Abstract

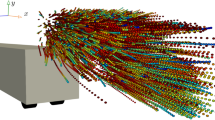

Recently, mass finishing processes have attracted renewed interests due to their feasibility on complex and rough additively manufactured components. In mass finishing, media sliding velocity (V) is a key parameter that directly influences material removal rate from a component. Experimental measurements of V are crucial in validating simulation models and improving fundamental process understanding. Thus far, measurement attempts have been conducted externally — with the image acquisition system located outside of the mass finishing bowl. In this work, a submersible media tracker is developed for internal V measurements within a stream finishing bowl. The velocity estimation results from two data post-processing methods are compared: (i) manual frame-by-frame tracking and (ii) particle image velocimetry (PIV). It is shown that with an appropriate evaluation frame rate, internal measurements could reliably estimate local media velocities at various locations within the stream finishing bowl. Media sliding velocities are most sensitive to changes in relative media approach angle in stream finishing. The velocity measurement results aid in fundamental process understanding and are useful in validating process simulation models.

Similar content being viewed by others

Availability of data and material

Not applicable.

Code availability

Not applicable.

References

Li WH, Yang SQ, Li XH, Li WD (2014) Development status and trends of mass finishing processes. Key Eng Mater 621:111–120

Boschetto A, Bottini L, Macera L, Veniali F (2020) Post-processing of complex SLM parts by barrel finishing. Appl Sci

Domblesky J, Evans R, Cariapa V (2004) Material removal model for vibratory finishing. Int J Prod Res 42(5):1029–1041

Uhlmann E, Eulitz A, Dethlefs A (2015) Discrete element modelling of drag finishing. Procedia CIRP 31:369–374

Hashimoto F, Chaudhari RG, Melkote SN (2016) Characteristics and performance of surfaces created by various finishing methods ( Invited Paper ). Procedia CIRP 45:1–6

Zanger F, Kacaras A, Neuenfeldt P, Schulze V (2019) Optimization of the stream finishing process for mechanical surface treatment by numerical and experimental process analysis. CIRP Ann 68(1):373–376

Hashimoto Y, Ito T, Nakayama Y, Furumoto T, Hosokawa A (2021) Fundamental investigation of gyro finishing experimental investigation of contact force between cylindrical workpiece and abrasive media under dry condition. Precis Eng 67:123–136

Yabuki A, Baghbanan MR, Spelt JK (2002) Contact forces and mechanisms in a vibratory finisher. Wear 252:635–643

Ciampini D, Papini M, Spelt JK (2007) Impact velocity measurement of media in a vibratory finisher. J Mater Process Technol 183(2–3):347–357

Hashemnia K, Spelt JK (2014) Particle impact velocities in a vibrationally fluidized granular flow: measurements and discrete element predictions. Chem Eng Sci 109:123–135

Cariapa V, Park H, Kim J, Cheng C, Evaristo A (2008) Development of a metal removal model using spherical ceramic media in a centrifugal disk mass finishing machine. Int J Adv Manuf Technol 39(1–2):92–106

Hashemnia K, Mohajerani A, Spelt JK (2013) Development of a laser displacement probe to measure particle impact velocities in vibrationally fluidized granular flows. Powder Technol 235:940–952

Pandiyan V, Castagne S, Subbiah S (2016) High frequency and amplitude effects in vibratory media finishing. Procedia Manuf 5:546–557

Fleischhauer E, Azimi F, Tkacik P, Keanini R, Mullany B (2016) Application of particle image velocimetry (PIV) to vibrational finishing. J Mater Process Technol 229:322–328

Zhang C, Liu W, Wang S, Liu Z, Morgan M, Liu X (2020) Dynamic modeling and trajectory measurement on vibratory finishing. Int J Adv Manuf Technol 106(1–2):253–263

Schulze V, Gibmeier J, Kacaras A (2017) Qualification of the stream finishing process for surface modification. CIRP Ann Manuf Technol 66(1):523–526

Mullany B et al (2017) The application of computational fluid dynamics to vibratory finishing processes. CIRP Ann Manuf Technol 66(1):309–312

Preston FW (1927) The theory and design of plate glass polishing machines. J Glass Technol 11:214

Funding

This research is supported by the A*STAR Industry Alignment Fund – Advanced Post-processing and Non-Destructive Evaluation for Additive Manufacturing (IAF-PP, Grant no. A20F9a0045).

Author information

Authors and Affiliations

Contributions

Kai Liang Tan: conceptualisation, methodology, writing — original draft, formal analysis, visualisation; Eng Tiong Neo: methodology, investigation, writing — original draft, software, validation; Joseph Lifton John: validation, writing — review and edit; Wei Shin Cheng: investigation, methodology; Sho Itoh: conceptualisation, funding acquisition, methodology.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tan, K.L., Neoh, E.T., Lifton, J.J. et al. Internal measurement of media sliding velocity in a stream finishing bowl. Int J Adv Manuf Technol 120, 4681–4691 (2022). https://doi.org/10.1007/s00170-022-09053-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09053-y