Abstract

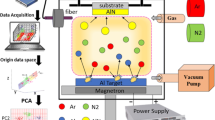

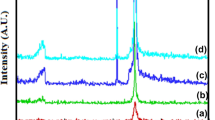

The amount of residual stress generated during the growth process of aluminum nitride (AlN) thin films prepared by pulsed DC reactive magnetron sputtering was investigated. The evaluated process parameters were pulsed DC frequency, DC power and flow gas ratio. AlN film may crack or peel from the substrate due to significant film residual stress. Therefore, the control of residual stress in films is very important for the synthesis of mechanically stable AlN films. A correlation between the residual stress and the crystal orientation of the films was studied. X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FTIR), transmission electron microscope (TEM) and scanning electron microscopy (SEM) were used to measure the residual stress, crystal structure and thickness in AlN films. The results show that AlN film has a different structure and stress characteristic under different deposition conditions. The film residual stress correlates well with the film thickness. Besides, in situ optical emission spectroscopy (OES) big data were analyzed using principal component analysis (PCA) in this study. The PC1-DEV (standard deviation in the first principal component direction) was used to calculate the value residual stress (VRS) to accurately predict and classify the stress state of the deposited film, i.e., compression stress or tensile stress. The Box–Behnken experimental design was applied, a mathematical design of experiment (DOE) model was established based on the response surface method (RSM), and the optimum conditions for generating the minimum residual stress were determined.

Similar content being viewed by others

Data availability

The authors confirm that the data supporting the findings of this study are available within the article.

References

Padmalochan P, Ramaseshana R, Ravib N, Mangammaa G, Feby J, Dasha S, Suzukic K, Suematsuc H (2017) Reduction of residual stress in AlN thin films synthesized by magnetron sputtering technique. Mater Chem Phys 200:78–84. https://doi.org/10.1016/j.matchemphys.2017.07.072

Markoc H (2008) Handbook of nitride semiconductors and devices. Wiley-Vch Verlag GmbH & Co KGaA 155(156):10

Pan TS, Zhang Y, Huang J, Zeng B, Hong DH, Wang SL, Zeng HZ, Gao M, Huang W, Lin Y (2012) Enhanced thermal conductivity of polycrystalline aluminum nitride thin films by optimizing the interface structure. J Appl Phys 112(4):044905. https://doi.org/10.1063/1.4748048

Hirayama H, Fujikawa S, Noguchi N, Norimatsu J, Takano T, Tsubaki K, Kamata N (2009) 222–282 nm AlGaN and InAlGaN-based deep-UV LEDs fabricated on high-quality AlN on sapphire. Phys Status Solidi (a) 206(6):1176–1182. https://doi.org/10.1002/pssa.200880961

Okada G, Kato T, Nakauchi D, Fukuda K, Yanagida T (2016) Photochromism and thermally and optically stimulated luminescences of AlN ceramic plate for UV sensing. Sens Mater 28:897–904. https://doi.org/10.18494/SAM.2016.1250

Berg NG, Paskova T, Ivanisevic A (2017) Tuning the biocompatibility of aluminum nitride. Mater Lett 189:1–4. https://doi.org/10.1016/j.matlet.2016.11.041

Taurino A, Signore MA, Catalano M, Kim MJ (2017) (1 0 1) and (0 0 2) oriented AlN thin films deposited by sputtering. Mater Lett 200:18–20. https://doi.org/10.1016/j.matlet.2017.04.081

Cheng H, Sun Y, Zhang JX, Zhang YB, Yuan S, Hing P (2003) AlN films deposited under various nitrogen concentrations by RF reactive sputtering. J Cryst Growth 254(1–2):46–54. https://doi.org/10.1016/S0022-0248(03)01176-X

Venkataraj S, Severin D, Drese R, Koerfer F, Wuttig M (2006) Structural, optical and mechanical properties of aluminium nitride films prepared by reactive DC magnetron sputtering. Thin Solid Films 502(1–2):235–239. https://doi.org/10.1016/j.tsf.2005.07.281

Mahmood A, Rakov N, Xiao M (2003) Influence of deposition conditions on optical properties of aluminum nitride (AlN) thin films prepared by DC-reactive magnetron sputtering. Mater Lett 57(13–14):1925–1933. https://doi.org/10.1016/S0167-577X(02)01106-0

Zetterling CM, Östling M, Wongchotigul K, Spencer MG, Tang X, Harris CI, Nordell N, Wong SS (1997) Investigation of aluminum nitride grown by metal–organic chemical-vapor deposition on silicon carbide. J Appl Phys 82(6):2990–2995. https://doi.org/10.1063/1.366136

Kelly PJ, Arnell RD (2000) Magnetron sputtering: a review of recent developments and applications. Vacuum 56(3):159–172. https://doi.org/10.1016/S0042-207X(99)00189-X

Sellers J (1998) Asymmetric bipolar pulsed DC: the enabling technology for reactive PVD. Surf Coat Technol 98(1–3):1245–1250. https://doi.org/10.1016/j.tsf.2005.07.281

Choudhary RK, Mishra P, Biswas A, Bidaye AC (2013) Structural and optical properties of aluminum nitride thin films deposited by pulsed DC magnetron sputtering. ISRN Mater Sci 2013:1–5. https://doi.org/10.1155/2013/759462

James M, Jimmy I (1995) Big data analytics for smart manufacturing: Case studies in semiconductor manufacturing. Processes 5(3):39. https://doi.org/10.3390/pr5030039

Butler SW, Edgar TF (1996) Case studies in equipment modeling and control in the microelectronics industry, introduction to the chemical process control —V, Processes Fifth International Conference on Chemical Process Control, Tahoe, CA, p 133–144

Limanond S, Si J, Tsakalis K (1998) Monitoring and control of semiconductor manufacturing processes. IEEE Control Syst 18(6):46–58. https://doi.org/10.1109/37.736011

Yue HH, Qin SJ, Markle RJ, Nauert C, Gatto M (2000) Fault detection of plasma etchers using optical emission spectra. IEEE Trans Semicond Manuf 13(3):374–385. https://doi.org/10.1109/66.857948

Wang SH, Chang HE, Lee CC, Fuh YK, Li TT (2020) Evolution of a-Si: H to nc-Si: H transition of hydrogenated silicon films deposited by trichlorosilane using principle component analysis of optical emission spectroscopy. Mater Chem Phys 240:122186. https://doi.org/10.1016/j.matchemphys.2019.122186

Huang HJ, Kau LH, Wang HS, Hsieh YL, Lee CC, Fuh YK, Li TT (2018) Large-scale data analysis of PECVD amorphous silicon interface passivation layer via the optical emission spectra for parameterized PCA. Int J Adv Manuf Technol 101(1–4):329–337. https://doi.org/10.1007/S00170-018-2938-1

Acosta J, Rojo A, Salas O, Oseguera J (2007) Process monitoring during AlN deposition by reactive magnetron sputtering. Surf Coat Tech 201:7992–7999. https://doi.org/10.1016/j.surfcoat.2007.03.048

Escobar D, Ospina R, Gómez AG, Restrepo-Parra E (2015) Microstructure, residual stress and hardness study of nanocrystalline titanium–zirconium nitride thin films. Ceram Int 41(1):947–952. https://doi.org/10.1016/j.ceramint.2014.09.012

Machunze R, Janssen GCAM (2008) Stress gradients in titanium nitride thin films. Surf Coat Technol 203(5–7):550–553. https://doi.org/10.1016/j.surfcoat.2008.05.005

Ferreira NG, Abramof E, Leite NF, Corat EJ, Trava-Airoldi VJ (2002) Analysis of residual stress in diamond films by x-ray diffraction and micro-raman spectroscopy. J Appl Phys 91(4):2466–2472. https://doi.org/10.1063/1.1431431

Xi Y, Gao K, Pang X, Yang H, Xiong X, Li H, Volinsky AA (2017) Film thickness effect on texture and residual stress sign transition in sputtered TiN thin films. Ceram Int 43(15):11992–11997. https://doi.org/10.1016/j.ceramint.2017.06.050

Ding Z, Sun G, Guo M, Jiang X, Li B, Liang SY (2020) Effect of phase transition on micro-grinding-induced residual stress. J Mater Process Technol 281:116647. https://doi.org/10.1016/j.jmatprotec.2020.116647

Sanz-Hervás A, Iborra E, Clement M, Sangrador J, Aguilar M (2003) Influence of crystal properties on the absorption IR spectra of polycrystalline AlN thin films. Diam Relat Mater 12(3–7):1186–1189. https://doi.org/10.1016/S0925-9635(02)00228-5

Pandey A, Dutta S, Gupta N, Kaur D, Raman R (2021) Evaluation of residual stress of c oriented AlN/Si (111) and its impact on mushroom-shaped piezoelectric resonator. J Mater Sci Mater Electron 32:13499–13510. https://doi.org/10.21203/rs.3.rs-211735/v1

Freddi A, Veschi D, Bandini M, Giovani G (1997) Design of experiments to investigate residual stresses and fatigue life Improvement by a surface treatment. Fatigue Fract Eng Mater Struct 20(8):1147–1157. https://doi.org/10.1111/j.1460-2695.1997.tb00319.x

Maleki E, Unal O, Kashyzadeh KR (2019) Efficiency analysis of shot peening parameters on variations of hardness, grain size and residual stress via Taguchi approach. Met Mater Int 25(6):1436–1447. https://doi.org/10.1007/s12540-019-00290-7

Jeen HS, May GS, Dong-Cheol P (2003) Neural network modeling of reactive ion etching using optical emission spectroscopy data. IEEE Trans Semicond Manuf 16(4):598–608. https://doi.org/10.1109/TSM.2003.818976

Jia X, Jin C, Buzza M, Wang W, Lee J (2016) Wind turbine performance degradation assessment based on a novel similarity metric for machine performance curves. Renew Energ 99:1191–1201. https://doi.org/10.1016/j.renene.2016.08.018

Kar JP, Bose G, Tuli S (2006) Correlation of electrical and morphological properties of sputtered aluminum nitride films with deposition temperature. Curr Appl Phys 6(5):873–876. https://doi.org/10.1016/j.cap.2005.05.001

Aziz ARA, Aziz SA (2018) Application of Box Behnken design to optimize the parameters for Kenaf-epoxy as noise absorber. IOP Conference Series: Mater Sci Eng 454:012001. https://doi.org/10.1088/1757-899X/454/1/012001

Martínez JC, Chequer NA, González JL, Cordova T (2013) Alternative methodology for Gold nanoparticles diameter characterization using PCA technique and UV-VIS spectrophotometry. Nanosci Nanotechnol 2(6):184–189. https://doi.org/10.5923/j.nn.20120206.06

Kelly PJ, Henderson PS, Arnell RD, Roche GA, Carter D (2000) Reactive pulsed magnetron sputtering process for alumina films. J Vac Sci Technol A 18(6):2890–2896. https://doi.org/10.1116/1.1319679

Chiu KH, Chen JH, Chen HR, Huang RS (2007) Deposition and characterization of reactive magnetron sputtered aluminum nitride thin films for film bulk acoustic wave resonator. Thin Solid Films 515(11):4819–4825. https://doi.org/10.1016/j.tsf.2006.12.181

Mirpuri C, Xu S, Long JD, Ostrikov K (2007) Low-temperature plasma-assisted growth of optically transparent, highly oriented nanocrystalline AlN. J Appl Phys 101(2):024312. https://doi.org/10.1063/1.2423224

Edgar JH, Carosella CA, Eddy JCR, Smith DT (1996) Effect of beam voltage on the properties of aluminium nitride prepared by ion beam assisted deposition. J Mater Sci Mater Electron 7:247–253. https://doi.org/10.1007/BF00188950

Jiao X, Shi Y, Zhong H, Zhang R, Yang J (2014) AlN thin films deposited on different Si-based substrates through RF magnetron sputtering. J Mater Sci Mater Electron 26(2):801–808. https://doi.org/10.1007/s10854-014-2467-0

Suzuki K, Kijima K (2006) Preparation and dielectric properties of polycrystalline films with dense nano-structured BaTiO3 by chemical vapor deposition using inductively coupled plasma. Vacuum 80(6):519–529. https://doi.org/10.1016/j.vacuum.2005.08.025

Molleja JG, G´omez BJ, Ferr´on J, Gautron E, B¨urgi J, Abdallah B, Djouadi MA, Feugeas J, Jouan PY, (2013) AlN thin films deposited by DC reactive magnetron sputtering: effect of oxygen on film growth. EPJ Appl Phys 64:20302. https://doi.org/10.1051/epjap/2013130445

Lu TY, Yang YP, Lo HH, Wang PJ, Lai W, Fuh YK, Li TT (2021) Minimizing film residual stress with in-situ OES big data using principle component analysis of deposited AlN films by pulsed DC reactive sputtering. J Adv Manuf Technol 114:1975–1990. https://doi.org/10.1007/s00170-021-07003-8

Ewulonu CM, Chukwuneke JL, Nwuzor IC, Achebe CH (2020) Fabrication of cellulose nanofiber/polypyrrole/polyvinylpyrrolidone aerogels with box-Behnken design for optimal electrical conductivity. Carbohydr Polym 235:116028. https://doi.org/10.1016/j.carbpol.2020.116028

Gallego Ríos SE, Peñuela GA, Ramírez Botero CM (2017) Method validation for the determination of mercury, cadmium, lead, arsenic, copper, iron, and zinc in fish through microwave-induced plasma optical emission spectrometry (MIP OES). Food Anal Methods 10:3407–3414. https://doi.org/10.1007/s12161-017-0908-0

Aveyard J, Bradley JW, McKay K, McBride F, Donaghy D, Raval R, D’Sa RA (2017) Linker-free covalent immobilization of nisin using atmospheric pressure plasma induced grafting. J Mater Chem B 5:2500–2510. https://doi.org/10.1039/C7TB00113D

Acknowledgements

This study was financially supported by Delta Electronics, Inc. Taiwan and Department of Mechanical Engineering, National Central University, Taiwan.

Funding

This work was financially funded by Delta Electronics, Inc. under contract No.108K92.

Author information

Authors and Affiliations

Contributions

All authors contributed equally to the generation and analysis of experimental data, and the development of the manuscript.

Corresponding author

Ethics declarations

Ethical approval

Since the study is performed on the silicon samples, there is no need for ethical approval; however, all the tests are done in National Central University, in the Optical Sciences Center, and in SEM and XRD Labs of Precious Instrument Utilization Center under the control of trained experts. Additionally, the paper main data are not published elsewhere.

Consent to participate

All authors declare that have agreed for authorship, have read and approved the manuscript, and have given the consent for submission and subsequent publication of the manuscript.

Consent to publish

All authors are consenting to publish this article with its included data in The International Journal of Advanced Manufacturing Technology and approve its final version.

Competing interests

The authors declare that they have no competing of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lo, HH., Chen, WL., Wang, P.J. et al. Residual stress classification of pulsed DC reactive sputtered aluminum nitride film via large-scale data analysis of optical emission spectroscopy. Int J Adv Manuf Technol 119, 7449–7462 (2022). https://doi.org/10.1007/s00170-022-08714-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-08714-2