Abstract

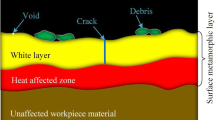

The discharge current waveform affects the processing characteristics and surface integrity by affecting the process of energy input. At present, although the rectangular current waveform is widely used in electrical discharge machining (EDM), there is not enough evidence to prove that it is the most suitable. Therefore, in this study, the influence of the discharge current waveforms on processing characteristics and surface integrity was investigated and compared under similar pulse energy. Three types of discharge current waveforms including rectangular (Rec), triangular (Tri), and trapezoidal (Tra) are used for processing. The material removal amount, surface topography, roughness, phase compositions, white layer thickness, and residual stress were investigated and analyzed. The results showed that Tri could remove the most materials per pulse-on duration, followed by Tra. Compared with Rec, the size of craters and debris on the sample surface produced by the Tri and Tra was larger. The surface roughness and residual stress of samples processed by Tri were the highest. When the discharge current waveform was constant, XRD spectra of samples fabricated by EDM under different pulse energy were almost the same. Compared with Rec, the diffraction peaks of samples produced by Tri and Tra were reduced. When the pulse energy was low, the white layer of samples processed by Rec was thinner than that processed by Tri. This phenomenon was reversed when the pulse energy was high. The white layer thickness of the sample fabricated by Tra was between the samples processed by Rec and Tri regardless of pulse energy.

Similar content being viewed by others

Availability of data and materials

All the data and materials of this work are available to the readers, according to the magazine policies.

References

Xu C, Liu Z, Zhang K, Han Y, Qiu M (2020) Composition analysis of discharge and combustion during the atomization EDM ablation. Int J Adv Manuf Tech 106:3475–3483. https://doi.org/10.1007/s00170-019-04773-0

Kumar A, Mandal A, Dixit AR, Mandal DK (2020) Quantitative analysis of bubble size and electrodes gap at different dielectric conditions in powder mixed EDM process[J]. Int J Adv Manuf Tech 107:3065–3075. https://doi.org/10.1007/s00170-020-05189-x

Shahri HRF, Mahdavinejad R, Ashjaee M, Abdullah A (2017) A comparative investigation on temperature distribution in electric discharge machining process through analytical, numerical and experimental methods. Int J Mach Tool Manu 114:35–53. https://doi.org/10.1016/j.ijmachtools.2016.12.005

Ekmekci B, Elkoca O, Erden A (2005) A comparative study on the surface integrity of plastic mold steel due to electric discharge machining. Metall Mater Trans B 36(1):117–124. https://doi.org/10.1007/s11663-005-0011-6

Khosrozadeh B, Shabgard M (2017) Effects of hybrid electrical discharge machining processes on surface integrity and residual stresses of Ti-6Al-4V titanium alloy. Int J Adv Manuf Tech 93(8):1–13. https://doi.org/10.1007/s00170-017-0601-x

Yue X, Yang X (2021) The role of discharge plasma on molten pool dynamics in EDM. J Mater Process Tech 117092:1–14. https://doi.org/10.1016/j.jmatprotec.2021.117092

Wang G, Han F (2021) A comparative study on the surface integrity of single-step and multi-step sequential machining in electric discharge machining. Int J Adv Manuf Tech 114:1803–1817. https://doi.org/10.1007/s00170-021-06947-1

Rajhi W, Alatawi I, Subhani T, Ayadi B, Al-Ghamdi A, Khaliq A (2021) A contribution to numerical prediction of surface damage and residual stresses on die-sinking EDM of Ti6Al4V. J Manuf Processes 68:1458–1484. https://doi.org/10.1016/j.jmapro.2021.06.056

Ali A, Pramanik A, Basak AK, Guy L (2018) Accuracy of duplex stainless steel feature generated by electrical discharge machining (EDM). Measurement 130:137–144. https://doi.org/10.1016/j.measurement.2018.08.013

Zeilmann RP, Bordin FM, Vacaro T (2015) Surface integrity of electrodischarge machined cavities for different depths and radii. J Braz Soc Mech Sci 37(1):93–104. https://doi.org/10.1007/s40430-014-0159-6

Lim LC, Lee LC, Wong YS, LHH (1991) Solidification microstructure of electro-discharge machined surfaces of tool steels. Mater Sci Technol 7(3):239–248. https://doi.org/10.1179/026708391790183411

Ekmekci B (2009) White Layer Composition, Heat Treatment, and Crack Formation in Electric Discharge Machining Process. Metall Mater Trans B 40(1):70–81. https://doi.org/10.1007/s11663-008-9220-0

Ekmekci B (2007) Residual stresses and white layer in electric discharge machining (EDM). Appl Surf Sci 253(23):9234–9240. https://doi.org/10.1016/j.apsusc.2007.05.078

Ghanem F, Sidhom H, Braham C, Fitzpatrick ME (2002) Effect of near-surface residual stress and microstructure modification from machining on the fatigue endurance of a tool steel. J Mater Eng Perform 11(6):631–639. https://doi.org/10.1361/105994902770343629

Lee HT, Tai TY (2003) Relationship between EDM parameters and surface crack formation. J Mater Process Tech 142:676–683. https://doi.org/10.1016/S0924-0136(03)00688-5

Tang J, Yang X (2018) Simulation investigation of thermal phase transformation and residual stress in single pulse EDM of Ti-6Al-4V. J Phys D Appl Phys 51(13):1–12. https://doi.org/10.1088/1361-6463/aab1a8

KiyakaO M, Çakır O (2007) Examination of machining parameters on surface roughness in EDM of tool steel. J Mater Process Tech 191(1–3):141–144. https://doi.org/10.1016/j.jmatprotec.2007.03.008

Lee HT, Hsu FC, Tai TY (2004) Study of surface integrity using the small area EDM process with a copper-tungsten electrode. Mat Sci Eng A Struct 364:346–356. https://doi.org/10.1016/j.msea.2003.08.046

Amorim FL, Weingaertner WL (2004) The influence of generator actuation mode and process parameters on the performance of finish EDM of a tool steel. J Mater Process Tech 166(3):411–416. https://doi.org/10.1016/j.jmatprotec.2004.08.026

Ishikawa A, Kunieda M (2019) Influence of current waveforms on single discharge crater in EDM. J Jpn Soc Precis Eng 85:717–721. https://doi.org/10.2493/jjspe.85.717

Han F, Jiang J, Yu D (2007) Influence of discharge current on machined surfaces by thermo-analysis in finish cut of WEDM. Int J Mach Tool Manu 47:1187–1196. https://doi.org/10.1016/j.ijmachtools.2006.08.024

Li XS, Cai AH, Zeng JJ (2012) Effect of EDM conditions on surface residual stress of Cr12MoV steel. Mater Sci Forum 697:171–175. https://doi.org/10.4028/www.scientific.net/MSF.697-698.171

Tzeng Y, Chen F (2005) Investigation into some surface characteristics of electrical discharge machined SKD-11 using powder-suspension dielectric oil. J Mater Process Techn 170:385–391. https://doi.org/10.1016/j.jmatprotec.2005.06.006

Nguyen TD, Nguyen PH, Banh LT (2019) Die steel surface layer quality improvement in titanium μ-powder mixed die sinking electrical discharge machining. Int J Adv Manuf Tech 100:2637–2651. https://doi.org/10.1007/s00170-018-2887-8

Sidhu SS, Batish A, Kumar S (2015) Analysis of residual stresses in particulate reinforced aluminium matrix composite after EDM. Mater Sci Tech 31(15):1850–1859. https://doi.org/10.1007/s00170-018-2887-8

Xia H, Hashimoto H, Kunieda M, Nishiwaki N (1996) Measurement of energy distribution in continuous EDM process. J Jpn Soc Precis Eng 62:1141–1145. https://doi.org/10.2493/jjspe.62.1141

Shabgard M, Ahmadi R, Seyedzavvar M, Oliaei SN (2013) Mathematical and numerical modeling of the effect of input-parameters on the flushing efficiency of plasma channel in EDM process. Int J Mach Tool Manu 65(2013):79–87. https://doi.org/10.1016/j.ijmachtools.2012.10.004

Zhang M, Zhang Q, Dou L, Liu Q, Dong C (2016) Comparisons of single pulse discharge crater geometries in EDM and EAM. J Manuf Process 22:74–81. https://doi.org/10.1016/j.jmapro.2016.01.013

Lin YC, Lee HS (2008) Machining characteristics of magnetic force-assisted EDM. Int J Machine Tool Manu 48(11):1179–1186. https://doi.org/10.1016/j.ijmachtools.2008.04.004

Tanaka K (2018) X-ray measurement of triaxial residual stress on machined surfaces by the cosα method using a two-dimensional detector. J Appl Crystallogr 51:1329–1338. 1107/S1600576718011056

Liu Y, Li X, Bai F, Wang Y, Liu N (2014) Effect of system parameters on the size distributions of hollow nickel microspheres produced by an ultrasound-aided electrical discharge machining process. Particuology 17:36–41. https://doi.org/10.1016/j.partic.2013.11.002

Wang G, Han F, Zhu L (2021) Evolution of white layer and residual stress in electrical discharge machining. proceedings of the ASME 2021 16th International Manufacturing Science and Engineering Conference. https://doi.org/10.1115/MSEC2021-63573

Funding

The authors would like to acknowledge the National Key Foundation of China (61409230307) and the National Key R&D Program of China (2018YFB1105900).

Author information

Authors and Affiliations

Contributions

Guisen Wang: conceptualization, methodology, experiment, validation, formal analysis, investigation, data curation, writing—original draft preparation, writing—review and editing; Fuzhu Han: supervision, project administration, funding acquisition. Liang Zhu: conceptualization, formal analysis, supervision.

Corresponding author

Ethics declarations

Ethical approval

The authors claim that there are no ethical issues involved in this research.

Consent to participate

All the authors consent to participate in this research and contribute to the research.

Consent to publish

All the authors consent to publish the research. There are no potential copyright/plagiarism issues involved in this research.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, G., Han, F. & Zhu, L. Experimental investigations on the influence of discharge current waveform on processing characteristics and surface integrity in electrical discharge machining. Int J Adv Manuf Technol 120, 3339–3351 (2022). https://doi.org/10.1007/s00170-022-08987-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-08987-7