Abstract

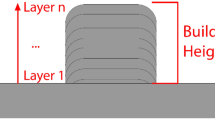

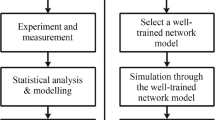

Optoelectronic components are becoming more complex and functional, but they must be miniaturized to achieve portability. The roll-to-roll UV embossing process is used to produce a light guide film to replace the light guide plate in a backlight module. To improve replicability, this study uses a deep learning-based optimization (DLBO) system. Deep learning requires a large amount of experimental data, but it is impractical for manufacturing. The DLBO system comprises a data generator, a model generator, and an optimal factor generator. The data generator generates massive labeled data by using a limited number of Taguchi experiments to predict the quality characteristic for each combination. The model generator produces an optimal neural network model that conforms to the input data. The optimal factor generator uses the model that is produced by the model generator as the objective function to determine the optimal factors. Verification experiments show that a DLBO system can successfully predict the height of a microstructure. This system also determines the optimal process conditions. The measured height of the microstructure is 1.27 μm higher than the result with Taguchi optimization, and the replicability is 90%. For the optimal conditions using the DLBO system, the roll-to-roll UV embossed film has the best light guiding properties. The results show that the optimal conditions that are determined using the DLBO system produce light guide films with better optical qualities than the Taguchi method.

Similar content being viewed by others

References

Yao D, Kim B (2002) Simulation of the filling process in micro channels for polymeric materials. J. Micromech Microeng. 12(5):604–610. stacks.iop.org/JMM/12/604

Heckele M (1998) Hot embossing – the molding technique for microstructures. Microsyst Technol 4(3):122–124. https://doi.org/10.1007/s005420050112

Tan H, Gilbertson A, Chou SY (1998) Roller nanoimprint lithography. J Vac Sci Technol, B 16(6):3926–3928. https://doi.org/10.1116/1.590438

Chan-Park MB, Neo WK (2003) Ultraviolet embossing for patterning high aspect ratio polymeric microstructures. Microsyst Technol 9(6–7):501–506. https://doi.org/10.1007/s00542-002-0289-0

Ahn S, Cha J, Myung H, Kim S, Kang S (2006) Continuous ultraviolet roll nanoimprinting process for replicating large-scale nano- and micropatterns. App Phys Lett 89(21):213101. https://aip.scitation.org/doi/10.1063/1.2392960

Yang JC, Huang CC (2013) Fabrication of dual brightness enhancement structures on light guide plates using UV roll-to-plate imprinting lithography. Optik - International Journal for Light and Electron Optics 124(18):3324–3328. https://doi.org/10.1016/j.ijleo.2012.10.049

Zhong ZW, Shan XC (2014) A study of meniscus formation and its effect on roll-to-roll UV embossing. Int J Eng Sci 85:10–19. https://doi.org/10.1016/j.ijengsci.2014.07.003

Du Y, Jochem KS, Thakral N, McCormick AV, Francis LF (2021) Roll-to-roll micromolding of UV curable coatings. J Coat Technol Res 18(3):627–639. https://doi.org/10.1007/s11998-021-00467-z

Kiatcharoenpol T, Vichiraprasert T (2018) Optimizing and modeling for plastic injection molding process using Taguchi method, Journal of Physics: Conference Series 1026(1):012018. https://iopscience.iop.org/article/10.1088/1742-6596/1026/1/012018.

Abdul R, Guo G, Chen JC, Yoo JJW (2020) Shrinkage prediction of injection molded high density polyethylene parts with Taguchi/artificial neural network hybrid experimental design. International Journal on Interactive Design and Manufacturing (IJIDeM) 14(2):345–357. https://doi.org/10.1007/s12008-019-00593-4

Wu CH, Chen WS (2006) Injection molding and injection compression molding of three-beam grating of DVD pickup lens, Sensors & Actuators: A Physical 125(2):367–375. https://doi.org/10.1016/j.sna.2005.07.025

Lee H, Lee JW, Hong IK, Lee S (2014) Optimal two-stage single-screw design for polymethyl methacrylate extrusion by Taguchi technique. J Ind Eng Chem 20(3):1119–1125. https://doi.org/10.1016/j.jiec.2013.06.050

Chen WC, Lai TT, Wang MW, Hung HW (2011) An optimization system for LED lens design. Expert Syst Appl 38(9):11976–11983. https://doi.org/10.1016/j.eswa.2011.03.092

Chen JC, Guo G, Wang WN (2020) Artificial neural network-based online defect detection system with in-mold temperature and pressure sensors for high precision injection molding. Int J Adv Manuf Technol 110(7–8):2023–2033. https://doi.org/10.1007/s00170-020-06011-4

Li K, Yan S, Pan W, Zhao G (2017) Warpage optimization of fiber-reinforced composite injection molding by combining back propagation neural network and genetic algorithm. Int J Adv Manuf Technol 90(1–4):963–970. https://link.springer.com/article/10.1007%2Fs00170-016-9409-3

Wang MW, Lin WC, Lee MH (2013) Optimal design and fabrication of a light guide film with roll to roll process. Microsyst Technol 19(11):1753–1759. https://doi.org/10.1007/s00542-013-1900-2

Kennedy J, Eberhart R (1995) Particle swarm optimization. Proceedings of ICNN'95 - International Conference on Neural Networks 4:1942–1948. https://doi.org/10.1109/ICNN.1995.488968.

Storn R, Price K (1997) Differential evolution – a simple and efficient heuristic for global optimization over continuous spaces. J Glob Optim 11:341–359. https://doi.org/10.1023/A:1008202821328

Funding

This work was supported by the Ministry of Science and Technology of Taiwan (MOST 107–2221-E-992–048).

Author information

Authors and Affiliations

Contributions

Conceptualization: Meng-Ting Wu and Cheng-Hsien Wu; methodology: Meng-Ting Wu, Ming-You Wu, and Cheng-Hsien Wu; optimization: Meng-Ting Wu and Ming-You Wu; experiment: Ming-You Wu and Cheng-Hsien Wu; resources: Cheng-Hsien Wu; writing. Meng-Ting Wu.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wu, MT., Wu, MY. & Wu, CH. Deep learning-based optimization using a limited number of experiments for roll-to-roll UV embossing. Int J Adv Manuf Technol 120, 5955–5967 (2022). https://doi.org/10.1007/s00170-022-09115-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09115-1