Abstract

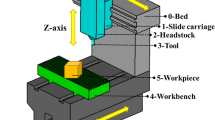

Due to the complex structure and diverse functions of the CNC machine tool, there may be structural interactions between contemporaneous meta-action (CMA), which will lead to reliability coupling of the CMA. And these coupling relationships have a great influence on the reliability comprehensive evaluation of the CNC machine tool. Therefore, in order to analyze the reliability coupling mechanism of T-rotation-type CMA, based on the meta-action theory, this paper first introduces the corresponding concepts vis-à-vis CMA and analyzes the reliability coupling reasons of T-rotation-type CMA. Then, the bearing models, stiffness models, and dynamic models of gear 1 rotation meta-action unit under frame offset and frame deflection are established. What’s more, the interval theory is utilized to construct the reliability coupling model of T-rotation-type CMA. Finally, by comparison and simulation analyses, the rationality and effectiveness of the proposed stiffness model and reliability model are verified, and the reliability coupling mechanism of T-rotation-type CMA under frame deformation is analyzed.

Similar content being viewed by others

Abbreviations

- △x, △y :

-

Frame offset distance (mm)

- G ijH, G oj 1 (H = 1, 2):

-

Friction forces of the jth ball with the inner-and outer-race (N)

- d H (H = 1,2) :

-

Relative displacement vector of inner and outer rings under frame offset or frame deflection (mm)

- △r, △z, △φ :

-

Radial runout error, end face runout error, angular swing error (mm, mrad)

- δ xH, δ yH, δ zH (H = 1, 2):

-

Relative displacements of inner and outer rings along X, Y, and Z directions (mm)

- α ijH, α ojH (H = 1, 2):

-

Actual contact angles between jth ball with the inner-and outer-race (rad)

- θ xH, θ yH (H = 1, 2):

-

Relative angular displacements of the inner and outer rings around the X-axis and Y-axis (mrad)

- δ ijH, δ ojH (H = 1, 2):

-

Contact deformation between jth ball with the inner-and outer-race (mm)

- F H (H = 1,2):

-

Static load vector under frame offset or frame deflection (N)

- A 1 jH, A 2 jH, X 1 jH, X 2 jH (H = 1, 2):

-

Intermediate variables introduced to simplify the calculation (mm)

- F xH, F yH, F ZH (H = 1, 2):

-

Static loads along X, Y, and Z directions (N)

- λ ij, λ oj :

-

Friction constants at the jth ball

- M xH, M yH (H = 1, 2):

-

Static moment loads with respect to X-axis and Y-axis (N·mm/rad)

- \({\overline{\text{F}}}_{\text{xH}}\text{,}{ \, \overline{\text{F}}}_{\text{yH}}\) (H = 1, 2):

-

The time-varying components of external forces caused by the unbalanced force (N)

- Α :

-

Unloaded contact angle (°)

- x, y, z, φ x, φ y :

-

Displacements of gear 1 (mm/rad)

- A 0 :

-

Distance between curvature centers of inner and outer races before frame deformation

- \({\overline{\text{M}}}_{\text{xH}}\text{,}{\overline{\text{M}}}_{\text{yH}}\) (H = 1, 2):

-

The time-varying components of external moments caused by the unbalanced force (N·mm/rad)

- R i, R o :

-

Radii of locus of inner and outer race groove curvature centers (mm)

- \({\text{c}}_{\text{xx}}\text{, }{\text{c}}_{\text{yy}}\text{,}{ \, {\text{c}}}_{\text{zz}}\text{,}{\text{ c}}_{{\varphi }_{\text{x}}{\varphi }_{\text{x}}}\text{, }{\text{c}}_{{\varphi }_{\text{y}}{\varphi }_{\text{y}}}\) :

-

Damping coefficients of the gear 1 rotation meta-action unit (N s/m)

- r i, r o :

-

Radii of inner and outer ring groove (mm)

- \({\text{k}}_{\text{xxH}}^{^{\prime}}\text{, }{\text{k}}_{\text{yyH}}^{^{\prime}}\text{,}{\text{ k}}_{\text{zzH}}^{^{\prime}}\text{, }{\text{k}}_{{\varphi }_{\text{x}}{\varphi }_{\text{x}}H}^{^{\prime}}\text{,}{\text{ k}}_{{\varphi }_{\text{y}}{\varphi }_{\text{y}}H}^{^{\prime}}\) (H = 1, 2):

-

Support stiffness coefficients of bearing (KN/mm, MN·mm/rad)

- ѱ j :

-

Azimuth angle of rolling element (rad)

- \({\overline{\alpha }}_{0}{\overline{D} }_{0}{\overline{A} }_{00}{\overline{e} }_{0}{\overline{d} }_{m0}\) :

-

Design values of geometric parameters

- ω c, ω s :

-

Angular speeds of cage and shaft (rad/s)

- M gjH (H = 1, 2):

-

Gyroscopic moment of the jth ball (N·mm/rad)

- Z :

-

Rolling element number

- η :

-

The uncertainty of geometric parameters

- D :

-

Diameter of rolling element (mm)

- \(\phi\) :

-

Geometric parameter vector

- K :

-

Hertzian contact coefficient

- \({\alpha }_{0}^{I}{D}_{0}^{I}{A}_{00}^{I}{e}_{0}^{I}{d}_{m0}^{I}\) :

-

Interval values of geometric parameters

- e :

-

Eccentricity of the gear 1 rotation meta-action unit (mm)

- I d, I p :

-

Diametral moment of inertia and polar moment of inertia (kg·m2)

- L :

-

Half the shaft length (mm)

- \({\overline{T} }_{x}\left(t\right)\), \({T}_{x}\left(t\right)\) :

-

Expected vibration displacement and actual vibration displacement in the X direction (mm)

- d m :

-

Diameter of the pitch circle of the bearing (mm)

- g x(\(\phi\), t(θ x,θ y)), g x(\(\phi\) ,t(△x, △y)):

-

Limit state function under frame offset or frame deflection

- m :

-

Rotor mass (kg)

- \({R}_{x}\left(t\right),{R}_{y}\left(t\right),{R}_{z}\left(t\right),{R}_{{\varphi }_{x}}\left(t\right),{R}_{{\varphi }_{y}}\left(t\right)\) :

-

Reliability functions of different vibration responses

- F cjH (H = 1, 2):

-

Centrifugal force of the jth ball (N)

- R(t) :

-

Reliability of the gear 1 rotation meta-action unit

- P ijH, P ojH (H = 1, 2):

-

Contact forces of the jth ball with the inner-and outer-race (N)

References

Wang R, Gao X, Gao Z, Li S, Gao J, Xu J, Deng W (2020) Comprehensive reliability evaluation of multistate complex electromechanical systems based on similarity of cloud models. Qual Reliab Eng Int 36:1048–1073. https://doi.org/10.1002/qre.2614

Wang P, Wang H, Chen X (2019) Research on reliability comprehensive evaluation method of five-axis CNC machine tools based on AHP and extension theory. Journal of Engineering-Joe 2019:8599–8603. https://doi.org/10.1049/joe.2018.9064

Jin C, Ran Y, Wang Z, Zhang G (2021) Prioritization of key quality characteristics with the three-dimensional HoQ model-based interval-valued spherical fuzzy-ORESTE method. Eng Appl Artif Intell 104. https://doi.org/10.1016/j.engappai.2021.104271

Jin CX, Ran Y, Wang ZC, Huang GQ, Xiao LM, Zhang GB (2020) Reliability analysis of gear rotation meta-action unit based on Weibull and inverse Gaussian competing failure process. Eng Fail Anal 117:16. https://doi.org/10.1016/j.engfailanal.2020.104953

Yu H, Zhang G, Ran Y (2019) A more reasonable definition of failure mode for mechanical systems using meta-action. IEEE Access 7:4898–4904. https://doi.org/10.1109/access.2018.2888542

Li Y, Zhang X, Ran Y, Zhang W, Zhang G (2019) Reliability and modal analysis of key meta-action unit for CNC machine tool. IEEE Access 7:23640–23655. https://doi.org/10.1109/ACCESS.2019.2899623

Ren X, Zhai J, Ren G (2017) Calculation of radial load distribution on ball and roller bearings with positive, negative and zero clearance. Int J Mech Sci 131:1–7. https://doi.org/10.1016/j.ijmecsci.2017.06.042

Deng SE, Dong X, Cui YC, Hu GC (2015) Analysis of dynamic stiffness characteristics of double-row angular contact ball bearings. Binggong Xuebao/Acta Armamentarii 36:1140–1146. https://doi.org/10.3969/j.issn.1000-1093.2015.06.026

Tomovic R (2012) Calculation of the boundary values of rolling bearing deflection in relation to the number of active rolling elements. Mech Mach Theory 47:74–88. https://doi.org/10.1016/j.mechmachtheory.2011.08.006

Luo Y, Jia H, Wang C, Wang P, Xu H (2019) Effect of rolling bearing on dynamic characteristics of seal-rotor system, in: 10th IEEE Prognostics and System Health Management Conference (PHM-Qingdao), Qingdao, PEOPLES R CHINA, 2019.

Lin S, Jiang S (2019) Dynamic characteristics of motorized spindle with tandem duplex angular contact ball bearings. J Vib Acoust-Trans ASME 141.https://doi.org/10.1115/1.4044300

Tong V-C, Hong S-W (2018) Vibration analysis of flexible rotor with angular contact ball bearings using a general bearing stiffness model, Journal of the Korean Society for. Precis Eng 35:1179–1189

Liu Y, Zhang Z (2022) Parameters research on time-varying stiffness of the ball bearing system without race control hypothesis. Proc Inst Mech Eng Part C-J Eng Mech Eng Sci 236:1334–1351.https://doi.org/10.1177/09544062211017955

Cheng H, Zhang Y, Lu W, Yang Z (2021) Effect of boundary position and defect shape on the mechanical properties of ball bearings. Mech Based Des Struct Mach. https://doi.org/10.1080/15397734.2021.1875329

Fang B, Zhang J, Yan K, Hong J, Wang MY (2019) A comprehensive study on the speed-varying stiffness of ball bearing under different load conditions. Mech Mach Theory 136:1–13. https://doi.org/10.1016/j.mechmachtheory.2019.02.012

Li X, Yu K, Ma H, Cao L, Luo Z, Li H, Che L (2018) Analysis of varying contact angles and load distributions in defective angular contact ball bearing. Eng Fail Anal 91:449–464. https://doi.org/10.1016/j.engfailanal.2018.04.050

Xu TF, Yang LH, Wu W, Wang K (2021) Effect of angular misalignment of inner ring on the contact characteristics and stiffness coefficients of duplex angular contact ball bearings. Mech Mach Theory 157:22. https://doi.org/10.1016/j.mechmachtheory.2020.104178

Xu TF, Yang LH, Wang K (2020) Characteristics of duplex angular contact ball bearing with combined external loads and angular misalignment. Appl Sci Basel 10:25.https://doi.org/10.3390/app10175756

Yang Z, Chen H, Yu T (2017) Effects of rolling bearing configuration on stiffness of machine tool spindle. Proc Inst Mech Eng C J Mech Eng Sci 232:775–785. https://doi.org/10.1177/0954406217693659

Fang B, Yan K, Hong J, Zhang J (2021) A comprehensive study on the off-diagonal coupling elements in the stiffness matrix of the angular contact ball bearing and their influence on the dynamic characteristics of the rotor system. Mech Mach Theory 158.https://doi.org/10.1016/j.mechmachtheory.2021.104251

Zhang Y, Fang B, Kong L, Li Y (2020) Effect of the ring misalignment on the service characteristics of ball bearing and rotor system. Mech Mach Theory 151.https://doi.org/10.1016/j.mechmachtheory.2020.103889

Cao H, Shi F, Li Y, Li B, Chen X (2019) Vibration and stability analysis of rotor-bearing-pedestal system due to clearance fit. Mech Syst Signal Proc 133.https://doi.org/10.1016/j.ymssp.2019.106275

Liu H, Zhang Y, Li C, Li Z (2021) Nonlinear dynamic analysis of CNC lathe spindle-bearing system considering thermal effect. Nonlinear Dyn 105:131–166. https://doi.org/10.1007/s11071-021-06613-x

Zhang Y, Zhang MQ, Xie LY, Zhang K (2021) The effect of the uncertain initial angular misalignment on fatigue life of spindle-bearing system. Forsch Ingwes. Eng Res 85:39–56.https://doi.org/10.1007/s10010-020-00430-1

Zhang Y, Zhang MQ, Wang YW, Xie LY (2020) Fatigue life analysis of ball bearings and a shaft system considering the combined bearing preload and angular misalignment. Appl Sci Basel 10:21.https://doi.org/10.3390/app10082750

Li X, Lv Y, Yan K, Liu J, Hong J (2017) Study on the influence of thermal characteristics of rolling bearings and spindle resulted in condition of improper assembly. Appl Therm Eng 114:221–233. https://doi.org/10.1016/j.applthermaleng.2016.11.194

Yang ZY, Ching JY (2020) A novel reliability-based design method based on quantile-based first-order second-moment. Appl Math Model 88:461–473. https://doi.org/10.1016/j.apm.2020.06.038

Yang ZY, Ching JY (2019) A novel simplified geotechnical reliability analysis method. Appl Math Model 74:337–349. https://doi.org/10.1016/j.apm.2019.04.055

Wang Z, Broccardo M, Song J (2019) Hamiltonian Monte Carlo methods for Subset Simulation in reliability analysis. Struct Saf 76:51–67. https://doi.org/10.1016/j.strusafe.2018.05.005

Liu K, Wu JK, Liu HB, Sun MJ, Wang YQ (2021) Reliability analysis of thermal error model based on DBN and Monte Carlo method. Mech Syst Signal Proc 146:15. https://doi.org/10.1016/j.ymssp.2020.107020

Gao SZ, Zhang SX, Zhang YM, Gao Y (2020) Operational reliability evaluation and prediction of rolling bearing based on isometric mapping and NoCuSa-LSSVM. Reliab Eng Syst Saf 201:11. https://doi.org/10.1016/j.ress.2020.106968

Liu XG, Gu Y, He ST, Xu ZP, Zhang ZY (2019) A robust reliability prediction method using weighted least square support vector machine equipped with chaos modified particle swarm optimization and online correcting strategy. Appl Soft Comput 85:17. https://doi.org/10.1016/j.asoc.2019.105873

Zhang Z, Jiang C, Wang GG, Han X (2015) First and second order approximate reliability analysis methods using evidence theory. Reliab Eng Syst Saf 137:40–49. https://doi.org/10.1016/j.ress.2014.12.011

Zhao W, Chen YY, Liu JK (2020) An effective first order reliability method based on Barzilai-Borwein step. Appl Math Model 77:1545–1563. https://doi.org/10.1016/j.apm.2019.08.026

Aslett LJM, Nagapetyan T, Vollmer SJ (2017) Multilevel Monte Carlo for reliability theory. Reliab Eng Syst Saf 165:188–196. https://doi.org/10.1016/j.ress.2017.03.003

Keshtegar B, Kisi O (2017) M5 model tree and Monte Carlo simulation for efficient structural reliability analysis. Appl Math Model 48:899–910. https://doi.org/10.1016/j.apm.2017.02.047

Qian HM, Li YF, Huang HZ (2020) Time-variant reliability analysis for industrial robot RV reducer under multiple failure modes using Kriging model. Reliab Eng Syst Saf 199:9. https://doi.org/10.1016/j.ress.2020.106936

Pan QJ, Dias D (2017) An efficient reliability method combining adaptive support vector machine and Monte Carlo simulation. Struct Saf 67:85–95. https://doi.org/10.1016/j.strusafe.2017.04.006

Stern RE, Song J, Work DB (2017) Accelerated Monte Carlo system reliability analysis through machine learning-based surrogate models of network connectivity. Reliab Eng Syst Saf 164:1–9. https://doi.org/10.1016/j.ress.2017.01.021

Zhao HL, Yue ZF, Liu YS, Liu W, Gao ZZ (2017) Structural reliability assessment based on low-discrepancy adaptive importance sampling and artificial neural network. Proc Inst Mech Eng Part G-J Aerosp Eng 231:497–509.https://doi.org/10.1177/0954410016640820

Harris TA, Crecelius WJ (1986) Rolling bearing analysis. J Tribol 108:149–150. https://doi.org/10.1115/1.3261135

Zhang XN, Han QK, Peng ZK, Chu FL (2016) A comprehensive dynamic model to investigate the stability problems of the rotor-bearing system due to multiple excitations. Mech Syst Signal Proc 70–71:1171–1192. https://doi.org/10.1016/j.ymssp.2015.10.006

Wu H, Cui G, Chen P, Hou H (2020) Motion reliability evaluation of six-axes robot based on non-probability interval theory. Int J Veh Des 84:238–257

Solovyev SA (2020) Structural reliability analysis based on interval estimation of random variables. Stroitel’naya mekhanika i raschet sooruzhenii 56–61.https://doi.org/10.37538/0039-2383.2020.3.56.61

Li J, Ran Y, Wang HW, Huang GQ, Mu ZY, Zhang GB (2020) Dynamic performance reliability analysis of rolling linear guide under parameter uncertainty. J Mech Sci Technol 34:4525–4536. https://doi.org/10.1007/s12206-020-1012-8

Cheng J, Liu Z, Tang M, Tan J (2017) Robust optimization of uncertain structures based on normalized violation degree of interval constraint. Comput Struct 182:41–54. https://doi.org/10.1016/j.compstruc.2016.10.010

Zhang YF, Fang B, Kong LF, Li Y (2020) Effect of the ring misalignment on the service characteristics of ball bearing and rotor system. Mech Mach Theory 151:16. https://doi.org/10.1016/j.mechmachtheory.2020.103889

Krämer E (1993) Dynamics of Rotors and Foundations

Chi Y, Yang S, Jiao W, He J, Gu X, Papatheou E (2019) Spectral DCS-based feature extraction method for rolling element bearing pseudo-fault in rotor-bearing system. Measurement 132:22–34. https://doi.org/10.1016/j.measurement.2018.09.006

Geng K, Lin S (2019) Effect of angular misalignment on the stiffness of the double-row self-aligning ball bearing. Proc Inst Mech Eng C J Mech Eng Sci 234:946–962. https://doi.org/10.1177/0954406219885979

Funding

This work was financially supported by the National Natural Science Foundation, China (No. 51835001); the Independent Research Project of State Key Laboratory of Mechanical Transmission, China (SKLMT-ZZKT-2021R06).

Author information

Authors and Affiliations

Contributions

Chuanxi Jin compiled the manuscript and studied an engineering example. Genbao Zhang checked the manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jin, C., Zhang, G. Reliability coupling mechanism analyses of T-rotation-type CMA with frame deformation in CNC machine tools. Int J Adv Manuf Technol 124, 4269–4296 (2023). https://doi.org/10.1007/s00170-022-09565-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09565-7