Abstract

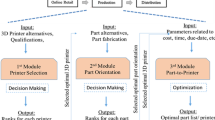

Additive manufacturing (AM) is a promising manufacturing technology; it has great manufacturing capabilities and large material diversity, making it applicable for many applications. However, the limited information related to AM processes, materials, and rules restricts its potential popularity over traditional manufacturing methods. For a particular application, the choice of available AM process/machine and material is critical to the application’s quality, mechanical properties, and other important factors. Moreover, the large number of AM processes/machines and materials and the overlap among them in terms of capability and functionality further complicate the selection task. AM service selection as a problem has three essential aspects, and all support systems that are built to help users select the optimal AM service must consider these aspects during the system development stage. These aspects are the AM resource capability information source, user intervention, and the methodology suggesting the best AM resources that meet user requirements. These aspects actually represent AM resource definition accuracy and availability, selection system usability, and reliability. This study analyses the essence of these three aspects, reviews the literature, and develops a new AM selection system framework that enhances system functionality regarding these aspects. First, 3D printing service providers in the proposed system are considered the source of AM resource capability information to expand AM service options to users, provide accurate resource definitions, and ensure their availability. Second, the proposed system applied the posteriori-based multicriteria decision-making approach through the integration of decision making trial and evaluation laboratory (DEMATEL), analytic hierarchy process (AHP), and modified Technique for Order Preference by Similarities to Ideal Solution (TOPSIS) techniques. This greatly minimizes user inputs during AM service selection process, fully supports the DFAM (Design for additive manufacturing) concept, and maintains the accuracy of final selection decisions.

Similar content being viewed by others

Abbreviations

- AM:

-

Additive manufacturing

- DEMATEL:

-

Decision making trial and evaluation laboratory

- TOPSIS:

-

Technique for Order Preference by Similarities to Ideal Solution

- AHP:

-

Analytic hierarchy process

- DFAM:

-

Design for additive manufacturing

- AM resources:

-

AM machines and materials

- AM service:

-

AM process/machine and material at a material level

- MDDV tool:

-

Multidimensional data visualization tool

- ME:

-

AM material extrusion process

- ABS:

-

Acrylonitrile butadiene styrene

- PLA:

-

Polylactic acid

- PBF:

-

AM Powder bed fusion process

- PA :

-

Polyamide

- User preference:

-

Criteria relative importance weights assigned by user

References

Baumers M, Beltrametti L, Gasparre A, Hague R (2017) Informing additive manufacturing technology adoption: total cost and the impact of capacity utilization. Int J Prod Res 55:6957–6970

Gibson I (2015) Additive Manufacturing Technologies 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing. Springer

ISO/ASTM 52900 (2015) Additive manufacturing—general principles—terminology. International Organization for Standardization. Geneva, Switzerland

Mueller B (2012) Additive manufacturing technologies – rapid prototyping to direct digital manufacturing. Assem Autom 32(2). ISSN 0144-5154

Srivastava S, Garg RK, Sharma VS et al (2020) Multi-physics continuum modelling approaches for metal powder additive manufacturing: a review. Rapid Prototyp J 26(4):737–764

Gao W, Zhang Y, Ramanujan D, Ramani K et al (2015) The status, challenges, and future of additive manufacturing in engineering. Comput Aided Des 69:65–89

Raigar J, Sharma VS, Srivastava S et al (2020) A decision support system for the selection of an additive manufacturing process using a new hybrid MCDM technique. Sādhanā 45:1–14

Qin Y, Qi Q, Scott PJ, Jiang X (2020) An additive manufacturing process selection approach based on fuzzy Archimedean weighted power Bonferroni aggregation operators. Robotics and Computer-Integrated Manufacturing 64:101926

Wang Y, Blache R, Xu X (2017) Selection of additive manufacturing processes. Rapid Prototyp J 23(2):434–447

Pham DT, Gault RS (1998) A comparison of rapid prototyping technologies. Int J Mach Tools Manuf 38(10–11):1257–1287

Moylan S, Slotwinski J, Cooke A, Jurrens K, Donmez MA (2012) Proposal for a standardized test artifact for additive manufacturing machines and processes. In: Proceedings of the 23rd Annual International Solid Freeform Fabrication Symposium. University of Texas at Austin, pp 902

Roberson DA, Espalin D, Wicker RB (2013) 3D printer selection: a decision-making evaluation and ranking model. Virtual and Physical Prototyping 8(3):201–212

Kadkhoda-Ahmadi S, Hassan A, Asadollahi-Yazdi E (2019) Process and resource selection methodology in design for additive manufacturing. Int J Adv Manuf Technol 104(5):2013–2029

Borille A, Gomes J, Meyer R, Grote K (2010) Applying decision methods to select rapid prototyping technologies. Rapid Prototyp J 16(1):50–62

Kim GD, Oh YT (2008) A benchmark study on rapid prototyping processes and machines: quantitative comparisons of mechanical properties, accuracy, roughness, speed, and material cost. Proc Inst Mech Eng B J Eng Manuf 222(2):201–215

Zhang Y, Xu Y, Bernard A (2014) A new decision support method for the selection of RP process: knowledge value measuring. Int J Comput Integr Manuf 27(8):747–758

Mançanares CG, Zancul EDS, da Silva JC, Miguel PAC (2015) Additive manufacturing process selection based on parts’ selection criteria. J Adv Manuf Technol 80(5):1007–1014

Thompson MK, Moroni G, Vaneker T, Fadel G et al (2016) Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann 65(2):737–760

Wang Y, Zhong RY, Xu X (2018) A decision support system for additive manufacturing process selection using a hybrid multiple criteria decision-making method. Rapid Prototyp J 24(9):1544–1553

Liu W, Zhu Z, Ye S (2020) A decision-making methodology integrated in product design for additive manufacturing process selection. Rapid Prototyp J 26(5):895–909

Lan H, Ding Y, Hong J (2005) Decision support system for rapid prototyping process selection through integration of fuzzy synthetic evaluation and an expert system. Int J Prod Res 43(1):169–194

Munguía J, Lloveras J, Llorens S, Laoui T (2010) Development of an AI-based rapid manufacturing advice system. Int J Prod Res 48(8):2261–2278

Papakostas N, Newell A, George A (2020) An agent-based decision support platform for additive manufacturing applications. Appl Sci 10(14):4953

Rao RV, Padmanabhan KK (2007) Rapid prototyping process selection using graph theory and matrix approach. J Mater Process Technol 194(1–3):81–88

Liao S, Wu MJ, Huang CY, Kao YS, Lee TH (2014) Evaluating and enhancing three-dimensional printing service providers for rapid prototyping using the DEMATEL based network process and VIKOR. Math Probl Eng

Yurdakul M, Ic YT (2009) Application of correlation test to criteria selection for multi criteria decision making (MCDM) models. Int J Adv Manuf Technol 40(3):403–412

Velasquez M, Hester PT (2013) An analysis of multi-criteria decision making methods. Int J Oper Res 10(2):56–66

Marler RT, Arora JS (2004) Survey of multi-objective optimization methods for engineering. Struct Multidiscip Optim 26(6):369–395

Ishizaka A, Nemery P (2013) Multi-criteria decision analysis: methods and software. John Wiley & Sons

Miller SW, Simpson TW, Yukish MA et al (2013) Preference construction, sequential decision making, and trade space exploration. In International Design Engineering Technical Conferences and Computers and Information in Engineering Conference 55881:V03AT03A014. Am Soc Mech Eng

Uz Zaman UK, Rivette M, Siadat A, Mousavi SM (2018) Integrated product-process design: Material and manufacturing process selection for additive manufacturing using multi-criteria decision making. Robot Comput Integr Manuf 51:169–180

Netto JJ, Ragoni IG, Santos LF, Silveira ZC (2019) Selecting low-cost 3D printers using the AHP method: a case study. SN Applied Sciences 1(4):1–12

Si S L, You X Y, Liu H C, Zhang P (2018) DEMATEL technique: a systematic review of the state-of-the-art literature on methodologies and applications. Math Probl Eng

ISO 17296–3 (2014) Additive manufacturing—general principles—Part 3: Main characteristics and corresponding test methods. International Organisation for Standardisation. Geneva, Switzerland

ISO 17296–2 (2015) Additive manufacturing—general principles—Part 2: Overview of process categories and feedstock. International Organisation for Standardisation. Geneva, Switzerland

Tofail SA, Koumoulos EP, Bandyopadhyay A et al (2018) Additive manufacturing: scientific and technological challenges, market uptake and opportunities. Mater Today 21(1):22–37

Yim S, Rosen D (2012) Build time and cost models for additive manufacturing process selection. In International Design Engineering Technical Conferences and Computers and Information in Engineering Conference 45011: 375–382. Am Soc Mech Eng

Thomas DS, Gilbert SW (2014) Costs and cost effectiveness of additive manufacturing. NIST Spec Publ 1176:12

Liu HC, You JX, Ding XF, Su Q (2015) Improving risk evaluation in FMEA with a hybrid multiple criteria decision making method. Int J Qual Reliab

Wang Y, Blache R, Zheng P, Xu X (2018) A knowledge management system to support design for additive manufacturing using Bayesian networks. J Mech Des 140(5):051701

Rosen DW, Gibson I (2002) Decision support and system selection for RP. In: Gibson I (ed) Software solutions for rapid prototyping, professional engineering publishing limited. Suffolk, UK, pp 95–127

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Algunaid, K.M.A., Liu, J. Decision support system to select a 3D printing process/machine and material from a large-scale options pool. Int J Adv Manuf Technol 121, 7643–7659 (2022). https://doi.org/10.1007/s00170-022-09362-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09362-2