Abstract

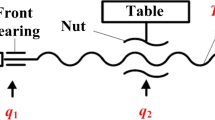

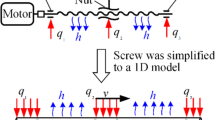

In order to investigate the effect of thermal expansion on the ball screw feed system (BSFS) of a precision machine tool, theoretical modeling of and experimental study on thermally induced error are focused in this paper. A series of thermal experiments are conducted on the machine tool to measure the temperature of the main heat source and measuring points of BSFS. This study is to classify the main heat sources and discuss the impact on the ball screw feed system separately. By the experimental data of ball screw system, the thermal model of screw shaft in the axial direction is analyzed and verified. Based on the heat generation and transfer analysis of ball screw system, thermal expansion of screw shaft in the axial direction is modeled mathematically. In addition, by analyzing the effects of machining parameters such as rotational speed, preloads, and lead, we get the parameter influence of BSFS’s temperature rising and thermal deformation. This work can help us reduce thermal deformation effectively and improve the precision of CNC machining.

Similar content being viewed by others

Availability of data and material

The data sets supporting the results of this article are included within the article and its additional files.

References

Hu S, Ma C, Y J, Zhao L, Mei X, Gong G (2015) Investigation into effect of thermal expansion on thermally induced error of ball screw feed drive system of precision machine tools. Int J Mach Tools Manuf 9760–17

Mayr J, Jedrzejewski J, Uhlmann E (2012) Thermal issues in machine tools. CIRP Ann Manuf Technol 61(2):771–791

Venugopal R, Barash M (1986) Thermal effects on the accuracy of numerically controlled machine tools. CRIP Ann Manuf Techn 35(1):255–258

Week M, Zangs L (1975) Computing the thermal behavior of machine tools using the finite element method-possibilities and limitations. Proc 16th MTDR Confe 16:185–194

Xu ZZ, Liu XJ, Kim HK, Shin JH, Lyu SK (2011) Thermal error forecast and performance evaluation for an air-cooling ball screw system. Int J Adv Manuf Tech 51(7–8):605–611

Ming X, Jiang S (2011) A thermal model of a ball screw feed drive system for a machine tool. Proc Inst Mech Eng Part C J Mech Eng Sci 225(1):186–193

Li Z, Fan K, Yang J, Zhang Y (2014) Time-varying positioning error modeling and compensation for ball screw systems based on simulation and experimental analysis. Int J Adv Manuf Tech 73:5–8

Oyanguren A, Larrañaga J, Ulacia I (2018) Thermo-mechanical modelling of ball screw preload force variation in different working conditions. Int J Adv Manuf Technol 2:1–17

Huang S, Feng P, Xu C, Ma Y, Ye J, Zhou K (2018) Utilization of heat quantity to model thermal errors of machine tool spindle. Int J Adv Manuf Tech 97(5_8):1733–1743

Li T, Zhao C, Zhang Y (2017) Adaptive real-time model on thermal error of ball screw feed drive systems of CNC machine tools. Springer, London 94(9–12):3853–3861

Yun WS, Kim SK, Cho DW (1999) Thermal error analysis for a CNC lathe feed drive system. Int J Mach Tools Manuf 39:1087–1101

Ramesh R, Mannan MA, Po AN (2003) Thermal error measure-ment and modeling in machine tools. Part I Influence of varying operation condition, Int J Mach Tools Manuf 43:391–440

Xu ZZ, Liu XJ (2011) Thermal error forecast and performance evaluation for an air-cooling ball screw system. Int J Mach Tools Manuf 51:605–611

Xu ZZ, Liu XJ (2014) Study on thermal behavior analysis of nut/ shaft air cooling ball screw for high-precision feed drive. Int J Precis Eng Manuf 15:123–128

Zhang Y, Yang JG, Jiang H (2012) Machine tool thermal error modeling and prediction by grey Neural network. Int J Adv Manuf Technol 59(9–12):1065–1072

Lee J, Lee JH, Yang SH (2001) Thermal error modeling of a horizontal machining center using fuzzy logic strategy. J Manuf Process 3(2):120–127

Ma C, Yang J, Mei XS, Zhao L, Dong HS, Zhang S (2017) Dynamic thermal-structure coupling analysis and experimental study on ball screw feed drive system of precision machine tools. Appl Mech Mater 868:124–135

Han J, Wang LP, Wang HT (2012) A new thermal error modeling method for NC machine tools. Int J Adv Manuf Technol 62:205–212

Wu CW, Tang CH, Chang CF, Shiao YS (2012) Thermal error compensation method for machine center. Int J Adv Manuf Technol 59:681–689

Wang W, Zhang Y, Yang JG, Zhang YS, Yuan F (2012) Geometric and thermal error compensation for CNC milling machines based on Newton interpolation method. Proc IME C J Mech Eng Sci 227:771–778

Wu H, Zhang HT, Guo QJ, Wang XH, Yang JG (2008) Thermal error optimization modeling and real-time compensation on a CNC turning center. J Mater Process Tech 207:172–179

Xu ZZ, Choi C, Liang LJ (2015) Study on a novel thermal error compensation system for high-precision ball screw feed drive (1st report: model, calculation and simu- lation). Int J Precis Eng Man 16:2005–2011

Xu ZZ, Choi C, Liang LJ (2015) Study on a novel thermal error compensation system for high-precision ball screw feed drive (2nd report: experimental verification). Int J Precis Eng Man 16:2139–2145

Zhang J, Li B, Zhou C, Zhao W (2016) Positioning error prediction and compensation of ball screw feed drive system with different mounting conditions. Proc Inst Mech Eng Part B J Eng Manuf 230(12)

Wei X, Gao F, Li Y, Zhang D (2018) Study on optimal independent variables for the thermal error model of CNC machine tools. Int J Adv Manuf Tech 98:(1–4)

Sun YP, Wang DL, Dong HM (2016) A seven-sensor con- figuration method for testing thermal error of a horizontal machining center with linear optical grating scale. Proc IMechE, Part C: J Mech Eng Sci 231:2681–2689

Li Y, Zhang J, Su D, Zhou C, Zhao W (2018) Experiment-based thermal behavior research about the feed drive system with linear scale. Adv Mech Eng 10(11):168781401881235

Harris TA (1991) Rolling Bearing Analysis. Wiley & Sons, New York

Tian R, He R (2004) Solution for heating of ball screw and environmental engineering, World Manuf. Eng Mark 3:65–67

Verl A, Frey S (2010) Correlation between feed velocity and preloading in ball screw drives. Ann CIRP 59(2):429–432

Xu ZZ, Liu XJ, Kim HK, Shin JH, Lyu SK (2011) Thermal error forecast and performance evaluation for an air-cooling ball screw system. Int J Mach Tools Manuf 51:605–611

Xia J, Hu Y, Wu B, Shi T (2009) Research on thermal dynamics characteristics and modeling approach of ball screw. Int J Adv Manuf Tech 43:(5–6)

Hu S, Ma C, Y J, Zhao L, Mei X, Gong G, (2015) Investigation into effect of thermal expansion on thermally induced error of ball screw feed drive system of precision machine tools. Int J Mach Tools Manuf 97:60–17

Liu B (2013) Research on temperature field and thermal deformation of feed system of gantry machining center. Nanjing Univ Aeronaut Astronaut

Bapat VA, Srinivasan P (1971) Method of separation of variables for the solution of certain nonlinear partial differential equations. J Eng Mech 93(2):162

Zhang D, Jia H (2007) Numerical analysis of leaky modes in two-dimensional photonic crystal waveguides using Fourier series expansion method with perfectly matched layer E90C(3):613–622

Yuan J, Yang J, Jun N (1999) Thermal error mode analysis and robust modeling for error compensation on a CNC turning center. Int J Mach Tools Manuf 39(9):1367–1381

Zhang LC, Zu L (2019) A new method to calculate the friction coefficient of ball screws based on the thermal equilibrium. Adv Mech Eng 11(1):168781401882073

Li R, Lin W, Zhang J, Chen Z, Li C, Shuang Q (2018) Research on thermal deformation of feed system for high-speed vertical machining center. Procedia Comput Sci 131:469–476

Funding

The work was supported by National Natural Science Foundation of China (Grant No. 52075087), the Fundamental Research Funds for the Central Universities (Grant No. N2003006 and N2103003), and National Natural Science Foundation of China (Grant No. U1708254).

Author information

Authors and Affiliations

Contributions

Jiancheng Yang: methodology; investigation; experimental; writing-original draft; writing-review and editing. Changyou Li: resources and supervision. Mengtao Xu: resources, writing-reviewing and editing, supervision, writing-review and editing. Yimin Zhang: resources and supervision.

Corresponding author

Ethics declarations

Ethics approval

This chapter does not contain any studies with human participants or animals performed by any of the authors.

Consent to participate

Not applicable. The article involves no studies on humans.

Consent for publication

All authors have read and agreed to the published version of the manuscript.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, J., Li, C., Xu, M. et al. Analysis of thermal error model of ball screw feed system based on experimental data. Int J Adv Manuf Technol 119, 7415–7427 (2022). https://doi.org/10.1007/s00170-022-08752-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-08752-w