Abstract

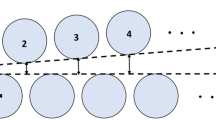

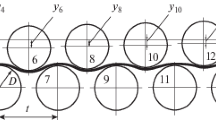

One of the main tasks to determine the technological settings of the sheet leveling machine (leveler) is to identify the maximum roll overlap. In the well-known works on the study of sheet metal-roll leveling, the overlaps are set on the basis of experimental data, which is applicable for the leveling sheets from material with the 800-MPa yield strength. But for materials with a higher yield strength, additional research is required. The purpose of this work is to establish criteria affecting the maximum allowable overlap for the working rolls by the leveler and to determine the dependencies for the most rational working roll adjustment. When solving the set tasks, developed by the authors, an analytical mathematical model of the leveling process was used as an objective function that allows to determine the energy-power characteristics and the sheet curvature after leveling, depending on the individual settings of the leveler rolls. Within the framework of studies, an algorithm of a mathematical model was developed that allows to determine the leveler technological settings necessary for correcting the longitudinal curvature and comes down to determining the aligning coordinates for each of the movable rolls depending on the known characteristics of the metal being processed, the leveler geometric parameters, and the permissible value of the sheet residual curvature after leveling. In consequence of studying the influence of the working roll setup on the sheet metal-roll quality during leveling on a multi-roll leveling machine, the laws for the rational rolls positioning were established. The linear and sinusoidal laws were identified as optimal ones. Boundary factors were also established as affecting the maximum overlap of the rolls. These factors included the condition of the pickup and the condition of the roll strength. Using the example of implementing the developed finite element model of the sheet leveling process at the leveler of NKMZ (Ukraine), it was found that the pickup condition has a dominant influence when leveling sheets with a thickness of less than 6 mm, and with larger thicknesses the condition of the roll strength is prevailing. With a decrease in the yield strength of the material or the width of the sheets, this ratio will be redistributed toward the pickup condition.

Similar content being viewed by others

References

Madej L, Muszka K, Perzyński K et al (2011) Computer aided development of the levelling technology for flat products. CIRP Ann 60(1):291–294. https://doi.org/10.1016/j.cirp.2011.03.137

Lemoine X, Aouafi A (2008) Bauschinger effect correspondence of experimental tests. IntJ Mater Form 1:241–244. https://doi.org/10.1007/s12289-008-0357-9

Hernández UU, Mendiguren J, de Argandoña ES et al (2016) Friction characterisation in levelling processes. Advances in Materials and Processing Technologies 2(4):503–513. https://doi.org/10.1080/2374068X.2016.1247230

Won C, Lee W, Lee H-Y, Kang Y-S, Yoon J (2020) Evaluation of in-plane edge stretchability under severe contact condition for third-generation advanced high-strength steel. Int J Adv Manuf Technol 108:1945–1958. https://doi.org/10.1007/s00170-020-05537-x

Fan QH, Zhang H, Jiang XC, Tian BZ (2017) Study on neutral layer offset of high-strength steel plate straightening of excavator’s working arm. Adv Mech Eng 9(7):1687814017712420. https://doi.org/10.1177/%2F1687814017712420

Lee JB, Kang SS (2018) Numerical modeling of roller leveler for thick plate leveling. Int J Precis Eng Manuf 19(3):425-430. https://doi.org/10.1007/s12541-018-0051-x

Petruška J, Návrat T, Šebek F (2012) A new model for fast analysis of leveling process. Advanced Materials Research 586:389–393. https://doi.org/10.4028/www.scientific.net/AMR.586.389

Mathieu N, Dimitriou R, Parrico A, Potier-Ferry M, Zahrouni H (2011) Flatness defects after bridle rolls: a numerical analysis of levelling. IntJ Mater Form 6(2):255–266. https://doi.org/10.1007/s12289-011-1083-2

Park K, Hwang S (2002) Development of a finite element analysis program for roller leveling and application for removing blanking bow defects of thin steel sheet. ISIJ Int 42(9):990–999. https://doi.org/10.2355/isijinternational.42.990

Barabash AV, Yu E, Gavril’chenko, E. P. Gribkov and O. E. Markov, (2014) Straightening of sheet with correction of waviness. Steel in Translation 44(12):916–920. https://doi.org/10.3103/S096709121412002X

Dratz B, Nalewajk V, Bikard J, Chastel Y (2009) Testing and modelling the behaviour of steel sheets for roll levelling applications. IntJ Mater Form 2:519–522. https://doi.org/10.1007/s12289-009-0560-3

Tsai SY, Chang JYJ (2018) Design of deep learning on intelligent levelling system for industry 4.0 technology. In MATEC Web Conf 185:00026. EDP Sciences. https://doi.org/10.1051/matecconf/201818500026

Cui L, Xian LH, Xiang HL (2011) Analysis of leveling strategy for a plate mill. Advanced Materials Research 145:424–428. https://doi.org/10.4028/www.scientific.net/AMR.145.424

Lee J-S, Huh H, Bae J-G, Lee J-W, Kim D-T (2007) Design optimization of roller straightening process for steel cord using response surface methodology. AIP Conf Proc 908(1):581–586. https://doi.org/10.1063/1.2740873

Grüber M, Hirt G (2017) A strategy for the controlled setting of flatness and residual stress distribution in sheet metals via roller levelling. Procedia engineering 207:1332–1337. https://doi.org/10.1016/j.proeng.2017.10.892

Liu ZF, Luo YX, Yan XC, Wang YQ (2015) Boundary determination of leveling capacity for plate roller leveler based on curvature integration method. J Cent South Univ 22(12):4608-4615. https://doi.org/10.1007/s11771-015-3011-y

Liu Z, Luo Y, Wang Y, Warren Liao T, Deng M (2021) An analytical study of optimal roller intermeshes for the plate leveling process. Proc Inst Mech Eng B J Eng Manuf 235(1-2):278-289. https://doi.org/10.1177/%2F0954405420947959

Meng X, Dengyue S, Shimin X et al (2016) Modeling of intermesh schedule for strong heavy plate roller straightener and finite element method modification. MATEC Web of Conferences 71(02005):1–6. https://doi.org/10.1051/matecconf/20167102005

Cui L, Hu X, Liu X (2011) Research on mathematical model of leveling process for plate mill. Advanced Materials Research 148–149:368–371. https://doi.org/10.4028/www.scientific.net/AMR.148-149.368

Wang Y, Liu Z, Yan X (2012) Evaluation of straightening capacity of plate roll straightener. Journal of Central South University 19(9):2477–2481. https://doi.org/10.1007/s11771-012-1299-4

Shinkin VN (2017) Asymmetric three-roller sheet-bending systems in steel-pipe production. Steel in Translation 47:235–240. https://doi.org/10.3103/S0967091217040106

Silvestre E, Garcia D, Galdos L et al (2016) Roll levelling semi-analytical model for process optimization. J Phys: Conf Ser 734(3):032–034. https://doi.org/10.1088/1742-6596/734/3/032034

Yi G, Wang Z, Hu Z (2020) A novel modeling method in metal strip leveling based on a roll-strip unit. Math Probl Eng 1486864:1–16. https://doi.org/10.1155/2020/1486864

Author information

Authors and Affiliations

Contributions

All authors participated in the design of this work and performed equally. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Disclosure

The submission of the authors’ paper implies that it has not been previously published, that it is not under consideration for publication elsewhere, and that it will not be published elsewhere in the same form without the written permission of the editors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gribkov, E.P., Kovalenko, A.K. & Hurkovskaya, S.S. Research and simulation of the sheet leveling machine manufacturing capabilities. Int J Adv Manuf Technol 120, 743–759 (2022). https://doi.org/10.1007/s00170-022-08806-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-08806-z