Abstract

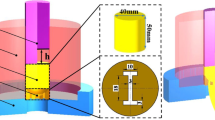

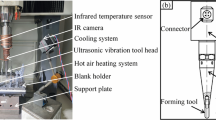

Due to the poor ductility of magnesium alloys at room temperature, many new forming methods are highly desired. This paper adopts the clustering ball spinning (CBS) method to form complex curved surfaces with the AZ31 magnesium alloy sheet. Firstly, the formula was built to analyze the stress components of the auxiliary forming (AF) region. Secondly, asymmetric forming was proposed and explored through numerical simulation and experiments. It is shown with a non-rotational symmetric workpiece that asymmetric forming can yield an increased geometric accuracy compared to symmetric forming (0.57-mm deviation from the target curved surface). Relation results show that complex curved surfaces with the AZ31 magnesium alloy sheet could be formed by CBS forming process at room temperature. The microstructure of curved surfaces was tested by electron backscattered scattering detection (EBSD), and it is demonstrated that the deformation of the AZ31 sheet by the CBS method is dominated initially by the extension twinning and non-basal slip system is activated with development of forming and the improvement of the temperature.

Similar content being viewed by others

Availability of data and materials

All data generated or analyzed during this study are included in this published article.

Code availability

Numerical simulation software is the property of the respective software houses. No other software developed for the data analysis is available.

Abbreviations

- CBS:

-

Clustering ball spinning

- AF:

-

Auxiliary forming region

- EBSD:

-

Electron backscattered scattering detection

- MLRB:

-

Multi-layer rigid ball

- FE:

-

Finite element

- RD:

-

Rolling direction

- TD:

-

Transverse direction

- IPF:

-

Inverse pole figure

References

Ren X, Huang Y, Zhang X, Li H, Zhao Y (2021) Influence of shear deformation during asymmetric rolling on the microstructure, texture, and mechanical properties of the AZ31B magnesium alloy sheet. Materials Science and Engineering a-Structural Materials Properties Microstructure and Processing 800. https://doi.org/10.1016/j.msea.2020.140306

Wen Y, Liu Q, Wang J, Yang Q, Zhao W, Qiao B, Li Y, Jiang D (2021) Improving in vitro and in vivo corrosion resistance and biocompatibility of Mg–1Zn–1Sn alloys by microalloying with Sr. Bioact Mater 6(12):4654–4669. https://doi.org/10.1016/j.bioactmat.2021.04.043

Du P, Furusawa S, Furushima T (2020) Microstructure and performance of biodegradable magnesium alloy tubes fabricated by local-heating-assisted dieless drawing. J Magnes Alloy 8(3):614–623. https://doi.org/10.1016/j.jma.2020.05.009

Ho YH, Man K, Joshi SS, Pantawane MV, Wu TC, Yang Y, Dahotre NB (2020) In-vitro biomineralization and biocompatibility of friction stir additively manufactured AZ31B magnesium alloy-hydroxyapatite composites. Bioact Mater 5(4):891–901. https://doi.org/10.1016/j.bioactmat.2020.06.009

Wenke B, Xingrong C, Shuxia L, Jun G (2015) Experimental investigation on formability and microstructure of AZ31B alloy in electropulse-assisted incremental forming. Mater Des 87:632–639. https://doi.org/10.1016/j.matdes.2015.08.072

Ambrogio G, Filice L, Manco GL (2008) Warm incremental forming of magnesium alloy AZ31. CIRP Ann 57(1):257–260. https://doi.org/10.1016/j.cirp.2008.03.066

Al-Samman T, Gottstein G (2008) Room temperature formability of a magnesium AZ31 alloy: examining the role of texture on the deformation mechanisms. Mater Sci Eng A 488(1–2):406–414. https://doi.org/10.1016/j.msea.2007.11.056

Agnew SR, Tomé CN, Brown DW, Holden TM, Vogel SC (2003) Study of slip mechanisms in a magnesium alloy by neutron diffraction and modeling. Scripta Mater 48(8):1003–1008. https://doi.org/10.1016/s1359-6462(02)00591-2

Duflou J, Tunckol Y, Szekeres A, Vanherck P (2007) Experimental study on force measurements for single point incremental forming. J Mater Process Technol 189(1–3):65–72. https://doi.org/10.1016/j.jmatprotec.2007.01.005

Durante M, Formisano A, Langella A, Capece MF, Memola, (2009) The influence of tool rotation on an incremental forming process. J Mater Process Technol 209(9):4621–4626. https://doi.org/10.1016/j.jmatprotec.2008.11.028

Jeswiet J, Micari F, Hirt G, Bramley A, Duflou J, Allwood J (2005) Asymmetric single point incremental forming of sheet metal. CIRP Ann 54(2):88–114. https://doi.org/10.1016/s0007-8506(07)60021-3

Wong CC, Dean TA, Lin J (2003) A review of spinning, shear forming and flow forming processes. Int J Mach Tools Manuf 43(14):1419–1435. https://doi.org/10.1016/s0890-6955(03)00172-x

Wu H, Xu W, Shan D, Jin BC (2019) Mechanism of increasing spinnability by multi-pass spinning forming – analysis of damage evolution using a modified GTN model. Int J Mech Sci 159:1–19. https://doi.org/10.1016/j.ijmecsci.2019.05.030

Hu ZQ, Guo CF, Li HM (2019) Influence of AZ31 sheet treated by cryogenic on punch shearing. J Cent South Univ 26(6):1582–1591. https://doi.org/10.1007/s11771-019-4114-7

Zhu C, Zhao S, Li S, Fan S (2018) Comparison of mandrel and counter-roller spinning methods for manufacturing large sheaves. Int J Adv Manuf Technol 100(1–4):409–419. https://doi.org/10.1007/s00170-018-2707-1

Zhiqing H, Jiaji L, Ge Y, Baojun L (2020) Study on numerical model with multi-layer rigid balls for fabricating curved surface based on clustering balls spinning method. Int J Precis Eng Manuf 21(8):1491–1499. https://doi.org/10.1007/s12541-020-00354-4

Silva MB, Skjoedt M, Martins PAF, Bay N (2008) Revisiting the fundamentals of single point incremental forming by means of membrane analysis. Int J Mach Tools Manuf 48(1):73–83. https://doi.org/10.1016/j.ijmachtools.2007.07.004

Chang Z, Chen J (2020) Investigations on the deformation mechanism of a novel three-sheet incremental forming. J Mater Process Technol 281:116619. https://doi.org/10.1016/j.jmatprotec.2020.116619

Funding

This work was supported by the National Natural Science Foundation of China (Grant No.51275201 and 51311130129) and the Jilin Province Key R&D Plan Project (Grant No.2014020462GX).

Author information

Authors and Affiliations

Contributions

Zhiqing Hu had the role of revision and paper writing. Lijia Da developed the concept of the paper and simulative work. Xincheng Li and Jia Xi were in charge of the development of the experimental work.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent to publication

All authors agree that the manuscript is published.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hu, Z., Da, L., Li, X. et al. Evaluation on forming process of AZ31 alloy complex curved surfaces by clustering balls spinning method. Int J Adv Manuf Technol 120, 6301–6313 (2022). https://doi.org/10.1007/s00170-022-09011-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09011-8