Abstract

Metallic glass is an excellent material for optical, electromagnetic, and structural parts due to its high strength, high hardness, wear resistance, and corrosion resistance. But due to its high strength and high hardness, it is difficult to be machined, which hinders the further wide application of metallic glass in industry. Some research on traditional and non-traditional machining of metallic glass has been done in recent years. In traditional machining, the related research is mainly focused on machined surface quality, tool wear, and cutting force in turning, milling, and grinding of metallic glass. In non-traditional machining, related research is mainly conducted on machined surface quality and material removal rate by sinker electrical discharge machining (Sinker EDM) metallic glass. The relevant machinability of wire electrical discharge machining (WEDM) and wire electrochemical micro-machining (WECMM) metallic glass is also analyzed and elaborated. Meanwhile, some scholars have carried out study on the laser and ultrasonic welding machining. Based on the above statement, this paper mainly summarizes and analyzes the research progress and some results of traditional and non-traditional machining of metallic glass. Then the machining development trend of metallic glass and further application is discussed, which provides certain reference for furtherly improving machining precise and efficient of metallic glass.

Similar content being viewed by others

References

Sheng HW, Luo WK, Alamgir FM, Bai JM, Ma E (2006) Atomic packing and short-to-medium-range order in metallic glasses. Nature 439(7075):419–425. https://doi.org/10.1038/nature04421

Greer AL, Ma E (2007) Bulk metallic glasses: at the cutting edge of metals research. MRS Bull 32(8):611–615. https://doi.org/10.1557/mrs2007.121

Takeuchi A, Inoue A (2005) Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater Trans 46(12):2817–2829. https://doi.org/10.2320/matertrans.46.2817

Inoue A, Takeuchi A (2010) Recent development and application products of bulk glassy alloys. Acta Mater 59(6):273–295. https://doi.org/10.1016/j.actamat.2010.11.027

Yin J, Lei FJ, Tan HM (2016) Review on classification of bulk metallic glass. Hot Working Technology 45(14):9–13. https://doi.org/10.14158/j.cnki.1001-3814.2016.14.003

Zhang HF, Ding BZ, Hu ZQ (2001) Investigations and progresses on bulk metal glasses. Acta Metall Sin 37(11):1131–1141. https://doi.org/10.3321/j.issn:0412-1961.2001.11.002

Kokanovic I (2006) Effect of heat treatment on various physical properties in Zr80Ni20 metallic glass. Phys Status Solidi A 203(8):2029–2036. https://doi.org/10.1002/pssa.200522149

Wang WH (2009) Bulk metallic glasses with functional physical properties. Adv Mater 21(45):4524–4544. https://doi.org/10.1002/adma.200901053

Zhang JL, Shan GC, Li J, Wang YM, Shek CH (2018) Structures and physical properties of two magnetic Fe-based metallic glasses. J Alloy Compd 747:636–639. https://doi.org/10.1016/j.jallcom.2018.03.085

Trexler MM, Thadhani NN (2010) Mechanical properties of bulk metallic glasses. Prog Mater Sci 55(8):759–839. https://doi.org/10.1016/j.pmatsci.2010.04.002

Louzguine-Luzgin DV, Polkin VI (2017) Properties of bulk metallic glasses. Russ J Non-Ferr Met+ 58(1):80–92. https://doi.org/10.3103/S1067821217010084

Tang XC, Meng LY, Yao XH (2021) Damage evolution during the dynamic tensile fracture (spallation) of metallic glasses. Chin Sci Bull 66(15):1847–1860. https://doi.org/10.1360/TB-2020-0995

Wang WH, Dong C, Shek CH (2004) Bulk metallic glasses. Mat Sci Eng R 44(2–3):45–89. https://doi.org/10.1016/j.mser.2004.03.001

Axinte E (2012) Metallic glasses from “alchemy” to pure science: Present and future of design, processing and applications of glassy metals. Mater Desing 35:518–556. https://doi.org/10.1016/j.matdes.2011.09.028

Ismagilov FR, Papini L, Vavilov VE, Gusakov DV (2020) Design and performance of a high-speed permanent magnet generator with amorphous alloy magnetic core for aerospace applications. IEEE Trans Ind Electron 67(3):1750–1758. https://doi.org/10.1109/TIE.2019.2905806

Khan MM, Deen KM, Haider W (2019) Combinatorial development and assessment of a Zr-based metallic glass for prospective biomedical applications. J Non Cryst Solids 523:119544. https://doi.org/10.1016/j.jnoncrysol.2019.119544

Jabed A, Khan MM, Camiller J, Greenlee-Wacker M, Haider W, Shabib I (2019) Property optimization of Zr-Ti-X (X = Ag, Al) metallic glass via combinatorial development aimed at prospective biomedical application. Surf Coat Technol 372:278–287. https://doi.org/10.1016/j.surfcoat.2019.05.036

Xu GF (2017) Experimental study of wear morphology of mental glass (Vit1) cutting tool. Qinhuangdao: Yanshan University

Chen X, Xiao JF, Zhu Y, Tian RJ, Shu XW, Xu JF (2017) Micro-machinability of bulk metallic glass in ultra-precision cutting. Mater Des 136:1–12. https://doi.org/10.1016/j.matdes.2017.09.049

Fu JB (2018) Simulation and experimental study on the formation of burr in micro milling of metallic glass. Dissertation, Yanshan University

Burkov AA, Pyachin SA, Zaytsev AV, Syuy NA, Zaykov ER (2018) Wear resistance of Fe33Ni8Cr8W8Mo8Co8C16B11 metallic glass-based electrospark coatings. J Frict Wear 39(5):381–387. https://doi.org/10.3103/S1068366618050045

Lan XD, Wu H, Liu Y, Zhang WD, Li RD, Chen SQ, Zai XF, Hu T (2016) Microstructures and tribological properties of laser cladded Ti-based metallic glass composite coatings. Mater Charact 120:82–89. https://doi.org/10.1016/j.matchar.2016.08.026

Esmaeili A, Ghafarri SA, Nikkhah M, Ghaini FM, Farzan F, Mohammadi S (2020) Biocompatibility assessments of 316L stainless steel substrates coated by Fe-based bulk metallic glass through electro-spark deposition method. Colloids Surf B 198:111469. https://doi.org/10.1016/j.colsurfb.2020.111469

Liao ZR, La Monaca A, Murray J, Speidel A, Ushmaev D, Clare A, Axinte D, M’Saoubi R (2021) Surface integrity in metal machining-Part I: Fundamentals of surface characteristics and formation mechanisms. Int J Mach Tool Manu 162:103687. https://doi.org/10.1016/J.IJMACHTOOLS.2020.103687

Monaca AL, Murray JW, Liao ZR, Speidel A, Robles-Linares JA, Axinte DA, Hardy MC, Clare AT (2021) Surface integrity in metal machining-Part II: Functional performance. Int J Mach Tool Manu 164:103718. https://doi.org/10.1016/J.IJMACHTOOLS.2021.103718

Xu DD, Liao ZR, Axinte D, Hardy M (2020) A novel method to continuously map the surface integrity and cutting mechanism transition in various cutting conditions. Int J Mach Tool Manu 151:103529. https://doi.org/10.1016/j.ijmachtools.2020.103529

Zhu PZ, Qiu C, Fang FZ, Yuan DD, Shen XC (2014) Molecular dynamics simulations of nanometric cutting mechanisms of amorphous alloy. Appl Surf Sci 317:432–442. https://doi.org/10.1016/j.apsusc.2014.08.031

He GH, Li LX, Liu XL, Jiang T, Zou JP (2020) Study on the cutting characteristics and chip formation mechanism of typical amorphous alloy Fe40Ni40P14B6 under micro cutting conditions. J Mech Eng 56(3):223–232. https://doi.org/10.3901/JME.2020.03.223

Zhu PZ, Fang FZ (2014) On the mechanism of material removal in nanometric cutting of metallic glass. Appl Phys A-Mater 116(2):605–610. https://doi.org/10.1007/s00339-013-8189-y

Avila KE, Kuchemann S, Alhafez IA, Urbassek HM (2020) An atomistic study of shear-band formation during cutting of metallic glasses. J Appl Phys 127(11):115101. https://doi.org/10.1063/1.5141336

Avila KE, Vardanyan VH, Alhafez IA, Zimmermann M, Kirsch B, Urbassek HM (2020) Applicability of cutting theory to nanocutting of metallic glasses: Atomistic simulation. J Non-Cryst Solids 550:120363. https://doi.org/10.1016/j.jnoncrysol.2020.120363

Avila KE, Kuchemann S, Urbassek HM (2021) Interaction between parallel shear bands in a metallic glass. J Non-Cryst Solids 566:120882. https://doi.org/10.1016/j.jnoncrysol.2021.120882

Wu CD, Fang TH, Su JK (2017) Nanometric mechanical cutting of metallic glass investigated using atomistic simulation. App Surf Sci 396:319–326. https://doi.org/10.1016/j.apsusc.2016.10.143

Liu Y, Gong YD, Sun Y, Zhang H (2018) Simulation of temperature field for bulk metallic glass in micro-scale grinding. J Northeast Univ 39(6):828–833. https://doi.org/10.12068/j.issn.1005-3026.2018.06.014

Bakkal M, Shih AJ, Scattergood RO (2004) Chip formation, cutting forces, and tool wear in turning of Zr-based bulk metallic glass. Int J Mach Tool Manu 44(9):915–925. https://doi.org/10.1016/j.ijmachtools.2004.02.002

Jiang MQ, Dai LH (2009) Formation mechanism of lamellar chips during machining of bulk metallic glass. Acta Mater 57(9):2730–2738. https://doi.org/10.1016/j.actamat.2009.02.031

Huang H, Zhao HW, Shi CL, Wu BD, Fan ZQ, Wan SG, Geng CY (2012) Effect of residual chips on the material removal process of the bulk metallic glass studied by in situ scratch testing inside the scanning electron microscope. AIP Adv 2(4):042193. https://doi.org/10.1063/1.4774032

Ding F, Wang CY, Zhang T, Zheng LJ, Zhu XG (2018) High performance cutting of Zr-based bulk metallic glass: a review of chip formation. Procedia CIRP 77:421–424. https://doi.org/10.1016/j.procir.2018.08.294

Bakkal M, Liu CT, Watkins TR, Scattergood RO, Shih AJ (2003) Oxidation and crystallization of Zr-based bulk metallic glass due to machining. Intermetallics 12(2):195–204. https://doi.org/10.1016/j.intermet.2003.09.017

Bakkal M (2009) Electron microscopy of bulk metallic glass machining chips. J Non-Cryst Solids 355(45–47):2220–2223. https://doi.org/10.1016/j.jnoncrysol.2009.07.018

Li XY (2019) Study on cutting forces, chip morphology, tool wear of amorphous alloy in orthogonal free cutting. Dissertation, Yanshan University. https://doi.org/10.27440/d.cnki.gysdu.2019.000589

Chong FF, To S, Chan KC (2012) Cutting characteristics of lanthanum base metallic glass in single point diamond turning. Key Eng Mater 516:651–655. https://doi.org/10.4028/www.scientific.net/KEM.516.651

Han DX, Wang G, Li J, Chan KC, To S, Wu FF, Gao YL, Zhai QJ (2015) Cutting characteristics of Zr-based bulk metallic glass. J Mater Sci Technol 31(2):153–158. https://doi.org/10.1016/j.jmst.2014.11.010

Xiong J, Wang H, Zhang GQ, Chen YB, Ma J, Mo RD (2019) Machinability and surface generation of Pd40Ni10Cu30P20 bulk metallic glass in single-point diamond turning. Micromachines 11(1):4. https://doi.org/10.3390/mi11010004

Sakata S, Hayashi A, Terajima T, Nakao Y (2016) Influence of cutting condition on surface roughness in single point diamond turning of Zr-based bulk metallic glass. ASME International Mechanical Engineering Congress and Exposition 2. https://doi.org/10.1115/IMECE2016-66289

Zhang WG (2012) Cutting property of Vit1 bulk metallic glasses. Qinhuangdao: Yanshan University

Fujita K, Morishita Y, Nishiyama N, Kimura H, Inoue A (2005) Cutting characteristics of bulk metallic glass. Mater Tran 46(12):2856–2863. https://doi.org/10.2320/matertrans.46.2856

Bakkal M, Naksiler V (2009) Cutting mechanics of bulk metallic glass materials on meso-end milling. Mater Manuf Process 24(12):1249–1255. https://doi.org/10.1080/10426910903129711

Ray D, Puri AB, Hanumaiah N (2019) An experimental investigation on the formation of burrs in micro milling of Zr-based amorphous bulk metallic glass. Int J Mater Prod Tec 59(2):140–171. https://doi.org/10.1504/IJMPT.2019.102633

Wang T, Wu XY, Zhang GQ, Chen YH, Xu B, Ruan SC (2020) Study on surface roughness and top burr of micro-milled Zr-based bulk metallic glass in shear dominant zone. Int J Adv Manuf Technol 107(9–10):4287–4299. https://doi.org/10.1007/s00170-020-05325-7

Wang JC, Zhang ZH, Zhang C, Fu JB, Chen JC (2020) Simulation and experiment study of burrs in micro-milling Zr-based metallic glass. J Mech Sci Technol 34(7):3027–3039. https://doi.org/10.1007/s12206-020-0634-1

Xie BY, Kumar MN, Yan DP, Jin XL (2017) Material behavior in micro milling of zirconium based bulk metallic glass. Miner Met Mater Ser Springer Cham pp. 363–373. https://doi.org/10.1007/978-3-319-51493-2_34

Wang ZY, Wang P, Fu JB (2020) Experimental study on surface roughness in micro-milling of Vit1 bulk metallic glasses. Modern Manufacturing Engineering (4):23–26. https://doi.org/10.16731/j.cnki.1671-3133.2020.04.005

Ray D, Puri AB, Hanumaiah N (2020) Experimental analysis on the quality aspects of micro-channels in mechanical micro milling of Zr-based bulk metallic glass. Measurement 158:107622. https://doi.org/10.1016/j.measurement.2020.107622

Wang T, Wu XY, Zhang GQ, Xu B, Chen YH, Ruan SC (2020) Experimental study on machinability of Zr-based bulk metallic glass during micro milling. Micromachines 11(1):86. https://doi.org/10.3390/mi11010086

Maroju NK, Yan DP, Xie BY, Jin XL (2018) Investigations on surface microstructure in high-speed milling of Zr-based bulk metallic glass. J Manuf Process 35:40–50. https://doi.org/10.1016/j.jmapro.2018.07.020

Bakkal M, Naksiler V, Derin B (2010) Machinability of bulk metallic glass materials on milling and drilling. Adv Mat Res 83–86:335–341. https://doi.org/10.4028/www.scientific.net/AMR.83-86.335

Ray D, Puri AB, Nagahanumaiah (2019) Investigation on cutting forces and surface finish in mechanical micro milling of Zr-based bulk metallic glass. J Adv Manuf Syst 18(1):113–132. https://doi.org/10.1142/S0219686719500069

Fang ZL, Nakao M (2020) Local magnetic deterioration on work-hardening layer of FeSiB metallic glass by milling. Cirp Ann-Manuf Techn 69(1):501–504. https://doi.org/10.1016/j.cirp.2020.04.009

Serbest E, Bakkal M, Karipcin I, Derin B (2011) The effect of cutting speed in metallic glass grinding. AIP Conf Proc 1315:967–927. https://doi.org/10.1063/1.3552578

Bakkal M, Serbest E, Karipçin I, Kuzu AT, Karagüzel U, Derin B (2015) An experimental study on grinding of Zr-based bulk metallic glass. Adv Manuf 3(4):282–291. https://doi.org/10.1007/s40436-015-0121-6

Liu Y, Gong YD, Sun Y, Zhang H, Li Q (2018) Microgrinding characteristics of Zr-based bulk metallic glasses. Int J Adv Manuf Technol 94(5–8):2401–2417. https://doi.org/10.1007/s00170-017-0986-6

Zhang FL, Huang GW, Liu JM, Du ZJ, Wu SX, Wang CY (2021) Grinding performance and wear of metal bond super-abrasive tools in grinding of Zr-based bulk metallic glass. Int J Refract Met H 97:105501. https://doi.org/10.1016/j.ijrmhm.2021.105501

Gong YD, Liu Y, Sun YW, XL, Li Q, Qu SS, Cai M (2018) Experimental and emulational investigations into grinding characteristics of Zr-based bulk metallic glass (BMG) using microgrinding. Int J Adv Manuf Technol 97(9–12):3431–3451. https://doi.org/10.1007/s00170-018-2212-6

Yeo SH, Tan PC, Aligiri E, Tor SB, Loh NH (2009) Processing of zirconium-based bulk metallic glass (BMG) using micro electrical discharge machining (Micro-EDM). Mater Manuf Process 24(12):1242–1248. https://doi.org/10.1080/10426910903129661

Hsieh SF, Chen SL, Lin MH, Ou SF, Lin WT, Huang MS (2013) Crystallization and carbonization of an electrical discharge machined Zr-based bulk metallic glass alloy. J Mater Res 28(22):3177–3184. https://doi.org/10.1557/jmr.2013.329

Huang H, Yan JW (2015) On the surface characteristics of a Zr-based bulk metallic glass processed by microelectrical discharge machining. Appl Surf Sci 355:1306–1315. https://doi.org/10.1016/j.apsusc.2015.08.239

Xu B, Wu XY, Ma J, Liang X, Lei JG, Wu B, Ruan SC, Wang ZL (2016) Micro-electrical discharge machining of 3D micro-molds from Pd40Cu30P20Ni10 metallic glass by using laminated 3D micro-electrodes. J Micromech Microeng 26(3):035004. https://doi.org/10.1088/0960-1317/26/3/035004

Liu C, Duong N, Jahan MP, Ma JF, Kirwin R (2019) Experimental investigation and numerical simulation of micro-EDM of bulk metallic glass with focus on crater sizes. Procedia Manuf 34:275–286. https://doi.org/10.1016/j.promfg.2019.06.151

Aliyu AA, Abdul-Rani AM, Ginta TL, Prakash C, Axinte E, Fua-Nizan R (2017) Investigation of nanoporosities fabricated on metallic glass surface by hydroxyapatite mixed EDM for orthopedic application. Mal J Fund Appl Sci 13:523–528. https://doi.org/10.11113/mjfas.v13n4-2.830

Liu JL, Zhu ZH, Yin L, Li XM, Zheng HJ (2012) Effect of wire saw technic on the soft magnetic properties of Fe78Si9B13 amorphous alloy under line frequency. J Nanchang Univ Nat Sci 36(4):351–354. https://doi.org/10.3969/j.issn.1006-0464.2012.04.010

Xu JK, Pei QQ, Lian ZX, Yu P, Ma GS, Yu HD (2019) Experimental study on wire-electrical discharge machining of zirconium-based metallic glass. Mater Res Express 6(11):115214. https://doi.org/10.1088/2053-1591/ab2773

Pei QQ, Xu JK, Lian ZX, Yu P, Ma GS, Yu HD (2019) Experimental study on wire-electrical discharge machining (WEDM) of zirconium-based metallic (MG) glass based on orthogonal test. 2019 IEEE International Conference on Manipulation, Manufacturing and Measurement on the Nanoscale (3M-NANO) pp. 16–19. https://doi.org/10.1109/3M-NANO46308.2019.8947372

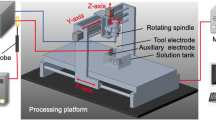

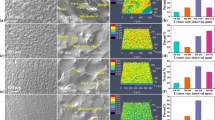

Meng LC, Zeng YB, Fang XL, Zhu D (2018) Micro-shaping of metallic glass by wire electrochemical micro-machining with a reciprocating traveling workpiece. J Alloys Compd 739:235–248. https://doi.org/10.1016/j.jallcom.2017.12.157

Meng LC, Zeng YB, Zhu D (2019) Wire electrochemical micromachining of Ni-based metallic glass using bipolar nanosecond pulses. Int J Mach Tool Manu 146:103439. https://doi.org/10.1016/j.ijmachtools.2019.103439

Meng LC, Zeng YB, Fang XL, Zhu D (2017) Micropatterning of Ni-based metallic glass by pulsed wire electrochemical micro machining. Intermetallics 81:16–25. https://doi.org/10.1016/j.intermet.2017.02.015

Yu Y, Meng LC, Zeng YB, Fang XL (2019) Study of electrochemical properties and processing by wire electrochemical micro-machining of Zr-based metallic glass. Electromachining & Mould 02:31–35. https://doi.org/10.3969/j.issn.1009-279X.2019.02.007

Meng LC, Zeng YB, Zhu D (2017) Investigation on wire electrochemical micro machining of Ni-based metallic glass. Electrochim Acta 233:274–283. https://doi.org/10.1016/j.electacta.2017.03.045

Hang YS, Zeng YB, Yang T, Meng LC (2020) The dissolution characteristics and wire electrochemical micromachining of metallic glass Ni82Cr7Si5Fe3B3. J Manuf Process 58:884–893. https://doi.org/10.1016/j.jmapro.2020.08.069

Kawahito Y, Terajima T, Kimura H, Kuroda T, Nakata K, Katayama S, Inoue A (2007) High-power fiber laser welding and its application to metallic glass Zr55Al10Ni5Cu30. Mater Sci Eng B 148(1–3):105–109. https://doi.org/10.1016/j.mseb.2007.09.062

Wang G, Huang YJ, Shagiev M, Shen J (2012) Laser welding of Ti40Zr25Ni3Cu12Be20 bulk metallic glass. Mater Sci Eng A 541:33–37. https://doi.org/10.1016/j.msea.2012.01.114

Wang HS, Su YZ, Jang JSC, Chen HG (2013) A comparison of crystallization behaviors of laser spot welded Zr-Cu-Ag-Al and Zr-Cu-Ni-Al bulk metallic glasses. Mater Chem Phys 139(1):215–219. https://doi.org/10.1016/j.matchemphys.2013.01.025

Li JF, Sun YH, Ding DW, Wang WH, Bai HY (2020) Nanosecond-pulsed laser welding of metallic glass. J Non Cryst Solids 537:120016. https://doi.org/10.1016/j.jnoncrysol.2020.120016

Chen B, Shi TL, Liao GL (2014) Laser welding of Zr41Ti14Cu12Ni10Be23 Bulk Metallic Glass and Zirconium Metal. J Wuhan Univ Technol Sci Ed 29(4):786–788. https://doi.org/10.1007/s11595-014-0997-1

Wang HS, Chiou MS, Chen HG, Jang JSC (2011) The effects of initial welding temperature and welding parameters on the crystallization behaviors of laser spot welded Zr-based bulk metallic glass. Mater Chem Phys 129(1–2):547–552. https://doi.org/10.1016/j.matchemphys.2011.04.067

Chen B, Shi TL, Li M, Yang F, Yan F, Liao GL (2014) Laser welding of annealed Zr55Cu30Ni5Al10 bulk metallic glass. Intermetallics 46:111–117. https://doi.org/10.1016/j.intermet.2013.11.008

Shen YY, Li YQ, Tsai HL (2019) Effect of pre-existing nuclei on crystallization during laser welding of Zr-based metallic glass. J Non Crys Solids 513:55–63. https://doi.org/10.1016/j.jnoncrysol.2019.03.022

Zhang YX, An LB (2018) Research progress on laser assisted machining. J Aeronaut Mater 38(2):77–85. https://doi.org/10.11868/j.issn.1005-5053.2017.000005

Park SS, Wei Y, Jin XL (2018) Direct laser assisted machining with a sapphire tool for bulk metallic glass. Cirp Ann-Manuf Techn 67(1):193–196. https://doi.org/10.1016/j.cirp.2018.04.070

Jin M, Zhao Y, Zhao GG, Fu JB, Wang JC (2019) Simulation research of laser-assisted machining of Vit1 metallic glass based on D-P constitutive model. Chin High Technol Lett 29(10):1003–1011. https://doi.org/10.3772/j.issn.1002-0470.2019.10.008

Gong QR (2019) Study of laser assisted micromachining mechanism of amorphous alloy. Harbin: Harbin Institute of Technology

Qiu P, Teraoka S, Gong QR, Xu SL, Shimada K, Mizutani M, Kuriyagawa T (2020) Surface defect inhibition mechanisms of laser assisted microcutting on Ni-P amorphous alloy. J Manuf Process 60:644–653. https://doi.org/10.1016/j.jmapro.2020.11.005

Ichitsubo T, Kai S, Ogi H, Hirao M, Tanaka K (2003) Elastic and anelastic behavior of Zr55Al10Ni5Cu30 bulk metallic glass around the glass transition temperature under ultrasonic excitation. Scr Mater 49(4):267–271. https://doi.org/10.1016/S1359-6462(03)00294-X

Ichitsubo T, Matsubara E, Chen HS, Saida J, Yamamoto T, Nishiyama N (2006) Structural instability of metallic glasses under radio-frequency-ultrasonic perturbation and its correlation with glass-to-crystal transition of less-stable metallic glasses. J Chem Phys 125(15):154502. https://doi.org/10.1063/1.2346672

Kim J (2014) Weldability of Cu54Zr22Ti18Ni6 bulk metallic glass by ultrasonic welding processing. Mater Lett 130:160–163. https://doi.org/10.1016/j.matlet.2014.05.056

Maeda M, Takahashi Y, Fukuhara M, Wang XM, Inoue A (2007) Ultrasonic bonding of Zr55Cu30Ni5Al10 metallic glass. Mater Sci Eng B 148(1–3):141–144. https://doi.org/10.1016/j.mseb.2007.09.028

Tamura S, Tsunekawa Y, Okumiya M, Hatakeyama M (2007) Ultrasonic cavitation treatment for soldering on Zr-based bulk metallic glass. J Mater Process Tech 206(1–3):322–327. https://doi.org/10.1016/j.jmatprotec.2007.12.032

Li X, Liang X, Zhang ZX, Ma J, Shen J (2020) Cold joining to fabricate large size metallic glasses by the ultrasonic vibrations. Scr Mater 185:100–104. https://doi.org/10.1016/j.scriptamat.2020.03.059

Huang ZY, Fu JN, Li X, Wen WX, Lin HJ, Lou Y, Luo F, Zhang ZX, Liang X, Ma J (2021) Ultrasonic-assisted rapid cold welding of bulk metallic glasses. Sci China Mater. https://doi.org/10.1007/s40843-021-1723-6

Xu WX, Zhang LC (2015) Ultrasonic vibration-assisted machining: principle, design and application. Adv Manuf 3(3):173–192. https://doi.org/10.1007/s40436-015-0115-4

Wang DD (2019) Experimental and simulation study on ultrasonic torsional vibration assisted milling of amorphous alloys. Qinhuangdao: Yanshan University

Wang ZY, Wang DD (2021) Experimental Study on Ultrasonic Vibration-assisted Milling of Metallic Glass. Modular Machine Tool & Automatic Manufacturing Technique (07):170–172+177. https://doi.org/10.13462/j.cnki.mmtamt.2021.07.039

Shan S, Feng PF, Zha HT, Feng F (2020) Building of longitudinal ultrasonic assisted turning system and its cutting simulation study on bulk metallic glass. Materials 13(14):3131. https://doi.org/10.3390/ma13143131

Tsui HP, Lee PH, Yeh CC, Hung JC (2020) Ultrasonic vibration-assisted electrical discharge machining on Fe-based metallic glass by adding conductive powder. Procedia CIRP 95:425–430. https://doi.org/10.1016/j.procir.2020.02.275

Funding

This study was funded by the National Natural Science Foundation of China [grant number U2004169]; Scientific and Technological Project of Henan Province [grant number 202102210275 and 212102210061]; the Young Backbone Teacher Cultivation Plan for Higher Education of Henan University [grant number 2020GGJS129]; and the Scientific and Technological Innovation Team of Colleges and Universities in Henan Province [grant number 20IRTSTHN015].

Author information

Authors and Affiliations

Contributions

Jinguang Du: writing original draft. Biao Tian: writing original draft and editing. Liuyang Duan: check original draft. Wuyi Ming: writing guidance. Kun Liu: check original draft. Wenbin He: guiding framework of paper and check original draft.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent to publish

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Du, J., Tian, B., Duan, L. et al. Traditional and non-traditional machining technology of metallic glass. Int J Adv Manuf Technol 120, 2879–2902 (2022). https://doi.org/10.1007/s00170-022-08923-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-08923-9