Abstract

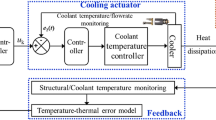

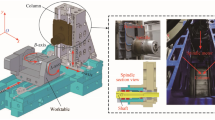

The thermal error stability (STE) of the spindle determines the machining accuracy of a precision machine tool. The “active cooling-spindle” system is regarded as a feedback control system, and the data-driven thermal error model is utilized to output feedback. In this way, the spindle thermal error can be stabilized by the homeostasis ability of the feedback control system under disturbance. Structural temperature measurements are considerably interfered by the active cooling, so the regression models trained with experimental data might output inaccurate feedback in unseen work conditions. Such inaccurate feedbacks are the primary cause for excessive fluctuations and failures of the thermal error control processes. The independence of the thermal data is analyzed, and a V-C (Vapnik–Chervonenkis) dimension–based approach is presented to estimate the generalization error bound of the regression models. Then, the model which is most likely to give acceptable performance can be selected, the reliability of the feedback can be pre-estimated, and the risk of unsatisfactory control effect will be largely reduced. Experiments under different work conditions are conducted to verify the proposed strategy. The thermal error is stabilized to be within a range smaller than 1.637 μm, and thermal equilibrium time is advanced by more than 78.3%.

Similar content being viewed by others

Availability of data and materials

All experimental data of this study are available.

Code availability

Not applicable.

References

Weng L, Gao W, Zhang D, Huang T, Chang W (2021) Analytical modelling method for thermal balancing design of machine tool structural components. Int J Mach Tools Manuf 103715

Liu K, Wu JK, Liu HB, Sun MJ, Wang YQ (2021) Reliability analysis of thermal error model based on DBN and Monte Carlo method. Mech Syst Signal Process 146:107020

Liu J, Ma C, Wang SL, Wang SB, Yang B, Shi H (2019) Thermal-structure interaction characteristics of a high-speed spindle- bearing system. Int J Mach Tools Manuf 137(1–2):42–57

Mayr J, Jedrzejewski J, Uhlmann E, Donme MA, Knapp W, Hartig F, Wendt K, Moriwaki T, Shore P, Schmitt R, Brecher C, Wu T, Wegener K (2012) Thermal issues in machine tools. CIRP Ann Manuf Technol 61(2):771–791

Cao H, Zhang XW, Chen XF (2017) The concept and progress of intelligent spindles: a review. Int J Mach Tools Manuf 112:21–52

Shi XJ, Yin B, Chen G, Zhang X, Mei XS (2021) Numerical study on two-phase flow and heat transfer characteristics of loop rotating heat pipe for cooling motorized spindle. Appl Therm Eng 192(2):116927

Li B, Cao H, Yang X, Jafar S, Zeng D (2018) Thermal energy balance control model of motorized spindle system enabling high-speed dry hobbing process. J Manuf Process 35(12):29–39

Liu T, Gao WG, Tian YL, Zhang H, Chang WF, Mao K, Zhang DW (2015) A differentiated multi-loops bath recirculation system for precision machine tools. Appl Therm Eng 76:54–63

Liu T, Gao W, Tian YL, Zhang DW, Zhang YF, Chang WF (2017) Power matching based dissipation strategy onto spindle heat generations. Appl Therm Eng 113:499–507

Grama SN, Mathur A, Badhe AN (2018) A model-based cooling strategy for motorized spindle to reduce thermal errors. Int J Mach Tools Manuf 132:3–16

Ge ZJ, Ding XH (2018) Design of thermal error control system for high-speed motorized spindle based on thermal contraction of CFRP. Int J Mach Tools Manuf 125:99–111

Lei MH, Jiang GD, Zhao L, Wang JS, Li BQ, Xia P, Yang J, Mei XS (2019) Thermal error controlling for the spindle in a precision boring machine with external cooling across coated joints. Proc Inst Mech Eng Part C J Mech Eng Sci 234(2):658–675

Liu K, Sun M, Zhu T, Wu Y, Liu Y (2016) Modeling and compensation for spindle’s radial thermal drift error on a vertical machining center. Int J Mach Tools Manuf 105:58–67

Yang J, Shi H, Feng B, Zhao L, Ma C, Mei XS (2015) Thermal error modeling and compensation for a high-speed motorized spindle. Int J Adv Manuf Technol 77(5):1005–1017

Miao E, Liu Y, Liu H, Gao Z, Li W (2015) Study on the effects of changes in temperature-sensitive points on thermal error compensation model for CNC machine tool. Int J Mach Tools Manuf 97:50–59

Mpoudeu M, Clarke B (2018) Model selection via the VC-dimension

Zhang PB, Yang ZX (2016) A novel AdaBoost framework with robust threshold and structural optimization. IEEE Trans Cybern 48(1):1–13

Ma C, Yang J, Zhao L, Mei XS, Shi H (2015) Simulation and experimental study on the thermally induced deformations of high-speed spindle system. Appl Therm Eng 86:251–268

Lei MH, Jiang GD, Yang J, Mei XS, Xia P, Shi H (2018) Improvement of the regression model for spindle thermal elongation by a boosting-based outliers detection approach. Int J Adv Manuf Technol 99(5):1389–1403

Mahdi E, Mcleod AI (2012) Improved multivariate portmanteau test. J Time Ser Anal 33(2):211–222

Hosking J (1980) The multivariate portmanteau statistic. Publ Am Stat Assoc 75(371):602–608

Lei MH, Jiang GD, Yang J, Mei XS, Xia P, Zhao L (2017) Thermal error modeling with dirty and small training sample for the motorized spindle of a precision boring machine. Int J Adv Manuf Technol 93(1–4):571–586

Miao EM, Liu Y, Liu H, Gao Z, Li W (2015) Study on the effects of changes in temperature-sensitive points on thermal error compensation model for CNC machine tool. Int J Mach Tools Manuf

Basak D, Srimanta P, Patranbis DC (2007) Support vector regression. Neural Inf Pprocess Lett Rev 11(10):203–224

Vapnik V (2013) The nature of statistical learning theory. Springer science & business media

Xu S, An X, Qiao X, Zhu LJ, Li L (2013) Multi-output least-squares support vector regression machines. Pattern Recogn Lett 34(9):1078–1084

Cherkassky V, Ma Y (2004) Practical selection of SVM parameters and noise estimation for SVM regression. Neural Netw 17(1):113–126

Sivanandam SN, Deepa SN (2008) Introduction to genetic algorithms. Springer, Berlin Heidelberg

Breiman L (2001) Random forests. Mach Learn 45(1):5–32

Zhang G, Lu Y (2012) Bias-corrected random forests in regression. J Appl Stat 39(1):151–160

Gey S, Nédélec E (2005) Model selection for CART regression trees. IEEE Trans Inf Theory 51(2):658–670

Ziarh GF, Shahid S, Ismail TB, Asaduzzaman M, Dewan A (2020) Correcting bias of satellite rainfall data using physical empirical model. Atmos Res 251:105430

Mpoudeu MT (2017) Use of Vapnik-Chervonenkis dimension in model selection

Funding

The authors disclosed receipt of the following financial support for the research, authorship, and/or publication of this article: Natural Science Basic Research Program of Shaanxi (2021JQ-475), Start-up fund of Xi’an University of Technology (451120007), the Science and Technology Major Project of Shaanxi Province (No. 2018ZDZX01-02–01), and the Shandong Tai Shan industrial leader talent project (No. 2017TSCYCX-24).

Author information

Authors and Affiliations

Contributions

Mohan Lei: Conceptualization, methodology, writing—original draft preparation. Feng Gao: Investigation, validation. Yan Li: Software. Ping Xia: Software, writing—reviewing and editing. Mengchao Wang: Validation. Jun Yang: Supervision.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lei, M., Gao, F., Li, Y. et al. Feedback control–based active cooling with pre-estimated reliability for stabilizing the thermal error of a precision mechanical spindle. Int J Adv Manuf Technol 121, 2023–2040 (2022). https://doi.org/10.1007/s00170-022-09471-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09471-y