Abstract

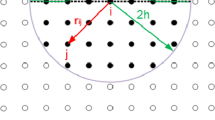

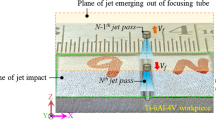

The erosion footprint profiles of abrasive waterjet (AWJ) mainly depend on the jet-plume’s capabilities, erosion angles, and the machined workpiece’s physical properties. Therefore, the result profiles obtained by successfully simulating AWJ processing are attributed to the accurate erosion field characteristics. In this article, an attempt has been made to develop a fluid–structure interface (FSI) coupling model to simulate the AWJ micro-hole erosion profiles on the workpiece over a range of water pressure, stand-off-distance, abrasive flow rate, and different impingement angles. A quarter of the 3-dimensional erosion model was proposed, which could efficiently and qualitatively simulate AWJ drilling footprint profiles without consuming much storage space and computation time. Firstly, the formation process of erosion field was described, the stagnation zone under different erosion field conditions was discussed, and the differential characteristics of the AWJ erosion field were obtained. Then, the FSI results were verified by comparing the simulated profiles with the corresponding experimental data. Ti6Al4V was adopted as the simulation workpiece material, which has remarkable comprehensive mechanical properties such as high-specific strength, light density, low thermal conductivity, and was widely used in aerospace fields. It turned out that the FSI model intuitively reflects the characteristics of the erosion field on the workpiece and the influence of different parameters on the erosion footprint profiles. The simulated footprints profiles obtained were shown in good agreement with experimental data, and the maximum error was below 14%. The simulation result of this research was of great significance for future in-depth exploration of erosion field characteristics and practical guidance.

Similar content being viewed by others

Data availability

The data sets supporting the results of this article are included within the article.

References

Axinte DA, Karpuschewski B, Kong MC, Beaucamp AT, Anwar S, Miller D, Petzel M (2014) High energy fluid jet machining (HEFJet-Mach): from scientific and technological advances to niche industrial applications. CIRP Ann 63(2):751–771

Manu R, Babu NR (2009) An erosion-based model for abrasive waterjet turning of ductile materials. Wear 266(11–12):1091–1097

ElTobgy MS, Ng E, Elbestawi MA (2005) Finite element modeling of erosive wear. Int J Mach Tools Manuf 45(11):1337–1346

Schwartzentruber J, Spelt JK, Papini M (2018) Modelling of delamination due to hydraulic shock when piercing anisotropic carbon-fiber laminates using an abrasive waterjet. Int J Mach Tools Manuf 132:81–95

Anwar S, Axinte DA, Becker AA (2013) Finite element modelling of overlapping abrasive waterjet milled footprints. Wear 303(1–2):426–436

Torrubia PL, Axinte DA, Billingham J (2015) Stochastic modelling of abrasive waterjet footprints using finite element analysis. Int J Mach Tools Manuf 95:39–51

Thongkaew K, Wang J, Yeoh GH (2019) Impact characteristics and stagnation formation on a solid surface by a supersonic abrasive waterjet. Int J Extreme Manuf 1(4):045004

Lv Z, Hou RG, Tian YB, Huang CZ, Zhu HT (2018) Investigation on flow field of ultrasonic-assisted abrasive waterjet using CFD with discrete phase model. Int J Adv Manuf Technol 96(5–8):1–10

Ahmed DH, Naser J, Deam RT (2016) Particles impact characteristics on cutting surface during the abrasive water jet machining: Numerical study. J Mater Process Technol 232:116–130

Wang RH, Wang MB (2010) A two-fluid model of abrasive waterjet. J Mater Process Technol 210(1):190–196

Jiang HX, Liu ZH, Gao KD (2017) Numerical simulation on rock fragmentation by discontinuous waterjet using coupled SPH/FEA method. Powder Technol 312:248–259

Yu F, Wang JM, Liu FH (2011) Numerical simulation of single particle acceleration process by SPH coupled FEM for abrasive waterjet cutting. Int J Adv Manuf Technol 59(1–4):193–200

Ma L, Bao RH, Guo YM (2008) Waterjet penetration simulation by hybrid code of SPH and FEA. Int J Impact Eng 35(9):1035–1042

Gong WJ, Wang JM, Gao N (2010) Numerical simulation for abrasive water jet machining based on ALE algorithm. Int J Adv Manuf Technol 53(1–4):247–253

Rao A (2003) Fluid—solid interaction analysis using ANSYS/multiphysics. Comput Fluid Solid Mech 1492–1496

Narayanan C, Balz R, Weiss DA, Heiniger KC (2013) Modelling of abrasive particle energy in water jet machining. J Mater Process Technol 213(12):2201–2210

Zhu HT, Huang CZ, Wang J, Li QL, Che CL (2009) Experimental study on abrasive waterjet polishing for hard–brittle materials. Int J Mach Tools Manuf 49(7–8):569–578

Haider A, Levenspiel O (1989) Drag coefficient and terminal velocity of spherical and nonspherical particles. Powder Technol 58(1):63–70

Morsi SA, Alexander AJ (1972) An investigation of particle trajectories in two-phase flow systems. J Fluid Mech 55(2):193–208

Huang W, Wei LQ, Debela TF, Chen HY, Zhou LB, Yuan JL, Ma Y (2022) Crystallographic orientation effect on the polishing behavior of LiTaO3 single crystal and its correlation with strain rate sensitivity. Ceram Int 48(6):7766–7777

Johnson GR, Cook WH (1985) Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng Fracture Mech 21(1):31–48

Liu H. (2004) A study of the cutting performance in abrasive waterjet contouring of alumina ceramics and associated jet dynamic characteristics [D]; Queensland University of Technology

Ahmad JY (2009) Machining of polymer composites. Springer, New York

Matsumura T, Muramatsu T, Fueki S (2011) Abrasive water jet machining of glass with stagnation effect. CIRP Ann Manuf Technol 60(1):355–358

Funding

This work is supported by the National Key Research and Development Project (2018YFB2001603), Joint Fund of MOE and GAD (6141A02022133), NSFC-Liaoning Joint Fund (U1708256, U1908232), and Fundamental Research Funds for the Central Universities (DUT18GF104).

Author information

Authors and Affiliations

Contributions

Yemin Yuan conceived of the study, designed the method and wrote the manuscript. All authors were involved in collecting and analyzing the data, also revisions.

Corresponding author

Ethics declarations

Consent for publication

All authors agree to transfer the copyright of this article to the publisher.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yuan, Y., Chen, J. & Gao, H. Erosion field characteristics of depth-control micro-hole profiles machined by abrasive waterjet based on FSI coupling. Int J Adv Manuf Technol 120, 7575–7593 (2022). https://doi.org/10.1007/s00170-022-09172-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09172-6