Abstract

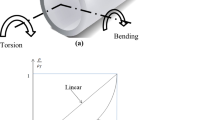

The axial elongation and springback problems of tube bending need to be solved respectively, to realize the “no allowance bending” and “flange welding prior to bending” processes for ship thick-walled tubes. The axial elongation and springback analytical models of the tube bending process are established respectively based on the force balance condition, comprehensively considering the influence law and mechanism of geometric and material intrinsic parameters. The relationships between the axial elongation and forming angle, the bending angle, and forming angle are found respectively. A formula for calculating the start bending point position of the tube is obtained according to the geometric relationship after springback. The finite element (FE) model of the thick-walled tube is established based on the ABAQUS platform; the processes of tube bending and springback are simulated. The accuracy of the established FE model and theoretical analysis models is verified through tube bending experiments. The influence of main process parameters on the axial elongation and springback of the tube bending is analyzed. The results show that for tubes with the same materials, in the scope of engineering application, both the axial elongation and the bending angle have linear relations with the forming angle, and they are not through the origin of the coordinate; the axial elongation of the tube bending increases with the increasing of the forming angle; the springback angle increases with the increasing of the bending angle. At last, the applications of axial elongation and springback law are proposed.

Similar content being viewed by others

Abbreviations

- \(E\) :

-

Elastic modulus

- \(\mu\) :

-

Poisson’s ratio

- \(\sigma_{s}\) :

-

Yield stress

- \(\sigma\) :

-

Real stress

- \(\sigma_{ij}\) :

-

Shear stress

- \(\sigma_{{{\text{ro}}}} ,\sigma_{{{\text{ri}}}}\) :

-

Radial stress of the outer/inner arc portion

- \(\sigma_{\theta \mathrm o} ,\sigma_{\theta \mathrm i}\) :

-

Tangential stress of the outer/inner arc portion

- \(\varepsilon_{{\text{r}}}\) :

-

Radial strain

- \(R\) :

-

Bending radius

- \(\rho\) :

-

Radius of stress and strain NL

- \(R_{{\text{i}}}\) :

-

Radius of inner ridge

- \(t\) :

-

Tube initial wall thickness

- \(t_{{{\text{om}}}}\),\(t_{{{\text{im}}}}\) :

-

Minimum/maximum wall thickness

- \(D\) :

-

Tube outer diameter

- \(y_{{\text{o}}} ,y_{{\text{i}}}\) :

-

Boundary distance of elastic and outer/inner plastic deformation zone

- \(\alpha_{\sigma }\) :

-

Position angle of stress and strain NL

- \(M\) :

-

Total bending moment

- \(M_{{\text{e}}}\) :

-

Bending moment of elastic deformation zone

- \(M_{{{\text{pi}}}}\) :

-

Bending moment of inner plastic deformation zone

- \(\theta\) :

-

Tube bending angle

- \(\Delta \theta\) :

-

Springback angle

- \(l_{{\text{s}}}\) :

-

Start bending length

- \(n\) :

-

Strain hardening exponent

- \(K\) :

-

Strength coefficient

- \(\varepsilon_{s}\) :

-

Yield strain

- \(\varepsilon\) :

-

Real strain

- \(\varepsilon_{ij}\) :

-

Shear strain

- \(\sigma_{\alpha }\) :

-

Circumferential stress

- \(\varepsilon_{\alpha }\) :

-

Circumferential strain

- \(\varepsilon_{\theta }\) :

-

Tangential strain

- \(R^{\prime}\) :

-

Forming radius

- \(R_{{\text{o}}}\) :

-

Radius of outer ridge

- \(e_{{\text{n}}}\) :

-

Stress and strain NL shifting displacement

- \(t^{\prime}\) :

-

Tube forming wall thickness

- \(\Delta t_{{\text{o}}}\),\(\Delta t_{{\text{i}}}\) :

-

Wall thickness changing of outer/inner ridge line

- \(r\) :

-

Tube inner radius

- \(\alpha ,\beta\) :

-

Position angle of boundary of elastic and outer/inner plastic deformation zone

- \(\varphi\) :

-

Position angle in cross section

- \(\overline{t}_{{\text{o}}} ,\overline{t}_{{\text{i}}}\) :

-

Average thickness of inner/outer arc portion

- \(M_{{{\text{po}}}}\) :

-

Bending moment of outer plastic deformation zone

- \(I\) :

-

Cross-sectional moment of inertia

- \(\theta^{\prime}\) :

-

Tube forming angle

- \(\Delta l\) :

-

Axial elongation

- \(\varepsilon_{{\text{p}}}\) :

-

Plastic strain

References

Yang H, Li H, Zhang ZY, Zhan M, Liu J, Li GJ (2012) Advances and trends on tube bending forming technologies. Chin J Aeronaut 25(1):1–12. https://doi.org/10.1016/S1000-9361(11)60356-7

Tang NC (2000) Plastic-deformation analysis in tube bending. Int J Pressure Vessels Pip 77(12):751–759. https://doi.org/10.1016/S0308-0161(00)00061-2

Zhan M, Zhai HD, Yang H (2012) Springback mechanism and compensation of cryogenic Ti alloy tube after numerically controlled bending. Trans Nonferrous Met Soc China 22:S287–S293. https://doi.org/10.1016/S1003-6326(12)61721-X

Zhan M, Wang Y, Yang H, Long H (2016) An analytic model for tube bending springback considering different parameter variations of Ti-alloy tubes. J Mater Process Technol 236:123–137. https://doi.org/10.1016/j.jmatprotec.2016.05.008

Welo T, Paulsen F (2015) Predicting tube ovalization in cold bending: an analytical approach. Key Eng Mater 651:1146–1152. https://doi.org/10.4028/www.scientific.net/KEM.651-653.1146

Zhang ZK, Wu JJ, Guo RC, Wang MZ, Li FF, Guo SC, Wang YA, Liu WP (2016) A semi-analytical method for the springback prediction of thick-walled 3D tubes. Mater Des 99:57–67. https://doi.org/10.1016/j.matdes.2016.03.026

Li H, Yang H, Yan J, Zhan M (2009) Numerical study on deformation behaviors of thin-walled tube NC bending with large diameter and small bending radius. Comput Mater Sci 45(4):921–934. https://doi.org/10.1016/j.commatsci.2008.12.018

Zhan M, Yang H, Huang L, Gu RJ (2006) Springback analysis of numerical control bending of thin-walled tube using numerical-analytic method. J Mater Process Tech 177(1–3):197–201. https://doi.org/10.1016/j.jmatprotec.2006.03.183

Sadowski AJ, Rotter JM (2013) Solid or shell finite elements to model thick cylindrical tubes and shells under global bending. Int J Mech Sci 74:143–153. https://doi.org/10.1016/j.ijmecsci.2013.05.008

Zhu YX, Liu YL, Yang H, Li HP (2013) Improvement of the accuracy and the computational efficiency of the springback prediction model for the rotary-draw bending of rectangular H96 tube. Int J Mech Sci 66:224–232. https://doi.org/10.1016/j.ijmecsci.2012.11.012

Mori S, Manabe KI, Nishimura H, Hirose K (1997) Experimental analysis of the flattening of the cross-section, the springback and the bending moment of clad tubes in uniform bending. J Mater Process Technol 66(1):270–276. https://doi.org/10.1016/S0924-0136(96)02539-3

Liu KX, Liu YL, Yang H (2013) Experimental study on the effect of dies on wall thickness distribution in NC bending of thin-walled rectangular 3A21 aluminum alloy tube. Int J Adv Manuf Technol 68(5–8):1867–1874. https://doi.org/10.1007/s00170-013-4983-0

Goodarzi M, Kuboki T, Murata M (2007) Effect of initial thickness on shear bending process of circular tubes. J Mater Process Technol 191(1):136–140. https://doi.org/10.1016/j.jmatprotec.2007.03.007

Dx E, Liu YF (2010) Springback and time-dependent springback of 1Cr18Ni9Ti stainless steel tubes under bending. Mater Des 31(3):1256–1261. https://doi.org/10.1016/j.matdes.2009.09.026

Dx E, Guan ZP, Chen JS (2012) Influence of additional tensile force on springback of tube under rotary draw bending. J Mater Eng Perform 21(11):2316–2322. https://doi.org/10.1007/s11665-012-0202-7

Dx E, Li RT (2015) Influence of additional tensile force on the stress and deformation of numerically controlled tube bending. Int J Adv Manuf Technol 78(5–8):895–905. https://doi.org/10.1007/s00170-014-6675-9

Engel B, Hassan HR (2014) Investigation of neutral axis shifting in rotary draw bending processes for tubes. Steel Res Int 85(7):1209–1214. https://doi.org/10.1002/srin.201300333

Song FF, Yang H, Li H, Zhan M, Li GJ (2013) Springback prediction of thick-walled high-strength titanium tube bending. Chin J Aeronaut 26(05):1336–1345. https://doi.org/10.1016/j.cja.2013.07.039

Jiang ZQ, Yang H, Zhan M, Yue YB, Liu J, Xu XD, Li GJ (2009) Establishment of a 3D FE model for the bending of a titanium alloy tube. Int J Mech Sci 52(9):1115–1124. https://doi.org/10.1016/j.ijmecsci.2009.09.029

Jiang ZQ, Yang H, Zhan M, Xu XD, Li GJ (2010) Coupling effects of material properties and the bending angle on the springback angle of a titanium alloy tube during numerically controlled bending. Mater Des 31(4):2001–2010. https://doi.org/10.1016/j.matdes.2009.10.029

Murata M, Kuboki T, Takahashi K, Goodarzi M, Jin Y (2007) Effect of hardening exponent on tube bending. J Mater Process Technol 201(1):189–192. https://doi.org/10.1016/j.jmatprotec.2007.11.286

Zhou YP, Li PF, Li MZ, Wang LY, Sun S (2018) Residual stress and springback analysis for 304 stainless steel tubes in flexible-bending process. Int J Adv Manuf Technol 94(1–4):1317–1325. https://doi.org/10.1007/s00170-017-0993-7

Wei WB, Wang H, Xiong H, Cheng X, Tao J, Guo XZ (2020) Research on influencing factors and laws of free-bending forming limit of tube. Int J Adv Manuf Technol 106(3–4):1421–1430. https://doi.org/10.1007/s00170-019-04692-0

Li H, Yang H, Xu J, Liu H, Wang D, Li GJ (2013) Knowledge-based substep deterministic optimization of large diameter thin-walled Al-alloy tube bending. Int J Adv Manuf Technol 68(9–12):1989–2004. https://doi.org/10.1007/s00170-013-4811-6

Li H, Ma J, Liu BY, Gu RJ, Li GJ (2018) An insight into neutral layer shifting in tube bending. Int J Mach Tools Manuf 126:51–70. https://doi.org/10.1016/j.ijmachtools.2017.11.013

Funding

This work was supported by the National Natural Science Foundation of China (No. 51779200).

Author information

Authors and Affiliations

Contributions

Huan Zhang: study conception and design, theoretical derivation, acquisition of data, analysis and interpretation of data, drafting of manuscript. Yong Hu: critical revision, study conception and design, funding acquisition.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, H., Hu, Y. Research on the axial elongation and springback law of thick-walled tubes in cold bending forming. Int J Adv Manuf Technol 120, 669–689 (2022). https://doi.org/10.1007/s00170-022-08794-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-08794-0