Abstract

This paper presents an overview of the recent advances in optimization of die design through finite element analysis for aluminum alloys of 6xxx series. The die design and optimization play a crucial role in the production of 6xxx series alloys, in order to attain high quality’s final products. Before the use of finite element analysis (FEA) in aluminum extrusion industry, many experiments and modifications are needed until an acceptable product becomes available. The use of finite element analysis acquires a key role in the direction of eliminating trials and defective extrudates and use is gaining more and more ground through most of the manufacturers. This review will show how various studies try to enhance the performance of the extrusion dies through simulations and how the majority of the most common defects could be prevented if the use of the suitable software and techniques are implemented. The main covered areas from the current review are material flow optimization, flow balance in extrusion of complex aluminum profiles, spread extrusion die design, optimization of porthole extrusion dies, front end and back end defects, die bearing geometry and surface defects, automatic die design optimization and liquid nitrogen die cooling.

Similar content being viewed by others

References

HyperXtrude (Version 14.0) (2016) Simulation software for extrusion analysis. Altair engineering inc. USA

Walters J, Foster M, Bandar A (2012) The ‘State of the Art’ in aluminum extrusion simulation using the finite element method. Extrusion Technology

Hora P, Becker C, Tong L (2016) A Special-purpose FE simulation method for virtual modeling of complex hollow profile extrusion processes. Extrusion Technology

Engelhardta M, Kurmajev S, Maier J, Becker C, Hora P (2019) The application of FEA for optimization of die design. Materials Today: Proceedings 10:226–233

Donati L, Tomesani L, Schikorra M, Khalifa NB, Tekkaya AE (2010) Friction model selection in FEM simulations of aluminum extrusion. Int J Surf Sci Eng 4(1):27–41

Khalifa NB, Tekkaya AE (2011) Newest developments in the manufacture of helical profiles by hot extrusion. ASME Conf Proc 459

Reggiani B, Segatori A, Donati L, Tomesani L (2012) Finite element modeling of the charge weld evolution in a porthole die. Key Eng Mater 491:19–26

Mahmoodkhani Y, Chen J, Wells MA, Poole WJ, Parson NC (2019) The effect of die bearing geometry on surface recrystallization during extrusion of an Al-Mg-Si-Mn alloy. Metallurgical and Materials Transactions A 50

Mayavaram R, Sajja U, Secli C, Niranjan S (2013) Optimization of bearing lengths in aluminum extrusion dies. Procedia CIRP 12:276–281

Dong Y, Zhang C, Luo W, Yang S, Zhao G (2016) Material flow analysis and extrusion die modifications for an irregular and multitooth aluminum alloy radiator. Int J Adv Manuf Technol 85:1927–1935

Qamar SZ, Pervez T, Chekotu JC (2018) Die defects and die corrections in metal extrusion. Metals 8:380

Foster M, Joseph D (2016) Using FEM to model and troubleshoot extrusion die failures. Extrusion Technology

Hora P, Becker C, Tong L, Maier J, Müller S (2013) Advanced frictional models for extrusion application. Key Eng Mater

Kloppenborg T, Schwane M, Ben Khalifa N, Tekkaya AE, Brosius A (2012) Experimental and numerical analysis of material flow in porthole die extrusion. Key Eng Mater 491:97–104

Sun D, Kailer A, Andrieux F, Ockewitz A (2012) Determination of friction behavior in extrusion processes with a new experimental method. Extrusion Technology

Reggiani B, Donati L, Tomesani L (2017) Multi-Goal Virtual Optimization of Industrial Extrusion Dies. Int J Adv Manuf Technol 88:3281–3293

Zhang C, Yang S, Zhao G, Gao A, Wang L (2016) Investigation of material flow and thermal behavior during the transient stage of extrusion. Extrusion Technology

Fang G, Zhou J, Duszczyk J (2009) FEM simulation of aluminium extrusion through two-hole multi-step pocket dies. J Mater Process Technol 209:1891–1900

Zhao G, Chen H, Zhang C, Guan Y, Anjiang G, Peng L (2014) Die optimization design and experimental study of a large wallboard aluminum alloy profile used for high-speed train. Int J Adv Manuf Technol

Bastani FA, Aukrust T, Brandal S (2012) Study of effects of variations in process parameters on the extrusion process by use of finite element simulations. Extrusion Technology

Ammu V, Mahendiran P, Agnihotri A, Ambade S, Dungore PR (2018) A simplified approach for generation of bearing curve by velocity distribution and press validation for aluminum extruded profile. The International Journal of Advanced Manufacturing Technology 98:1733–1744

Sheppard T (1999) Extrusion of aluminium alloys. Kluwer Academic Publishers, Dordrecht

Park N, Song Y, Bae G, Jung S, Song J, Lee J, Choi S, Lee H, Sung H (2020) Evaluation of the effect of ram speed for extrusion of Al6063 based on ALE-based finite element analysis of L-shaped sample. Procedia Manufacturing 50:673–676

Lin Z, Juchen X, Xinyun W, Guoan H (2003) Optimization of die profile for improving die life in the hot extrusion process. J Mater Process Technol 142:659–664

Mueller S, Sanabria V (2018) Influence of choked angle of bearing channel on profile grain structure during multi-hole extrusion of aluminum alloy. Procedia Manufacturing 15:201–208

Valberg H, Nolte D, Khan YA (2014) On The Balance of The Metal Flow In Porthole Dies With Differently Sized Porthole Channels. Key Eng Mater 585:77–84

Biba N, Stebunov S, Lishny A (2014) Simulation of material flow coupled with die analysis in complex shape extrusion. Key Eng Mater 585:85–92

Khan YA, Valberg HS (2011) Studies of porthole extrusion through die with different sizes of portholes. AIP Conference Proceedings

Solomon N, Solomon I (2010) Effect of die shape on the metal flow pattern during direct extrusion process. Rev Metal 46:396–404

Zhang C, Zhao G, Guan Y, Gao A, Wang L, Li P (2015) Virtual tryout and optimization of the extrusion die for an aluminum profile with complex cross-sections. Int J Adv Manuf Technol 78:927–937

Xiang S, Zhou C, Cai Y (2012) Application of numerical simulation technology to optimize die designs for the production of complex aluminum profiles. Extrusion Technology

Qamar SZ, Chekotu JC, Qamar SB (2019) Effect of shape complexity on ram pressure and metal flow in aluminum extrusion. JOM 71(12)

Jie YI, Wang ZH, Liu ZW, Zhang JM, Xin HE (2018) analysis of extrusion defect and optimization of metal flow in porthole die for complex hollow aluminum profile. Trans Nonferrous Met Soc China 28:2094−2101

Peng Z, Sheppard T (2005) Effect of die pockets on multi-hole die extrusion. Mater Sci Eng A 407:89–97

Fang G, Zhou J, Duszczyk J (2008) Effect of pocket design on metal flow through single-bearing extrusion dies to produce a thin-walled aluminium profile 199:91–101

Truong T, Hsu Q, Tong V, Sheu J (2020) A design approach of porthole die for flow balance in extrusion of complex solid aluminum heatsink profile with large variable wall thickness. Metals 10:553

Sun X, Zhao G, Zhang C, Guan Y, Gao A (2013) Optimal design of second-step welding chamber for a condenser tube extrusion die based on the response surface method and the genetic algorithm. Mater Manuf Processes 28:823–834

Truong T, Hsu Q, Tong V (2020) Effects of Solid Die Types in Complex and Large-Scale Aluminum Profile Extrusion. Appl Sci 10:263

Kloppenborg T, Brosius A, Erman Tekkaya A (2010) Numerical Material Flow Optimization of a Multi-Hole Extrusion Process. Adv Mater Res 83–86:826–833

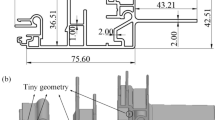

Liu Z, Li L, Yi J, Wang G (2019) Entrance shape design of spread extrusion die for large-scale aluminum panel. Int J Adv Manuf Technol 101:1725–1740

Liu Z, Li L, Wang G, Yi J (2020) Analysis and improvement of material flow during extrusion process using spreading pocket die for large-size, flat-wide, and multi-ribs profile. Int J Adv Manuf Technol 107:1115–1129

Wang D, Zhang C, Wang C, Zhao G, Chen L, Sun W (2018) Application and analysis of spread die and flat container in the extrusion of a large-size, hollow, and flat-wide aluminum alloy profile. Int J Adv Manuf Technol 94:4247–4263

Imamura Y, Takatsuji N, Matsuki K, Tokizawa M, Murotani K, Maruyama H (1999) Metal flow behaviour of wide flat bar in the spreading extrusion process. Mater Sci Technol 15

Ayer Ö, Bingö S, Karakaya İ (2019) An extrusion simulation of an aluminum profile by porthole die. Vibroengineering procedia 27

Fang W, Tang D, Wang H, Li D, Peng Y (2020) Optimization of die design for thin-walled flat multi-port tube with the aid of finite element simulation. J Mater Process Technol 277

Gagliardi F, Ambrogio G, Filice L (2012) On the die design in AA6082 porthole extrusion. CIRP Ann Manuf Technol 61:231–234

Zhang C, Chen H, Zhao G, Zhang L, Lou S (2016) Optimization of porthole extrusion dies with the developed algorithm based on finite volume method. Int J Adv Manuf Technol 85:1901–1913

Xianghong W, Zhao G, Yiguo L, Xinwu M (2006) Numerical simulation and die structure optimization of an aluminum rectangular hollow pipe extrusion process. Mater Sci Eng A 435–436:266–274

Gonçalves ND, Carneiro OS, Nóbrega JM (2013) Design of com- plex profile extrusion dies through numerical modeling. J Nonnewton Fluid Mech 200:103–110

Zhang C, Zhao G, Chen H, Guan Y, Cai H, Gao B (2013) Investigation on effects of die orifice layout on three-hole porthole extrusion of aluminum alloy 6063 tubes. JMEPEG 22:1223–1232

Xue X, Vincze G, Pereira AB, Pan J, Liao J (2018) Assessment of metal flow balance in multi-output porthole hot extrusion of AA6060 thin-walled profile. Metals 8:462

Xianghong W, Guoqun Z, Yiguo L, Xinwu M (2006) Numerical simulation and die structure optimization of an aluminum rectangular hollow pipe extrusion process. Mater Sci Eng, A 435–436:266–274

Negozio M, Pelaccia R, Donati L, Reggiani B, Tomesani L, Pinter T (2020) FEM validation of front end and back end defects evolution in AA6063 and AA6082 aluminum alloys profiles. Procedia Manufacturing 47:202–208

Kim YT, Ikeda K (2000) Flow behavior of billet surface layer in porthole die extrusion of aluminum. Metall Mater Trans A 31(6):1635–1643

Saha P (2008) Quality issues of hollow extrusions for aerospace applications. Proc. of the 9th Extrusion Technology Seminar Florida, US

Jowett C, Adams J, Daughetee C, Lea G, Huff OA, Fossl N (2008) Scrap allocation. In the Proc. of the 9th Extrusion Technology Seminar Florida, USA

Hatzenbichler T, Buchmayr B (2010) Finite element method simulation of internal defects in billet-to-billet extrusion. Proc IMechE 224 Part B

Gagliardi F, Schwane M, Citrea T, Haase M, Khalifa NB, Tekkaya AE (2014) Bridge design influences on the pressure conditions in the welding chamber for porthole die extrusion. Key Eng Mater 622–623:87–94

Mahmoodkhani Y, Wells MA, Parson N, Poole WJ (2014) Numerical modelling of the material flow during extrusion of aluminum alloys and transverse weld formation. J Mater Process Technol 688– 700

Li Y, Chen L, Tang J, Zhao G, Zhang C (2018) Effects of asymmetric feeder on microstructure and mechanical properties of high strength Al-Zn-Mg alloy by hot extrusion. J Alloys Compd 749:293–304

Zhang C, Dong Y, Zhao Gu, Chen L (2017) Experimental and numerical investigations on transverse weld of hollow aluminum profile during porthole extrusion process. Procedia Engineering 1653–1658

Donati L, Tomesani L (2004) The prediction of seam welds quality in aluminum extrusion. J Mater Process Technol 153–154:366–373

Akeret R (1992) Extrusion welds—quality aspects are now center stage. Proc ET I:319–336

Reggiani B, Segatori A, Donati L (2013) Prediction of charge welds in hollow profiles extrusion by FEM simulations and experimental validation. Int J Adv Manuf Technol 69:1855–1872

Reggiani B, Donati L (2018) Experimental, numerical and analytical investigations on the charge weld evolution in extruded profiles. Int J Adv Manuf Technol 99:1379–1387

Kim Y, Ikeda K (2000) Flow behavior of the billet surface layer in porthole die extrusion of aluminum. Metallurgical and Materials Transactions A 31A

Bakker AJD, Werkhoven RJ, Sillekens WH, Katgerman L (2014) The origin of weld seam defects related to metal flow in the hot extrusion of aluminium alloys EN AW-6060 and EN AW-6082. J Mater Process Technol 214:2349–2358

Den Bakker AJ, Katgerman L, Van der Zwaag S (2016) Analysis of the structure and resulting mechanical properties of aluminium extrusions containing a charge weld interface. J Mater Process Technol 9–21

Akeret R, Strehmel W (1988) Control of metal flow in extrusion. Proceedings of the Fourth International Aluminium Extrusion Technology Seminar 2:357–67

Miles N, Evans G, Middleditch A (1996) Automatic bearing length assignment using the medial axis transform. Proceedings of the Sixth International Aluminium Extrusion Technology Seminar 2:161–167

Miles N, Evans G, Middleditch A (1997) Bearing length for extrusion dies: rational, current practice and requirements for automation. J Mater Process Technol 72:162–176

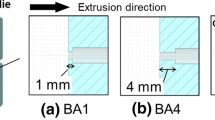

Mahmoodkhani Y, Chen J, Wells MA, Poole WJ, Parson NC (2019) The effect of die bearing geometry on surface recrystallization during extrusion of an Al-Mg-Si-Mn Alloy. Metall Mater Trans A 50A

Parson N, Jowett C (2012) The influence of die bearing geometry on surface recrystallisation of 6xxx Extrusions. Extrusion Technology

Lee GA, Im YT (2002) Analysis and die design of flat die hot extrusion process 2. Numerical design of bearing lengths. Int J Mech Sci 44:935–946

Jawwad AKA, Bashir A (2011) A comprehensive model for predicting profile exit temperature of industrially extruded 6063 aluminum alloy. Mater Manuf Processes 26:193–201

Zhang C, Yang S, Zhang Q, Zhao G, Lu P, Sun W (2017) Automatic optimization design of a feeder extrusion die with response surface methodology and mesh deformation technique. Int J Adv Manuf Technol 91:3181–3193

Zhou J, Li L, Mo J, Zhou J, Duszczyk J (2009) Prediction of the extrusion load and exit temperature using artificial neural networks based on FEM simulation [J]. Key Eng Mater 424:241–248

Li YY, Bridgwater J (2000) Prediction of extrusion pressure using an artificial neural network. Powder Technol 108:65–73

Gagliardi F, Ambrogio G, Filice L (2012) On the die design in AA6082 porthole extrusion [J]. CIRP Annals-Manufacturing Technology 231–234

Jawwad AKA, Barghash MA (2013) Evaluating the effects of process parameters on maximum extrusion pressure using a new arti-ficial neural network (ANN-based) partial-modeling technique [J]. Int J Adv Manuf Technol 2547–2564

Hsiang SH, Kuo JL, Yang FY (2006) Using artificial neural networks to investigate the influence of temperature on hot extrusion ofAZ61 magnesium alloy. J Intell Manuf 17:191–201

Zhang C, Zhao G, Chen H, Guan Y, Li H (2012) Optimization of an aluminum profile extrusion process based on Taguchi’s method with S/N analysis. Int J Adv Manuf Technol 60:589–599

Jawwad AK, Barghash M (2013) Evaluating the effects of process parameters on maximum extrusion pressure using a new artificial neural network-based (ANN-based) partial-modeling technique. Int J Adv Manuf Technol 68:2547–2564

Zhou J, Li L, Mo J, Zhou J, Duszczyk J (2010) Prediction of the extrusion load and exit temperature using artificial neural networks based on FEM simulation. Key Eng Mater 424:241–248

Bingöl S, Ayer Ö, Altinbalik T (2015) Extrusion load prediction of gear-like profile for different die geometries using ANN and FEM with experimental verification. Int J Adv Manuf Technol 76:983–992

Mayavarama R, Sajja U, Secli C, Niranjan S (2013) Optimization of bearing lengths in aluminum extrusion dies. 8th CIRP Conference on Intelligent Computention in Manuf Eng 276–281

Lucignano C, Montanari R, Tagliaferri V, Ucciardello N (2010) Artificial neural networks to optimize the extrusion of an aluminium alloy. J Intell Manuf 21:569–574

Butdee S (2012) Adaptive Aluminum Extrusion Die Design Using Case-Based Reasoning and Artificial Neural Networks. Adv Mat Res 383–390:6747–6754

Saha PK (2000) Aluminum extrusion technology. OH: ASM Int Materials Par

Zasadziński J, Libura W, Richert J (2004) Fundamentals of advanced aluminum extrusion processes. Proceedings of the 8th International Extrusion Technology Seminar 2:391–7

Klaus A (2016) How to benefit from isothermal extrusion. Proceedings of the 11th International Extrusion Technology Seminar 2:215–20

Stratton P (2008) Raising productivity of aluminum extrusion with nitrogen. International Heat Treatment and Surface Engineering 2(3–4):105–108

Ward TJ, Kelly RM, Jones GA, Heffron JF (1984) Effects of nitrogen - liquid and gaseous - on aluminum extrusion. J Miner Met Mater Soc (JOM) 36(12):29–33

Ruppin D, Mueller K (1982) Influence of mandrel cooling in the direct extrusion of aluminum tubing using stationary or moving mandrels. Aluminum Dusseldorf 58(7):402–406

He Z, Wang H, Wang M, Li G (2012) Simulation of extrusion process of complicated aluminum profile and die trial. Transactions of Nonferrous Metals Society of China 22(7):1732–1737

Zhang C, Zhao G, Chen Z, Chen H, Kou F (2012) Effect of extrusion stem speed on extrusion process for a hollow aluminum profile. Mater Sci Eng B 177(19):1691–1697

Liu G, Zhou J, Duszczyk J (2008) FE analysis of metal flow and weld seam formation in a porthole die during the extrusion of a magnesium alloy into a square tube and the effect of ram speed on weld strength. J Mater Process Technol 185–98

Mazur M, Brincat P, Leary M, Brandt M (2017) Numerical and experimental evaluation of a conformally cooled H13 steel injection mould manufactured with selective laser melting. Int J Adv Manuf Technol 93(1–4):881–900

Armillotta A, Baraggi R, Fasoli S (2014) SLM tooling for die casting with conformal cooling channels. Int J Adv Manuf Technol 71:573–583

Reggiani B, Donati L (2019) Prediction of liquid nitrogen die cooling effect on the extrusion process parameters by means of FE simulations and experimental validation. J Manuf Process 41:231–241

Pelaccia R, Negozio M, Donati L, Reggiani B, Tomesani L (2020) Efficiency of Conformal Cooling Channels Inserts for Extrusion Dies Riccardo. Procedia Manufacturing 47:209–216

Donati L, Segatori A, Reggiani B, Tomesani L, Fazzini PAB (2012) Effect of liquid nitrogen die cooling on extrusion process conditions. Key Eng Mater 491:215–222

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Consent.

Consent for publication

Consent.

Conflicts of interest/Competing interests

The author declares no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Giarmas, E., Tzetzis, D. Optimization of die design for extrusion of 6xxx series aluminum alloys through finite element analysis: a critical review. Int J Adv Manuf Technol 119, 5529–5551 (2022). https://doi.org/10.1007/s00170-022-08694-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-08694-3