Abstract

Bill of material (BOM), as the core data in the complete life cycle management of complex products, is the primary data that supports the deep integration of intelligent and information technology of complex products. They are aiming at the characteristics of high complexity, solid dynamics, and many uncertain factors in the BOM reconstruction process of complex products. The digital twin technology is introduced into the BOM reconstruction process, and the BOM consistency reconstruction mechanism of complex products is constructed. The sequence process of BOM data flow is analyzed. The focus is on the reconstruction process of engineering BOM (EBOM), process BOM (PBOM), manufacturing BOM (MBOM), and maintenance BOM (WBOM) based on digital twin. The rationality of the constructed BOM is verified by establishing a virtual model, which promotes continuous optimization and improvement of the BOM. This paper also discusses the key technologies of data dynamic perception, digital threading, simulation modeling decoupling, and coupling in the process of BOM reconstruction. Finally, the feasibility of the proposed method is verified by combining the BOM reconstruction process of an enterprise bogie and the construction of the bogie twin system, which provides a reference for improving the accuracy, integrity, and consistency of the BOM reconstruction process of complex products.

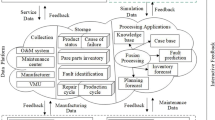

source data dynamic perception method in BOM reconstruction process

Similar content being viewed by others

References

Zhong XY, Xu X, Eberhard K, Stephen TN (2017) Intelligent manufacturing in the context of industry 4.0: a review. Engineering 3(5):96–127. https://doi.org/10.1016/J.ENG.2017.05.015

Qi QL, Tao F, Zuo Y, Zhao DM (2018) Digital twin and big data towards smart manufacturing and industry 4.0: 360 Degree Comparison. IEEE Access 06:3585–3593. https://doi.org/10.1016/j.procir.2018.03.103

Elisa N, Luca F, Marco M (2017) A review of the roles of digital twin in CPS-based production systems. Procedia Manuf 11:939–948. https://doi.org/10.1016/j.promfg.2017.07.198

Li H, Wang HQ, Cheng Y, Tao F, Hao B, Wang XC, Ji YJ, Song WY, Du WL, Wen XY, Gong XY, Li K, Zhang YF, Luo GF, Li QF (2020) Technology and application of data-driven intelligent services for complex products. Chin Mech Eng 31(07):757–772. https://doi.org/10.3969/j.issn.1004-132X.2020.07.001

Li H, Li QF, Du WL (2017) An information integration modeling method of the complex product MRO service based on service BOM. Manuf Technol Mach Tool (10):124–129. https://doi.org/10.19287/j.cnki.1005-2402.2017.10.028

Zhou CL, Liu XB, Xue FH, Bo HG, Li K (2018) Research on static service BOM transformation for complex products. Adv Eng Info 36:146–162. https://doi.org/10.1016/j.aei.2018.02.008

Chen J, Wang GF, Xue T, Li T (2020) An improved polychromatic graphs-based BOM multi-view management and version control method for complex products. Math Biosci Eng MBE 18(1):712–726. https://doi.org/10.3934/MBE.2021038

Liu M, Lai JB, Shen WM (2014) A method for transformation of engineering bill of materials to maintenance bill of materials. Robotics and Computer Integrated Manufacturing 30(2):142–149. https://doi.org/10.1016/j.rcim.2013.09.008

Jing F, Yang W, Zhang YG, Zhou R, Gao XH (2020) Dynamic BOM construction technology and application based on MBD. J Phys Conf Ser 1486(07). https://doi.org/10.1088/1742-6596/1486/7/072050

Ren GQ, Zhang L, Wang JM (2010) Data provenance tracking of BOM in maintenance phase of product. Comput Integr Manuf Syst 16(10):2187–2195. https://doi.org/10.13196/j.cims.2010.10.175.rengq.037

Zeng FH, Zhou D, Guo G (2010) Bill of material management based on knowledge engineering. Comput Integr Manuf Syst 16(9):1977–1983. https://doi.org/10.13196/j.cims.2010.09.187.zengfh.018

Tao F, Zhang M, Liu Y, Nee AYC (2018) Digital twin driven prognostics and health management for complex equipment. CIRP Ann 67(1):169–172. https://doi.org/10.1016/j.cirp.2018.04.055

Eric JT, Anthony RI, Thomas GE, Spottswood SM (2011) Reengineering aircraft structural life prediction using a digital twin. Int J Aerospace Eng 2011. https://doi.org/10.1155/2011/154798

Mintchell G (2015) GE, the digital thread, the digital twin, the digital company [EB/OL]. (2015–10–07) [2021–04–14]. http://themanufacturingconnection.com/2015/10/ge-the-digital-thread-the-digital-twin-thedigital-company/

Fourgeau E, Gomez E, Adli H, Fernandes C, Hagege M (2016) System engineering workbench for multi-views systems methodology with 3D experience platform. The Aircraft radar use case. Complex systems design & management Asia: smart nations-sustaining and designing, CSD & M Asia 426:269–270. https://doi.org/10.1007/978-3-319-29643-2_21

SIEMEN (2018-06-23) Digital Twin [EB/OL] [2021–04–14]. https://new.siemens.com/global/zh/products/automation/systems/sinumerik-one/digital-twin.html

SIEMENS(2019-03-24) Electrical Digital Twin [EB/OL] [2021–09–11]. https://new.siemens.com/global/en/products/energy/energy-automation-and-smart-grid/electrical-digital-twin.html

Arif FM, Tolga E, Dilara D (2021) Digital Twin in the Military Field. IEEE Internet Computing 1. https://doi.org/10.1109/MIC.2021.3055153

DNVGL (2019-01-23) Digital twins and sensor monitoring [EB/OL] [2021–09–04]. https://www.dnv.com/expert-story/maritime-impact/Digital-twins-and-sensor-monitoring.html

Dr. HEMPEL (2017-12-19) Healthcare solution testing for future | Digital Twins in healthcare [EB/OL] [2021–09–01]. https://www.dr-hempel-network.com/digital-health-technolgy/digital-twins-in-healthcare/

Tao F, Zhang M, Cheng JF, Qi QL (2017) Digital twin workshop: a new paradigm for future workshop. Comput Integr Manuf Syst 23(1):1–9. https://doi.org/10.13196/j.cims.2017.01.001

Tao F, Liu WR, Zhang M, Hu TL, Qi QL, Zhang H, Sui FY, Wang T, Xu H, Huang ZG, Ma X, Zhang LC, Cheng JF, Yao NK, Yi WM, Zhu KZ, Zhang XS, Meng FJ, Jin XH, Liu ZB, He LR, Cheng H, Zhou EZ, Li Y, Lv Q, Luo YM (2019) Five-dimension digital twin model and its ten applications. Comput Integr Manuf Syst (01):1–18. https://doi.org/10.13196/j.cims.2019.01.001

Söderberg R, Wärmefjord K, Johan SC, Lindkvist L (2017) Toward a digital twin for real-time geometry assurance in individualized production. CIRP Annals - Manuf Technol 66(1):137–140. https://doi.org/10.1016/j.cirp.2017.04.038

Benjamin S, Nabil A, Luc M, Sandro W (2017) Shaping the digital twin for design and production engineering. CIRP Annals - Manuf Technol 66(1):141–144. https://doi.org/10.1016/j.cirp.2017.04.040

Vachálek J, Bartalský L, Rovný O, Šišmišová D (2017) The digital twin of an industrial production line within the industry 4.0 concept. 2017 21st International Conference on Process Control (PC): 258–262. https://doi.org/10.1109/PC.2017.7976223

Greyce NS, Charles S, Carlos EP, Danubia BE (2016) Digital twin data modeling with AutomationML and a communication methodology for data exchange. IFAC PapersOnLine 49(30):12–17. https://doi.org/10.1016/j.ifacol.2016.11.115

Tao F, Cheng Y, Cheng JF, Zhang M, Xu WJ, Qi QL (2017) Theories and technologies for cyber-physical fusion in digital twin shop-floor. Comput Integr Manuf Syst 23(08):1603–1611. https://doi.org/10.13196/j.cims.2017.08.001

Pang TY, Pelaez RJD, Cheng CT, Yasin A, Lim H, Miletic M (2021) Developing a digital twin and digital thread framework for an Industry 4.0 shipyard. Appl Sci 11(3):1097–1097. https://doi.org/10.3390/app11031097

China Electronics Standardization Institute. Digital twin application white paper [EB/OL]. [2020–11–18]. [2021–5–7]. https://www.cesi.cn/202011/7002.html

Acknowledgements

The authors wish to acknowledge support from Staff of Industrial Engineering Project Team, School of Mechanical Engineering, Xi'an University of Science and Technology.

Funding

This work was supported by the [National Key Research and Development Program Project Fund of China #1] under Grant [number 2018YFB1703402].

Author information

Authors and Affiliations

Contributions

All authors contributed equally to the generation and analysis of experimental data and the development of the manuscript.

Corresponding author

Ethics declarations

Ethics approval

All authors declare that this article does not have any academic ethics issues and strictly follows the journal submission rules.

Consent to participate

All authors agree to participate in the research work of this paper and publish it in the International Journal of Advanced Manufacturing Technology.

Consent for publication

All authors agree to publish this article in the International Journal of Advanced Manufacturing Technology.

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Y., Ren, W., Zhang, C. et al. Bill of material consistency reconstruction method for complex products driven by digital twin. Int J Adv Manuf Technol 120, 185–202 (2022). https://doi.org/10.1007/s00170-021-08603-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08603-0