Abstract

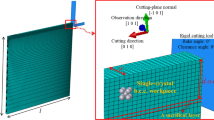

In this work, an analytical oblique cutting model has been proposed. This model is building on a one-dimensional approach for which the chip is formed by shearing within the primary shear zone. The impact of the material anisotropy is considered through a crystal plasticity-based constitutive model. The cutting forces and the corresponding specific energies are estimated using the physical-based normal shear angles procedure and Merchant’s normal shear angle procedure. The model is validated using the experimental data obtained from the literature. According to the results, the numerical and experimental findings are in good agreement. The model is then used to evaluate the impact of the crystallographic orientations and the machining parameters during oblique turning. The results show that the impact of the machining parameters on the cutting forces is correctly depicted. It is also demonstrated that whatever the crystal orientations are, the signature of cutting forces during oblique turning shows a fourfold symmetry. In addition, the variation of the cutting forces according to the rotation angle follows the evolution of the associated cumulative shear strain required to accommodate the plastic deformation. Finally, the simulations demonstrate that the chip flow angle, which has a significant effect on chip control, is greatly affected by the orientation of the single crystal.

Similar content being viewed by others

Availability of data and material

Not applicable.

Code availability

Not applicable.

References

Wang J (2001) Development of a chip flow model for turning operations. Int J Mach Tools Manuf 41(9):1265–1274. https://doi.org/10.1016/S0890-6955(01)00022-0. http://www.sciencedirect.com/science/article/pii/S0890695501000220

Arsecularatne J, Mathew P, Oxley P (1995) Prediction of chip flow direction and cutting forces in oblique machining with nose radius tools. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture 209(4):305–315

Parakkal G, Zhu R, Kapoor SG, DeVor RE (2002) Modeling of turning process cutting forces for grooved tools. Int J Mach Tools Manuf 42(2):179–191. https://doi.org/10.1016/S0890-6955(01)00121-3. http://www.sciencedirect.com/science/article/pii/S0890695501001213

Moufki A, Devillez A, Dudzinski D, Molinari A (2004) Thermomechanical modelling of oblique cutting and experimental validation. Int J Mach Tools Manuf 44(9):971–989. https://doi.org/10.1016/j.ijmachtools.2004.01.018. http://www.sciencedirect.com/science/article/pii/S0890695504000215

Moriwaki T (1989) Machinability of copper in ultra-precision micro diamond cutting. CIRP Annals 38(1):115–118. https://doi.org/10.1016/S0007-8506(07)62664-X. http://www.sciencedirect.com/science/article/pii/S000785060762664X

Sato M, Kato Y, Tsutiya K (1979) Effects of crystal orientation on the flow mechanism in cutting aluminum single crystal. Trans Jpn Inst Metals 20(8):414–422. https://doi.org/10.2320/matertrans1960.20.414

Rusnaldy, Ko TJ, Kim HS (2007) Micro-end-milling of single-crystal silicon. Int J Mach Tools Manuf 47(14):2111–2119. https://doi.org/10.1016/j.ijmachtools.2007.05.003. http://www.sciencedirect.com/science/article/pii/S0890695507001058

Min S, Dornfeld D, Inasaki I, Ohmori H, Lee D, Deichmueller M, Yasuda T, Niwa K (2006) Variation in machinability of single crystal materials in micromachining. CIRP Annals 55(1):103–106. https://doi.org/10.1016/S0007-8506(07)60376-X

Sato MYT, Shimizu Y, Takabayashi T (1991) A study on the microcutting of aluminum single crystals. JSME international Journal Ser 3, Vibration, Control Engineering, Engineering for Industry 34(4):540–545. https://doi.org/10.1299/jsmec1988.34.540

Ueda K, Iwata K, Nakayama K (1980) Chip formation mechanism in single crystal cutting of \(\beta\)-brass. CIRP Annals 29(1):41–46. https://doi.org/10.1016/S0007-8506(07)61292-X. http://www.sciencedirect.com/science/article/pii/S000785060761292X

Cohen PH (1982) The orthogonal in-situ machining of single and polycrystalline aluminum and copper. PhD thesis, The Ohio State University

Choong ZJ, Huo D, Degenaar P, O’Neill A (2019) Micro-machinability and edge chipping mechanism studies on diamond micro-milling of monocrystalline silicon. J Manuf Process 38:93–103. https://doi.org/10.1016/j.jmapro.2019.01.004. http://www.sciencedirect.com/science/article/pii/S1526612519300040

Konig W, Spenrath N (1991) The influence of the crystallographic structure of the substrate material on surface quality and cutting forces in micromachining. In: Seyfried P, Kunzmann H, McKeown P, Weck M (eds) Progress in Precision Engineering. Springer, Berlin Heidelberg, Berlin, Heidelberg, pp 141–152

Moronuki N, Liang Y, Furukawa Y (1994) Experiments on the effect of material properties on microcutting processes. Precis Eng 16(2):124–131. https://doi.org/10.1016/0141-6359(94)90197-X. http://www.sciencedirect.com/science/article/pii/014163599490197X

Zhou M, Ngoi BKA (2001) Effect of tool and workpiece anisotropy on microcutting processes. Proc Inst Mech Eng B J Eng Manuf 215(1):13–19. https://doi.org/10.1243/0954405011515091

Moriwaki T, Okuda K, Shen GJ (1993) Study of ultraprecision orthogonal microdiamond cutting of single-crystal copper. JSME International Journal Ser C, Dynamics, Control, Robotics, Design and Manufacturing 36(3):400–406

Yuan Z, Lee W, Yao Y, Zhou M (1994) Effect of crystallographic orientation on cutting forces and surface quality in diamond cutting of single crystal. CIRP Annals 43(1):39–42. https://doi.org/10.1016/S0007-8506(07)62159-3. http://www.sciencedirect.com/science/article/pii/S0007850607621593

Merchant ME (1945) Mechanics of the metal cutting process. I. orthogonal cutting and a type 2 chip. J Appl Phys 16(5):267–275

Sato M, Kato Y, Aoki S, Ikoma A (1983) Effects of crystal orientation on the cutting mechanism of the aluminum single crystal: 2nd report: on the (111) plane and the (112) end cutting. Bulletin of JSME 26(215):890–896. https://doi.org/10.1299/jsme1958.26.890

Lee W, To S, Sze Y, Cheung C (2003) Effect of material anisotropy on shear angle prediction in metal cutting-a mesoplasticity approach. Int J Mech Sci 45(10):1739–1749. https://doi.org/10.1016/j.ijmecsci.2003.09.024. https://www.sciencedirect.com/science/article/pii/S0020740303002297. 6th Asia-Pacific Symposium on Advances in Engineering Plasticity and its Applications

Kota N, Rollett AD, Ozdoganlar OB (2011a) A rate-sensitive plasticity-based model for machining of face-centered cubic single-crystals—Part I: model development. J Manuf Sci Eng 133(3):031017. https://doi.org/10.1115/1.4004134

Kota N, Rollett AD, Ozdoganlar OB (2011b) A rate-sensitive plasticity-based model for machining of FCC single-crystals—Part II: Model calibration and validation. J Manuf Sci Eng 133(3):031018. https://doi.org/10.1115/1.4004135

Demir E (2008) Taylor-based model for micro-machining of single crystal FCC materials including frictional effects-application to micro-milling process. Int J Mach Tools Manuf 48(14):1592–1598. https://doi.org/10.1016/j.ijmachtools.2008.07.002

Demir E (2009) A method to include plastic anisotropy to orthogonal micromachining of FCC single crystals. Int J Adv Manuf Technol 36:474–481. https://doi.org/10.1080/14786445108561065

Reid CN (2016) Deformation geometry for materials scientists: international series on materials science and technology, vol 11. Elsevier

Lee W, Zhou M (1993) A theoretical analysis of the effect of crystallographic orientation on chip formation in micromachining. Int J Mach Tools Manuf 33(3):439–447. https://doi.org/10.1016/0890-6955(93)90050-5. https://www.sciencedirect.com/science/article/pii/0890695593900505

Lee WB, Cheung CF, To S (2002) A microplasticity analysis of micro-cutting force variation in ultra-precision diamond turning. J Manuf Sci Eng 124(2):170–177

Wang S, An C, Zhang F, Wang J, Lei X, Zhang J (2016) An experimental and theoretical investigation on the brittle ductile transition and cutting force anisotropy in cutting KDP crystal. Int J Mach Tools Manuf 106:98–108. https://doi.org/10.1016/j.ijmachtools.2016.04.009. https://www.sciencedirect.com/science/article/pii/S0890695516300347

Lee YJ, Kumar AS, Wang H (2021) Beneficial stress of a coating on ductile-mode cutting of single-crystal brittle material. Int J Mach Tools Manuf 168:103787. https://doi.org/10.1016/j.ijmachtools.2021.103787. https://www.sciencedirect.com/science/article/pii/S0890695521000961

Moufki A, Dudzinski D, Molinari A, Rausch M (2000) Thermoviscoplastic modelling of oblique cutting: forces and chip flow predictions. Int J Mech Sci 42(6):1205–1232. https://doi.org/10.1016/S0020-7403(99)00036-3. http://www.sciencedirect.com/science/article/pii/S0020740399000363

Kota N, Ozdoganlar O (2008) A simplified model for orthogonal micromachining of FCC single-crystal materials. Trans NAMRI SME 36:193–200

Dunne F, Petrinic N (2005) Introduction to computational plasticity. Oxford University Press on Demand

Follansbee PS, Kocks UF (1988) A constitutive description of the deformation of copper based on the use of the mechanical threshold stress as an internal state variable. Acta Metall 36(1):81–93. https://doi.org/10.1016/0001-6160(88)90030-2. http://www.sciencedirect.com/science/article/pii/0001616088900302

Goto DM, Garrett RK, Bingert JF, Chen SR, Gray GT (2000b) The mechanical threshold stress constitutive-strength model description of HY-100 steel. Metall Mater Trans A 31(8):1985–1996

Goto DM, Bingert JF, Reed WR, Jr RKG (2000a) Anisotropy-corrected MTS constitutive strength modeling in HY-100 steel. Scr Mater 12(42):1125–1131

Kocks UF (2001) Realistic constitutive relations for metal plasticity. Mater Sci Eng A 317(1):181–187. https://doi.org/10.1016/S0921-5093(01)01174-1. http://www.sciencedirect.com/science/article/pii/S0921509301011741

Kok S, Beaudoin AJ, Tortorelli DA (2002) A polycrystal plasticity model based on the mechanical threshold. Int J Plast 18(5):715–741. https://doi.org/10.1016/S0749-6419(01)00051-1. http://www.sciencedirect.com/science/article/pii/S0749641901000511

Gourdin W, Lassila D (1991) Flow stress of OFE copper at strain rates from \(10^{-3}\) to \(10^{4}\) s\(^{-1}\): Grain-size effects and comparison to the mechanical threshold stress model. Acta Metall Mater 39(10):2337–2348. https://doi.org/10.1016/0956-7151(91)90015-S. http://www.sciencedirect.com/science/article/pii/095671519190015S

Oxley PLB, Young HT (1990) The mechanics of machining: an analytical approach to assessing machinability. Ellis Horwood Publisher, Chichester, England

Stabler GV (1951) The fundamental geometry of cutting tools. Proc Inst Mech Eng 165(1):14–26. https://doi.org/10.1243/PIME_PROC_1951_165_008_02

Brown R, Armarego E (1964) Oblique machining with a single cutting edge. International Journal of Machine Tool Design and Research 4(1):9–25. https://doi.org/10.1016/0020-7357(64)90006-X

WKLUK (1972) The direction of chip flow in oblique cutting. Int J Prod Res 10(1):67–76. https://doi.org/10.1080/00207547208929906

Stabler G (1964) The chip flow law and its consequences. Advances in Machine Tool Design and Research 5:243–251

Funding

This work is supported by the French State (ANR) through the program “Investment for the future” referenced by ANR-11-LABX-0008-01 (LabEx DAMAS). Authors would like to acknowledge the LabEx DAMAS for the financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflicts of interest

The authors declare no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

1.1 Implementation of the analytical oblique cutting model

Rights and permissions

About this article

Cite this article

Ben Boubaker, H., Moufki, A., Nouari, M. et al. A crystal plasticity-based model for oblique cutting of face-centered cubic single crystals. Int J Adv Manuf Technol 121, 429–448 (2022). https://doi.org/10.1007/s00170-022-09238-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09238-5