Abstract

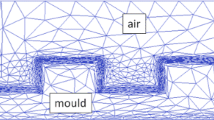

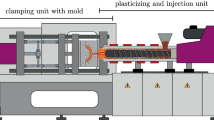

This paper suggests an original numerical investigation through a two-phase filling-stage model of microinjection moulding (μIM) of thermoplastics. An unsymmetrical stepped-part decreasing thickness was considered to perform our modelling attempts. The transient equations of mass, momentum, energy conservation, and crystallization kinetics are solved simultaneously using the Finite Element Method (FEM). Flow front advancement is tracked through the Level-set method (LSM), employing the penalty approach to deal with the mass loss problems. The significant role of the interfacial thermal contact resistance (TCR) is introduced by the thermal joint resistances approach to predict the strenuous heat transfer phenomenon along the melt–mould interface, with the presence of gap conductance. The numerical code predicted the V-shapes of the flow Fountain effect and the distinguishing flow marks due to the trapped air between the melt front and the mould. The high accuracy of the thermal joint interfacial heat transfer (htc) model and the consideration of the micro-scale features are necessary for capturing such relevant details. Model validation was performed using simulation of predicted spherulite diameters, shear rates, and layer thickness measurements. Aspects of the present work are beyond the capability of the current commercial software.

Similar content being viewed by others

Availability of data and material

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Han SR, Cho JR, Beak SK, Hong JA, Lee YS (2017) Numerical and experimental studies of injection compression molding process for thick plastic gas valve stem. Int J Adv Manuf Technol 89(1–4):651–660. https://doi.org/10.1007/s00170-016-9139-6

Xie L, Shen L, Jiang B (2011) Modelling and simulation for micro injection molding process. In Minin O (ed) Computational Fluid Dynamics Technologies and Applications, IntechOpen, pp 317–332. https://doi.org/10.5772/16283. Available from: https://www.intechopen.com/chapters/16394

Shen Y-K, Chang C-Y, Shen Y-S, Hsu S-C, Wu M-W (2008) Analysis for microstructure of microlens arrays on micro-injection molding by numerical simulation. Int Commun Heat Mass Transfer 35(6):723–727. https://doi.org/10.1016/j.icheatmasstransfer.2008.01.013

Nakhoul R, Laure P, Silva L, Vincent M (2018) A multiphase Eulerian approach for modelling the polymer injection into a textured mould. Int J Mater Form 11(1):53–66. https://doi.org/10.1007/s12289-016-1328-1

Rytka C, Lungershausen J, Kristiansen PM, Neyer A (2016) 3D filling simulation of micro- and nanostructures in comparison to iso- and variothermal injection moulding trials. J Micromech Microeng 26(6):065018. https://doi.org/10.1088/0960-1317/26/6/065018

La M, Lee JG, Park SJ (2018) Numerical and experimental investigation of plastic injection molding of micro-engineered surfaces. Polym Eng Sci 58(S1):E73–E81. https://doi.org/10.1002/pen.24652

Sardo L, Daldoul W, Vincent M, Toulorge T (2019) Simulations of heat transfer in thermoplastic injection molds manufactured by additive techniques. Int Polym Proc 34(1):37–46. https://doi.org/10.3139/217.3594

Cooper MG, Mikict BB, Yovanovich MM (1969) Thermal contact conductance. Int J Heat Mass Trans 12:279–300. http://www.mhtl.uwaterloo.ca/pdf_papers/mhtl69-2.pdf

Dawson A, Rides M, Allen CRG, Urquhart JM (2008) Polymer–mould interface heat transfer coefficient measurements for polymer processing. Polym Testing 27(5):555–565. https://doi.org/10.1016/j.polymertesting.2008.02.007

Hamasaiid A, Dargusch MS, Loulou T, Dour G (2011) A predictive model for the thermal contact resistance at liquid–solid interfaces: Analytical developments and validation. Int J Therm Sci 50(8):1445–1459. https://doi.org/10.1016/j.ijthermalsci.2011.02.016

Fu J, Ma YA (2019) A method to predict early-ejected plastic part air-cooling behavior towards quality mold design and less molding cycle time. Robot Comput Integr Manuf 56:66–74. https://doi.org/10.1016/j.rcim.2018.08.004

Delaunay D, Le Bot P, Fulchiron R, Luye JF, Regnier G (2000) Nature of contact between polymer and mold in injection molding. Part I: Influence of a non-perfect thermal contact. Polym Eng Sci 40(7):1682–1691. https://doi.org/10.1002/pen.11300

Le Goff R, Poutot G, Delaunay D, Fulchiron R, Koscher E (2005) Study and modeling of heat transfer during the solidification of semi-crystalline polymers. Int J Heat Mass Transf 48(25–26):5417–5430. https://doi.org/10.1016/j.ijheatmasstransfer.2005.06.015

Yu L, Lee LJ, Koelling KW (2004) Flow and heat transfer simulation of injection molding with microstructures. Polym Eng Sci 44(10):1866–1876. https://doi.org/10.1002/pen.20188

Somé SC, Delaunay D, Faraj J, Bailleul J-L, Boyard N, Quilliet S (2015) Modeling of the thermal contact resistance time evolution at polymer–mold interface during injection molding: Effect of polymers’ solidification. Appl Therm Eng 84:150–157. https://doi.org/10.1016/j.applthermaleng.2015.03.037

Hong S, Kang J, Yoon K (2015) Correlation between thermal contact resistance and filling behavior of a polymer melt into multi-scale cavities in injection molding. Int J Heat Mass Transf 87:222–236. https://doi.org/10.1016/j.ijheatmasstransfer.2015.03.061

Babenko M, Sweeney J, Petkov P, Lacan F, Bigot S, Whiteside B (2018) Evaluation of heat transfer at the cavity-polymer interface in microinjection moulding based on experimental and simulation study. Appl Therm Eng 130:865–876. https://doi.org/10.1016/j.applthermaleng.2017.11.022

Zhu L-Y, Wu W-Q, Jiang L, Jiang B-Y (2019) Research on influencing factors of the thermal contact resistance in thin-wall injection molding. IPP 34(1):2–8. https://doi.org/10.3139/217.3617

Weng C, Li J, Lai J, Liu J, Wang H (2020) Investigation of interface thermal resistance between polymer and mold insert in micro-injection molding by non-equilibrium molecular dynamics. Polymers 12(10):2409. https://doi.org/10.3390/polym12102409

Aalilija A, Gandin C-A, Hachem E (2021) A simple and efficient numerical model for thermal contact resistance based on diffuse interface immersed boundary method. Int J Therm Sci 166:106817. https://doi.org/10.1016/j.ijthermalsci.2020.106817

Whiteside BR, Martyn MT, Coates PD, Greenway G, Allen P, Hornsby P (2004) Micromoulding: Process measurements, product morphology and properties. Plast, Rubber Compos 33(1):11–17. https://doi.org/10.1179/146580104225018346

Zdanski PSB, Vaz M (2006) Polymer melt flow in plane channels: Effects of the viscous dissipation and axial heat conduction. Num Heat Trans Part A: Appl 49(2):159–174. https://doi.org/10.1080/10407780500302059

Pantani R, Coccorullo I, Speranza V, Titomanlio G (2005) Modeling of morphology evolution in the injection molding process of thermoplastic polymers. Prog Polym Sci 30(12):1185–1222. https://doi.org/10.1016/j.progpolymsci.2005.09.001

Boutaous M, Otmani RE, Benhadid H (2013) Conservative level set method without re-initialization process: Application to multiphase flows. Int J Model Simul 33(3):162–172. https://doi.org/10.2316/Journal.205.2013.3.205-5814

Schneider W, Köppel A, Berger J (1988) Non-isothermal crystallization, crystallization of polymers. Int Polym Proc 2(3–4):151–154. https://doi.org/10.3139/217.880150

van Krevelen DW, te Nijenhuis K (2009) Properties of polymers: Their correlation with chemical structure: Their numerical estimation and prediction from additive group contributions. Elsevier Science, Amsterdam. https://doi.org/10.1016/B978-0-08-054819-7.00033-9

Cao W, Kong L, Li Q, Ying J, Shen C (2011) Model and simulation for melt flow in micro-injection molding based on the PTT model. Modelling Simul Mater Sci Eng 19(8):085003. https://doi.org/10.1088/0965-0393/19/8/085003

Kim S-W, Turng L-S (2004) Developments of three-dimensional computer-aided engineering simulation for injection moulding. Modelling Simul Mater Sci Eng 12(3):S151–S173. https://doi.org/10.1088/0965-0393/12/3/S07

Mu Y, Zhao G, Chen A, Wu X (2012) Numerical investigation of the thermally and flow induced crystallization behavior of semi-crystalline polymers by using finite element–finite difference method. Comput Chem Eng 46:190–204. https://doi.org/10.1016/j.compchemeng.2012.06.026

Yovanovich MM (1981) New contact and gap conductance correlations for conforming rough surfaces. Proc of AIAA 16th Thermophysics Conference, Palo Alto, CA (Paper No. 81–1164). https://doi.org/10.2514/6.1981-1164

Yovanovich MM, Culham JR, Teerstra P (1997) Calculating interface resistance. Electron Cool 3(24):1–9. http://www.mhtl.uwaterloo.ca/pdf_papers/mhtl97-4.pdf

Haagh GAAV, Zuidema H, van de Vosse FN, Peters GWM, Meijer HEH (1997) Towards a 3-D finite element model for the gas-assisted injection moulding process. IPP 12(3):207–215. https://doi.org/10.3139/217.970207

Benayad A, El Otmani R, El Hakimi A, Boutaous M, Touache A, Musa KR et al (2021) Experimental investigation and numerical simulation of the microinjection molding process through an expanding flow configuration. Polym Adv Technol 32(4):1690–1711. https://doi.org/10.1002/pat.5206

El Otmani R, Zinet M, Boutaous M, Benhadid H (2011) Numerical simulation and thermal analysis of the filling stage in the injection molding process: Role of the mold-polymer interface. J Appl Polym Sci 121(3):1579–1592. https://doi.org/10.1002/app.33699

Anass B, M’hamed B, Rabie EO, Abdelhadi EH, Abdelhamid T, Musa KR et al (2020) Simulation of crystallization evolution of Polyoxymethylene during microinjection molding cycle. Polym Adv Technol 31(4):838–852. https://doi.org/10.1002/pat.4819

Chu J-S, Kamal MR, Derdouri A, Hrymak A (2012) Morphology development in the gate region of microinjection-molded thermoplastics. Polym Eng Sci 52(4):787–794. https://doi.org/10.1002/pen.22143

Yoshii M, Kuramoto H, Kato K (1993) Experimental study of transcription of smooth surfaces in injection molding. Polym Eng Sci 33(19):1251–1260. https://doi.org/10.1002/pen.760331905

Tredoux L, Satoh I, Kurosaki Y (1999) Investigation of wave-like flow marks in injection molding: Flow visualization and micro-geometry. Polym Eng Sci 39(11):2233–2241. https://doi.org/10.1002/pen.11611

Tredoux L, Satoh I, Kurosaki Y (2000) Investigation of wavelike flow marks in injection molding: a new hypothesis for the generation mechanism. Polym Eng Sci 40(10):2161–2174. https://doi.org/10.1002/pen.11348

Kamal MR, El Otmani R, Derdouri A, Chu J-S (2017) Flow and thermal history effects on morphology and tensile behavior of Poly(oxymethylene) micro injection molded parts. IPP 32(5):590–605. https://doi.org/10.3139/217.3472

Zinet M, El Otmani R, Boutaous M, Chantrenne P (2010) Numerical modeling of non-isothermal polymer crystallization kinetics: Flow and thermal effects. Polym Eng Sci 50(10):2044–2059. https://doi.org/10.1002/pen.21733

Kamal MR, Chu J, Derdouri S, Hrymak A (2010) Morphology of microinjection moulded polyoxymethylene. Plast Rubber Compos 39(7):332–341. https://doi.org/10.1179/174328910X12691245470518

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Consent of participate

We are agreeing to participate.

Consent for publication

We are agreeing to publish this work.

Conflicts of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ben Ayad, A., El Otmani, R., El Hakimi, A. et al. Numerical simulation of flow and thermal behaviour of polymer under microinjection moulding process: role of the thermal joint model at the mould–melt interface. Int J Adv Manuf Technol 119, 7429–7447 (2022). https://doi.org/10.1007/s00170-022-08682-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-08682-7