Abstract

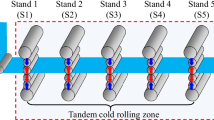

The thickness error of the thin strip determines the product quality of thin strip. As a typical dynamic continuous non-Gaussian process, the thin strip has complex irregular noise, and the general prediction method will produce significant errors. According to the rolling characteristics of thin strip, a radial basis function neural network based on variational Bayesian Gaussian mixture clustering algorithm (VBGM-RBF) is proposed to predict the thickness of cold-rolled thin strip. The production data of 160000 sets of cold-rolled strips are obtained by removing outliers according to the data characteristics by the combination of manual selection, isolated forest algorithm, and Bessel formula. Considering the mean square error (MSE) and correlation coefficient (R\(^{2}\)), the parameter settings of RBF neural network and optimization algorithm are studied to obtain the optimal model. This paper compares the prediction performance of RBF neural network optimized by different clustering algorithms, tests the prediction error of adding noise samples in the neural network, and analyzes the influencing factors of strip thickness. The results show that VBGM-RBF has the highest prediction accuracy compared with some traditional RBF neural networks. The MSE of the VBGM-RBF model is \(0.5053\) \(\mu\)m\(^{2}\), the maximum error percentage (MPE) is 1.842\(\%\), and the absolute error of 99.40\(\%\) of the predicted data is less than 2\(\mu\)m. In the analysis of the factors affecting the thickness, the model is consistent with the physical law of thin strip rolling. VBGM-RBF model has strong learning ability and generalization performance and can be well-applied to the production of thin strip steel.

Similar content being viewed by others

Availability of data and material

The datasets used or analyzed during the current study are available from the corresponding author on reasonable request.

Code availability

The code used in the current study is available from the corresponding author on reasonable request.

References

Wang DC, Liu HM, Liu J (2017) Research and development trend of shape control for cold rolling strip. Chinese Journal of Mechanical Engineering 30(5):1248–1261

Deng JF, Sun J, Peng W, Hu YH, Zhang DH (2019) Application of neural networks for predicting hot-rolled strip crown. Appl Soft Comput 78:119–131

Stone M (1953) Rolling of thin strip. Iron and Steel Engineer 2:115–128

Stone M (1956) Rolling of thin strip. Iron and Steel Engineer 33:55–76

Fleck N, Johnson K, Mear M, Zhang LC (1992) Cold rolling of foil. Proc Inst Mech Eng B J Eng Manuf 206(2):119–131

Fleck N, Johnson K (1987) Towards a new theory of cold rolling thin foil. Int J Mech Sci 29(7):507–524

Sutcliffe M, Rayner P (1998) Experimental measurements of load and strip profile in thin strip rolling. Int J Mech Sci 40(9):887–899

Stockert S, Wehr M, Lohmar J, Hirt G, Abel D (2018) Improving the thickness accuracy of cold rolled narrow strip by piezoelectric roll gap control at high rolling speed. CIRP Ann 67(1):313–316

Prinz K, Steinboeck A, Kugi A (2018) Optimization-based feedforward control of the strip thickness profile in hot strip rolling. J Process Control 64:100–111

Hu YJ, Sun J, Peng W, Zhang DH (2021) Nash equilibrium-based distributed predictive control strategy for thickness and tension control on tandem cold rolling system. J Process Control 97:92–102

Müller M, Prinz K, Steinboeck A, Schausberger F, Kugi A (2020) Adaptive feedforward thickness control in hot strip rolling with oil lubrication. Control Eng Pract 103:104584

Ren ZK, Xiao H, Liu X, Wang GF (2018) Experimental and theoretical analysis of roll flattening in the deformation zone for ultra-thin strip rolling. Ironmaking & Steelmaking 45(9):805–812

Jiang ZY, Wei DB, Tieu AK (2009) Analysis of cold rolling of ultra thin strip. J Mater Process Technol 209(9):4584–4589

Wang QL, Sun J, Liu YM, Wang PF, Zhang DH (2017) Analysis of symmetrical flatness actuator efficiencies for UCM cold rolling mill by 3D elastic-plastic fem. Int J Adv Manuf Technol 92(1–4):1371–1389

Liu X, Xiao H (2020) Theoretical and experimental study on the producible rolling thickness in ultra-thin strip rolling. J Mater Process Technol 278:116537

Portmann NF, Lindhoff D, Sorgel G, Gramckow O (1995) Application of neural networks in rolling mill automation. Iron Steel Eng 72(2):33–36

Alaei H, Salimi M, Nourani A (2016) Online prediction of work roll thermal expansion in a hot rolling process by a neural network. Int J Adv Manuf Technol 85(5):1769–1777

Xie Q, Suvarna M, Li J, Zhu X, Cai J, Wang X (2021) Online prediction of mechanical properties of hot rolled steel plate using machine learning. Materials & Design 197:109201

Wang Y, Li C, Peng L, An R, Jin X (2021) Application of convolutional neural networks for prediction of strip flatness in tandem cold rolling process. J Manuf Process 68:512–522

Zhang L, Liu M, Sun L, Li X (2014) A strip thickness prediction algorithm using extreme learning machine with improved PSO. Int J Inf Comput Sci 11(18):6763–6773

Hu Y, Sun J, Peng W, Zhang DH (2020) A novel forecast model based on CF-PSO-SVM approach for predicting the roll gap in acceleration and deceleration process. Eng Comput

Mao K, Yang YL, Huang Z, Yang D (2020) Coating thickness modeling and prediction for hot-dip galvanized steel strip based on GA-BP neural network. In: 2020 Chinese Control And Decision Conference (CCDC). IEEE, pp. 3484–3489

Wu Q, Tang QH, Li WG, Zhang LP (2018) Strip thickness prediction based on GA-BP neural network and sensitivity analysis. Journal of Wuhan University of Science and Technology 41(01):32–36

Cassidy MJ, Penny WD (2002) Bayesian nonstationary autoregressive models for biomedical signal analysis. IEEE Trans Biomed Eng 49(10):1142–1152

Ksantini R, Boufama B, Ziou D, Colin B (2010) A novel Bayesian logistic discriminant model: an application to face recognition. Pattern Recogn 43(4):1421–1430

Watanabe S, Minami Y, Nakamura A, Ueda N (2004) Variational bayesian estimation and clustering for speech recognition. IEEE Transactions on Speech and Audio Processing 12(4):365–381

Orguner U (2012) A variational measurement update for extended target tracking with random matrices. IEEE Trans Signal Process 60(7):3827–3834

Zhang SH, Xin JL, Che LZ (2021) Modeling of rolling force for thick plate of multicomponent alloys and its application on thickness prediction. Frontiers in Materials 398

Moody J, Darken CJ (1989) Fast learning in networks of locally-tuned processing units. Neural Comput 1(2):281–294

Xiang Z, Xiao Z, Wang D, Li X (2016) A gaussian mixture framework for incremental nonparametric regression with topology learning neural networks. Neurocomputing 194:34–44

Attias H (1999) A variational Baysian framework for graphical models. Adv Neural Inf Proces Syst 12

Nasios N, Bors AG (2006) Variational learning for Gaussian mixture models. IEEE Trans Syst Man Cybern B Cybern 36(4):849–862

Roberts SJ, Penny WD (2002) Variational Bayes for generalized autoregressive models. IEEE Trans Signal Process 50(9):2245–2257

Bishop CM, Nasrabadi NM (2006) Pattern recognition and machine learning. vol 4

Ishikawa Y, Takeuchi I, Nakano R (2010) Multi-directional search from the primitive initial point for Gaussian mixture estimation using variational Bayes method. Neural Netw 23(3):356–364

Funding

Partial financial support was received from the National Science Foundation of China (Nos.:51775038).

Author information

Authors and Affiliations

Contributions

X. Zhou contributed to the conception of the study; Y. Huang performed the experiment and the data analyses and wrote the manuscript; Z. Gao helped perform the analysis with constructive discussions.

Corresponding author

Ethics declarations

Ethics approval

The manuscript is approved by all authors for publication. I would like to declare on behalf of my co-authors that the work described was original research that has not been published previously, and is not under consideration for publication elsewhere, in whole or in part.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflicts of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Huang, Y., Zhou, X. & Gao, Z. Thickness prediction of thin strip cold rolling based on VBGM-RBF. Int J Adv Manuf Technol 120, 5865–5884 (2022). https://doi.org/10.1007/s00170-022-09122-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09122-2