Abstract

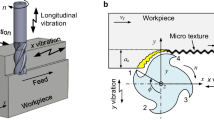

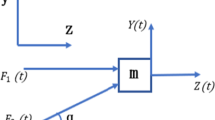

Elliptical ultrasonic vibration-assisted milling (EUVAM) adds high-frequency vibration to conventional milling (CM) to realize high-frequency intermittent milling. It has broad application prospects in the processing of difficult-to-cut materials such as titanium alloys, superalloys, and hard and brittle materials. To reveal the mechanism of the highly intermittent cutting nature in EUVAM, according to the motion relationship between the cutting edge and the workpiece and the Z-map representation of the workpiece, a method and its algorithm for calculating the undeformed cutting thickness and thus the cutting force in EUVAM are proposed. The simulation results show that EUVAM can improve the actual cutting speed when compared with CM, and the proportion of idle cutting time will directly determine the intermittent degree of the milling process. The experiment of EUVAM is performed to verify the correctness of the proposed cutting force model, and the impact of spindle speed on the cutting force in EUVAM is also analyzed. It is shown that UEVAM can reduce the cutting force by up to 50% under appropriate cutting conditions.

Similar content being viewed by others

Availability of data and material

The data used to support the findings of this study are included within the article.

References

Jin X, Xie B (2015) Experimental study on surface generation in vibration-assisted micro-milling of glass. Int J Adv Manuf Technol 81(1–4):507–512

Shamoto E, Moriwaki T (1999) Ultraprecision diamond cutting of hardened steel by applying elliptical vibration cutting. CIRP Ann 48(1):441–444

Xu W, Zhang LC, Wu Y (2014) Elliptic vibration-assisted cutting of fiber-reinforced polymer composites: understanding the material removal mechanisms. Compos Sci Technol 92:103–111

Sui H, Zhang X, Zhang D, Jiang X, Wu R (2017) Feasibility study of high-speed ultrasonic vibration cutting titanium alloy. J Mater Process Technol 247(19):111–120

Jung H, Hayasaka T, Shamoto E, Xu L (2020) Suppression of forced vibration due to chip segmentation in ultrasonic elliptical vibration cutting of titanium alloy Ti–6Al–4V. Precis Eng 64

Insperger T, Lehotzky D, Stepan G (2015) Regenerative delay parametric forcing and machine tool chatter: a review. IFAC-PapersOnLine 48(12):322–327

Altintas Y, Weck M (2004) Chatter stability of metal cutting and grinding. CIRP Ann 53(2):619–642

Xiao M, Karube S, Soutome T, Sato K (2002) Analysis of chatter suppression in vibration cutting. Int J Mach Tools Manuf 42(15):1677–1685

Ma C, Ma J, Shamoto E, Moriwaki T (2011) Analysis of regenerative chatter suppression with adding the ultrasonic elliptical vibration on the cutting tool. Precis Eng 35(2):329–338

Wan S, Jin X, Maroju NK, Hong J (2019) Effect of vibration assistance on chatter stability in milling. Int J Mach Tools Manuf 145:103432

Gao J, Altintas Y (2020) Chatter stability of synchronized elliptical vibration assisted milling. CIRP J Manuf Sci Technol 28:76–86

Muhammad R, Ahmed N, Deiral M, Roy A, Silberschmidt VV (2011) Computational study of ultrasonically-assisted turning of Ti alloys. Adv Mat Res 223:30–36

Tong J, Wei G (2019) Characteristics of cutting force during titanium alloy processed with UEVC. J Shock Vib 38(9):208–214

Liu J, Jiang X, Zhang G, Zhang M, Zhang D (2019) Investigation of the effect of vibration amplitude on the surface integrity in high-speed rotary ultrasonic elliptical machining for side milling of Ti-6Al-4V. J Mech Eng 55(11):215–223

Abootorabi Z, Razfar M, Abdullah A (2012) Investigation of the effect of cutting speed and vibration amplitude on cutting forces in ultrasonic-assisted milling. Proc Inst Mech Eng B J Eng Manuf 226(7):1185–1191

Han X, Zhang D (2020) Effects of separating characteristics in ultrasonic elliptical vibration-assisted milling on cutting force, chip, and surface morphologies. Int J Adv Manuf Technol 108:3075–3084

Lee SK, Ko SL (2002) Development of simulation system for machining process using enhanced Z map model. J Mater Process Technol 130(1):608–617

Li Z, Liu Q (2012) Z-map based surface machining accuracy in high-speed peripheral milling of flexible system. J Huazhong Univ Sci Technol Nat Sci 40:64–67

Li Z, Zhu L, Yang Z, Ma J, Cao W (2021) Investigation of tool-workpiece contact rate and milling force in elliptical ultrasonic vibration assisted milling. Int J Adv Manuf Technol 118:585–601

Gradisek J, Kalveram M, Weinert K (2004) Mechanistic identification of specific force coefficients for a general end mill. Int J Mach Tool Manuf 44(4):401–414

Funding

This research is financially supported by the Natural Science Foundation of Hunan Province (2020JJ4270).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, Z., Xiao, J., Han, X. et al. Z-map based cutting force prediction for elliptical ultrasonic vibration-assisted milling process. Int J Adv Manuf Technol 120, 3237–3249 (2022). https://doi.org/10.1007/s00170-022-08976-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-08976-w