Abstract

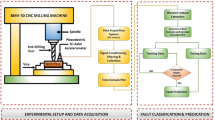

The reliability of machine tools is highly influenced by the cutting state. The traditional recognition method of cutting state is emphasized on a single classifier, which has the weakness of low identification accuracy and strong randomness. This paper proposes a cutting-state identification method based on improved Dempster-Shafer (DS) evidence theory. This method is divided into multi-classifier preliminary-diagnosis layer and improved DS information-fusion layer. The wavelet packet analysis method is extracted as the input of multi-classifier (Back Propagation (BP) neural network, genetic algorithm (GA) optimized BP neural network and thinking evolution (mind evolutionary algorithms) MEA optimized BP neural network). After the preliminary judgment, the improved DS information-fusion method is integrated as the final judgment, and finally, the effectiveness and feasibility of the method are verified.

Similar content being viewed by others

Availability of data and material

Not applicable.

Code availability

Not applicable.

References

Tong R, Liu Q (2015) Chatter recognition and suppression system of NC machining. Modul Mach Tool Autom Manuf Techn 2:117–121

Xie F, Cao Q, Huang Z (2015) Chatter monitoring based on wavelet packet and BP neural network. Instrum Techn Sensor 10:88–90

Li R, Liu Q (2015) Chatter identification in CNC milling based on wallet packet and Hilbert-Huang transform. Comput Integr Manuf Syst 21(1):204–216

Tangjitsitcharoen S, Moriwaki T (2008) Intelligent monitoring and identification of cutting states of chips and chatter on CNC turning machine. J Manuf Process 10(1):40–46

Gao HN, Shen DH, Yu L et al (2020) Identification of cutting chatter through deep learning and classification. Int J Simul Model 19(4):667–677

Xie F, Jiang W et al (2018) Cutting chatter recognition based on generalized BP neural network. JShock Vib 37(5):65–70

Gaoa X, Jiang P, Xie W et al (2021) Decision fusion method for fault diagnosis based on closeness and Dempster-Shafer theory. J Intell Fuzzy Syst 6:1–10

Hui HK, Lim MH, Leong S (2017) Dempster-Shafer based sensor fusion approach for machinery fault diagnosis. In: Proceedings of the ASME 2017 Power Conference, Charlotte, North Carolina, USA

Hui KH, Ooi CS, Meng HL et al (2016) A hybrid artificial neural network with Dempster-Shafer theory for automated bearing fault diagnosis. J Vibroeng 18(7):4409–4418

Ren X, Chen L, Li DS et al (2019) Fault decision of computer numerical control machine system using grey clustering analysis and rough set theory. Adv Mech Eng 11(5):16–87

Wang EH, Bo W et al (2016) Chatter detection in end milling processes based on wavelet packet decomposition and singular spectrum analysis. Mach Tool Hydraul 44(17):191–199

Zhao G, Chen A, Lu G, Liu W (2020) Data fusion algorithm based on fuzzy sets and D-S theory of evidence. Tsinghua Sci Technol 25(1):12–19

Zhang H, Lu J, Tang X (2020) An improved DS evidence theory algorithm for conflict evidence. J Beijing Univ Aeronaut Astronaut 46(3):616–623

Zhang A, Cheng Q, Qi B, Tao Z et al (2021) A general approach for the machining quality evaluation of S-shaped specimen based on POS-SQP algorithm and Monte Carlo method. J Manuf Syst 60:553–568

Niu P, Cheng Q, Zhang C et al (2021) A novel method for machining accuracy reliability and failure sensitivity analysis for multi-axis machine tool. Int J Adv Manuf Technol 152:1–14

Niu P, Cheng Q, Liu Z et al (2021) A machining accuracy improvement approach for a horizontal machining center based on analysis of geometric error characteristics. Int J Adv Manuf Technol 112(9):2873–2887

Qi BB, Cheng Q, Li SL et al (2021) Precision loss of ball screw mechanism under sliding-rolling mixed motion behavior. J Cent South Univ 28(5):1357–1376

Cheng Q, Qi B, Liu Z et al (2019) An accuracy degradation analysis of ball screw mechanism considering time-varying motion and loading working conditions. Mech Mach Theory 134:1–23

Funding

The project is supported by Transformation Program of Scientific and Technological Achievements of HeBei Provence.” The production, integration, and application of the industrial robot” (19041827Z).

Author information

Authors and Affiliations

Contributions

A diagnosis method of cutting state of machine tools based on improved DS algorithm is proposed. By collecting the vibration information of the machine tools and using the DS classifier for information fusion diagnosis, the final machining state of the equipment is accurately judged. Compared with the traditional single classifier, this method greatly improved the reliability of diagnosis.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xu, B., Sun, Y. Cutting-state identification of machine tools based on improved Dempster-Shafer evidence theory. Int J Adv Manuf Technol 124, 4099–4106 (2023). https://doi.org/10.1007/s00170-022-09056-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09056-9