Abstract

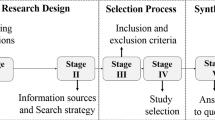

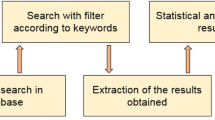

Given the dynamism of the markets and the economic growth, nowadays companies must look for mechanisms that allow them to develop new strategies and compete successfully. The objective of this work is to develop a statistical analysis of the complexity of a manufacturing system. The methodological approach starts with the analysis of the data obtained through the Likert technique, identifying characteristics associated with high complexity, consequently, an inquiry is made on the factors that influence significantly from an experimental analysis, then a factor analysis is made to determine the correlations between the variables raised, and finally the association between the complexity of the manufacturing characteristics and the complexity of the elements of a system is evaluated. The study is based on a sample of 71 small- and medium-sized companies in the city of Cartagena, Colombia. The results obtained show a dominance of complexity in manufacturing systems, confirming the level of significance between subsectors, type of operation, and type of process; determining that there are high correlations between the variables; and corroborating the relationship between the variables and the characteristics of the manufacturing system.

Similar content being viewed by others

References

Salom G, Shulterbrandt S (2012) Microenterprises, SMEs and Latin America. In Inter Forum Magazine. Retrieved on (pp. 10–12)

Wolff J, Pett T (2006) Small-firm performance: modeling the role of product and process improvements. J Small Bus Manag 44(2):268–284. https://doi.org/10.1111/j.1540-627X.2006.00167.x

Escobar A, Velandia G, Hernández P (2017) Gestión del conocimiento e innovación en las PYME exportadoras del sector industrial en Colombia

Pine Ii B, Hull R (1995) Mass customization: the new frontier in business competition. R and D Manag 25(2):254

Michalos G, Makris S, Papakostas N, Mourtzis D, Chryssolouris G (2010) Automotive assembly technologies review: challenges and outlook for a flexible and adaptive approach. CIRP J Manuf Sci Technol 2(2):81–91. https://doi.org/10.1016/j.cirpj.2009.12.001

Vidal GH, Hernández JRC (2021) Study of the effects of complexity on the manufacturing sector. Prod Eng Res Devel. https://doi.org/10.1007/s11740-020-01014-2

Papakostas N, Papachatzakis P, Xanthakis V, Mourtzis D, Chryssolouris G (2010) An approach to operational aircraft maintenance planning. Decis Support Syst 48(4):604–612. https://doi.org/10.1016/j.dss.2009.11.010

Herbert S (1962) The architecture of complexity. Proc Am Philos Soc 106(6):467–482. https://doi.org/10.2307/985254

Flynn B, Flynn E (1999) Information-processing alternatives for coping with manufacturing environment complexity. Decis Sci 30(4):1021–1052. https://doi.org/10.1111/j.1540-5915.1999.tb00917.x

Calinescu A, Efstathiou J, Bermejo J, Schirn J (1997) Assessing decision-making and process complexity in a manufacturer through simulation. IFAC Proceedings Volumes 30(24):149–152

Isik F (2010) An entropy-based approach for measuring complexity in supply chains. Int J Prod Res 48(12):3681–3696. https://doi.org/10.1080/00207540902810593

Gaio L, Gino F, Zaninotto E (2002) I sistemi di produzione: manuale per la gestione operativa dell’impresa. Carocci

Bick W, Drexl-Wittbecker S (2008) Komplexität reduzieren: Konzept. Methoden. Praxis. LOG_X, Stuttgart

Salum L (2000) The cellular manufacturing layout problem. Int J Prod Res 38(5):1053–1069. https://doi.org/10.1080/002075400189013

Heragu S, Kusiak A (1988) Machine layout problem in flexible manufacturing systems. Oper Res 36(2):258–268

Meller R, Gau K (1996) The facility layout problem: recent and emerging trends and perspectives. J Manuf Syst 15(5):351–366. https://doi.org/10.1287/opre.36.2.258

Li S, Rao S, Ragu-Nathan T, Ragu-Nathan B (2005) Development and validation of a measurement instrument for studying supply chain management practices. J Oper Manag 23(6):618–641. https://doi.org/10.1016/j.jom.2005.01.002

Wu Y, Frizelle G, Ayral L, Marsein J, Van de Merwe E, Zhou D (2002) A simulation study on supply chain complexity in manufacturing industry. En Proceedings of the conference of the manufacturing complexity network. University of Cambridge. https://doi.org/10.1016/j.cirpj.2019.02.001

Jacobs M (2007) Product complexity: a definition and impacts on operations. Decision Line 38(5):6–12. https://doi.org/10.1016/j.cirpj.2019.02.001

Efthymiou K, Mourtzis D, Pagoropoulos A, Papakostas N, Chryssolouris G (2016) Manufacturing systems complexity analysis methods review. Int J Comput Integr Manuf 29(9):1025–1044. https://doi.org/10.1080/0951192X.2015.1130245

Hernández S, Fernández C, Baptista L (2014) Metodología de la investigación. Investigación cuantitativa (p 5)

Tamayo M (2004) El proceso de la investigación científica. Editorial Limusa

Guimaraes T, Martensson N, Stahre J, Igbaria M (1999) Empirically testing the impact of manufacturing system complexity on performance. Int J Oper Prod Manag. https://doi.org/10.1108/01443579910294228

Bozarth C, Warsing D, Flynn B, Flynn E (2009) The impact of supply chain complexity on manufacturing plant performance. J Oper Manag 27(1):78–93. https://doi.org/10.1016/j.jom.2008.07

Garbie I, Shikdar A (2010) Complexity level in industrial firms: case studies and implementation. En Proceedings of the 2010 international conference on industrial engineering and operations management (IEOM 2010). Dhaka, Bangladesh: International University of Bangladesh, p 9–10

Eckstein D, Goellner M, Blome C, Henke M (2015) The performance impact of supply chain agility and supply chain adaptability: the moderating effect of product complexity. Int J Prod Res 53(10):3028–3046. https://doi.org/10.1080/00207543.2014.970707

Kohr D, Budde L, Friedli T (2017) Identifying complexity drivers in discrete manufacturing and process industry. Procedia CIRP 63:52–57

Alshammari F, Yahya K, Haron Z (2020) A conceptual approach in developing a project manager’s skills framework (PMSF) for improving the performance of complex projects in Kuwait construction industry. En IOP Conference Series: Materials Science and Engineering. IOP Publishing, p 012007

Saraph J, Benson PG, Schroeder RG (1989) An instrument for measuring the critical factors of quality management. Decis Sci 20(4):810–829. https://doi.org/10.1111/j.1540-5915.1989.tb01421.x

Sekaran U, Bougie R (2016) Research methods for business: a skill building approach. John Wiley & Sons

Acknowledgements

Thanks are due to the 71 small- and medium-sized enterprises in the manufacturing sector of the city of Cartagena, Colombia, for their access to technical visits, compilation of information, and support for the implementation of the instrument. Likewise to the Fundación Universitaria Tecnológico Comfenalco (FUTC), Investigation Group Ciptec, Universidad de la Costa (CUC)—Colombia and to the Universidad Nacional Lomas de Zamora (UNLZ)—Argentina, for the support of its academic and scientific group.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

The authors hereby state that the present work is in compliance with the ethical standards.

Consent to participate

Not applicable.

Consent for publication

The manuscript has not been published before and is not being considered for publication elsewhere.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Vidal, G.H., Hernández, J.R.C., Minnaard, C. et al. Statistical analysis of manufacturing system complexity. Int J Adv Manuf Technol 120, 3427–3436 (2022). https://doi.org/10.1007/s00170-022-08981-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-08981-z