Abstract

RB-SiC ceramic is one of the most important and useful materials as optical precision elements in many scientific research fields. In this paper, a novel cold atmospheric plasma (CAP) process via oxygen (O2), which is based on the precision grinding process in surface technology to modify at room temperature for grinding with a combination of plasma oxidation surface modification, is proposed. To identify the performance of the proposed cold atmospheric plasma process via oxygen method on the surface modification of RB-SiC ceramic fabrication of the precision grinding process, precision grinding test was conducted. To reveal the fundamental issue in the grinding of RB-SiC ceramic, surface-modified layer and mathematical model of the grinding trajectory via the point P(Ai, Aj) model analysis were conducted to investigate the effect of the composite process on grinding force and the mechanism of surface material removal in the presence of plasma oxidation. As a result of the method included the kept constant during the precision grinding of the composite process self-adaption-grinding process to avoid the deviation caused by second grinding particle entry. As a summary, we provide a significant cold atmospheric plasma-precision grinding compound process toward the establishment of the basic theory by analyzing the mechanism of the experimental test design and computation. The process and technical difficulties of RB-SiC ceramic and mechanism of surface modified layer material removal during precision grinding were solved.

Graphical abstract

The single-precision grinding and composite process schematic diagram process of the grinding wheel: (a) Traditional precision grinding process; (b) Cold atmospheric plasma (CAP) via oxygen (O2) based on the precision grinding process.

Similar content being viewed by others

Data availability

No applicable.

Code availability

The concepts of coding were presented with pseudocode in the article; thus, there is no access for the custom code.

Change history

05 September 2022

Springer Nature’s version of this paper was updated to present the correct Abbreviation list.

Abbreviations

- a p :

-

Precision grinding depth, μm

- Δa p :

-

The depth of grinding, μm

- b :

-

The width of precision grinding face, mm

- e s :

-

The grinding force-the grinding specific energy, J/mm3

- dA :

-

The actual contact area during the grinding process, mm2

- D RB-SiC :

-

The diameter of the RB-SiC ceramic, mm

- E RB-SiC :

-

The precision grinding power, W

- f grinding wheel :

-

The tangent and normal of the grinding force, N

- F :

-

The grinding force, N/mm2

- F i :

-

The grinding force per-unit area, N/mm2

- F t :

-

The tangential grinding force, N

- F n :

-

Normal grinding force, N

- N Diamond wheel speed :

-

The speed of diamond wheel, r/min

- RT :

-

The room temperature, ℃

- △ t :

-

Rotation interval time, min

- Ω s :

-

Constant speed, m/s

- V grinding wheel :

-

The workpiece volume, mm3/s or the speed ratio, μm/s

- θ :

-

Rotating angle of the grinding wheel, deg

- Ψ i :

-

The rotation angle, deg

- Ω s :

-

The constant speed, mm3/s

References

Fanara C, Shore P, Nicholls JR, Lyford N, Kelley J, Carr J, Sommer P (2006) A new Reactive Atom Plasma Technology (RAPT) for precision machining: the etching of ULE surfaces. Adv Eng Mater 8(10):933–939

Hashimoto F, Lahoti GD (2004) Optimization of set-up conditions for stability of the centerless grinding process. Ann CIRP 53(1):271–274

Mannan MA, Drew SJ, Stone BJ (2002) Torsional vibration effects in grinding. CIRP Ann 49(1):249–252

Barrenetxea D, Marquinez JI, Bediaga I, Uriarte L (2009) Continuous workpiece speed variation (CWSV): Model based practical application to avoid chatter in grinding. CIRP Ann Manuf Technol 58(1):319–322

Jiabin Xu, Liu X, Zhang Z, Wang Li, Tan R, Zhang D (2019) Controllable generation of nanofibers through a magnetic-field-assisted electrospinning design. Mater Lett 247:19–24

Chen F, Mei G, Zhao Bo, Bie W, Li G (2020) Study on the characteristics of zirconia ceramic in three-dimensional ultrasonic vibration-assisted ELID internal grinding. J Mech Sci Technol 34(1):333–344

Ahrens M, Dagen M, Denkena B, Ortmaier T (2016) An active damping method for chatter vibration in plunge grinding using electromagnetic actuators. Procedia CIRP 46:197–200

Rowe WB, Miyashita M, Koenig W (2004) Centreless grinding research and its application in advanced manufacturing technology. Ann CIRP 38(2):617–625

Klocke F, Friedrich D, Linke B, Nachmani Z (2004) Basics for in-process roundness error improvement by a functional workrest blade. Ann CIRP 53(1):275–280

Hecker RL, Ramoneda IM, Liang Steven Y (2003) Analysis of wheel topography and grit force for grinding process modeling. J Manuf Process 5(1):13–23

Kang RK, Yuan JT, Zhang YP, Ren JX (2001) Truing of diamond wheels by Laser. Key Eng Mater 202–203:137–142

Zhang H, Lieh J, Yen D, Song X, Rui X (2003) Geometry analysis and simulation in shoe centerless grinding. J Manuf Sci Eng 125:304–309

Shahriari M, Zakeri M, Razavi M, Rahimipour MR (2021) Magnesiothermic synthesis of HfB2–HfC-SiC nanocomposite by spark plasma technique. Ceram Int 47(2):2172–2179

Wu Y, Kondo T, Kato M (2005) A new centerless grinding technique using a surface grinder. J Mater Process Technol 162–163:709–717

Wu Y, Fan Y, Kato M, Wang J, Syoji K, Kuriyagawa T (2003) A new centerless grinding technique without employing a regulating wheel. Key Eng Mater 238–239:355–360

Chang HC, Junz WJJ (2008) A stochastic grinding force model considering random grit distribution. Int J Mach Tools Manuf 48(12–13):1335–1344

Li L, Jizai Fu (1980) A study of grinding force mathematical model. Ann CIRP-Manuf Technol 29(1):245–249

Guo G, Liu Z, An Q, Chen M (2011) Experimental investigation on conventional grinding of Ti-6Al-4V using SiC abrasive. Int J Adv Manuf Technol 57:135–142

Chen J, Shen J, Huang H, Xipeng Xu (2010) Grinding characteristics in high speed grinding of engineering ceramics with brazed diamond wheels. J Mater Process Technol 210(6–7):899–906

Acknowledgements

This work was funded and financially supported by the National Science and Technology Major Project of the Ministry of Science and Technology of China (Grant No. 2018ZX04015001-005), National Natural Science Foundation of China (52105467), and Startup Fund for Young Faculty at SJTU (SFYF at SJTU) (21X010500621). We wish to express gratitude for the generous support from Shanghai Jiao Tong University associate researcher Long Zhang and Tianjin University of Technology and Education (TUTE) associate Prof. Xiangyu Zhang. Also, we wish to thank Dianrong Luan for grinding process, one devote for the precision machinery offer senior expert, senior technician. The original process idea is designed by Jiabin Xu, a Ph.D. candidate under the guide from Prof. Feihu Zhang. The authors would like to thank the editors and anonymous reviewers for their objective opinions and suggestions, which greatly improved the presentation and peer-review recognition of this paper.

Funding

This work was funded and financial support by the National Science and Technology Major Project of the Ministry of Science and Technology of China (Grant No. 2018ZX04015001-005), National Natural Science Foundation of China (52105467), and Startup Fund for Young Faculty at SJTU (SFYF at SJTU) (21X010500621).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Ethical approval

The research does not involve human participants and/or animals.

Consent

Consent to submit the paper for publication has been received explicitly from all co-authors.

Conflict of interest

None. The authors have no conflicts of interest to declare that are relevant to the content of this article.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

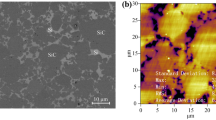

• The work shows the cold atmospheric plasma via oxygen (O2) composite methods by the active surface “free radical” is concentration higher than a single type of the precision grinding process.

• The effectiveness of surface modification be measured and evaluated by the magnitude and direction of the RB-SiC ceramic surface modification layer and removal efficiency of Si phase and SiC phase.

• In the work, we propose a new method for cold atmospheric plasma based on the precision grinding process to research on surface modification of RB-SiC ceramic hard-brittle material by precision grinding problems to test its performance. In such cases, the finish-surface quality of the RB-SiC ceramic is easy to be further improved and provide a satisfactory result at an affordable single-precision grinding process cost.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, J., Rao, X., Xu, X. et al. Investigation into the role of cold atmospheric plasma on the precision grinding of RB-SiC ceramic at room temperature. Int J Adv Manuf Technol 122, 1233–1243 (2022). https://doi.org/10.1007/s00170-022-09554-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09554-w