wear.2020.203315

Huang CA, Chen JY, Chuang CH, Mayer J (2017) Properties of Cr–C–Al2O3 deposits prepared on a Cu substrate using Cr3+-based plating baths. Powder Metall Met Ceram 55:596–602. https://doi.org/10.1007/s11106-017-9844-1

Funding

This work was supported by Chang Gung Medical Foundation in Taiwan [Grant numbers: CMRPD2L0091]. The grant was awarded to Dr. Ching An Huang.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Huang, C.A., Shen, C.H., Huang, W.Z. et al. Grinding performance of electroplated diamond tools strengthened with Cr-C deposit using D-150 diamond particles. Int J Adv Manuf Technol 121, 4549–4558 (2022). https://doi.org/10.1007/s00170-022-09604-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09604-3