Abstract

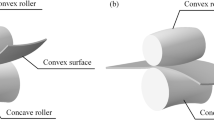

The 3D curved parts rolling based on rigid arc-shaped rollers is a novel plastic forming process for rapidly manufacturing curved parts with double curvature. This work proved that the method can form different types of 3D curved parts through small adjustments of the rolling reduction without replacing the rollers. The study found that when the generatrix radius of the convex roller is smaller than that of the concave roller, the distribution rule of uneven roll gap could vary with the change of the rolling reduction. Therefore, the forming method can change the distribution rule of uneven roll gaps by adjusting the rolling reduction to form different types of curved parts (spherical parts, saddle-shaped parts, or cylindrical parts). The relationship between the rolling reduction and the distribution rule of roll gaps is studied by analytical, finite element, and experiment method. And the influence of the rolling reduction on the bending deformation of different types of curved parts is studied. The research results show that the longitudinal bending deformation of formed curved parts is greatly affected by the rolling reduction. The longitudinal curvature of formed saddle-shaped parts decreases with the increase of the rolling reduction, and the longitudinal curvature of formed spherical parts increases with the increases of the rolling reduction. The transverse bending deformation of formed curved parts is little affected by the rolling reduction.

Similar content being viewed by others

Availability of data and materials

The authors declare that the data and the materials that support the findings of this study are available within the article and from the corresponding author upon reasonable request.

References

Li MZ, Cai ZY, Sui Z, Yan QG (2002) Multi-point forming technology for sheet metal. J Mater Process Technol 129:333–338. https://doi.org/10.1016/S0924-0136(02)00685-4

Walczyk DF, Lakshmikanthan J, Kirk DR (1998) Development of a reconfigurable tool for forming aircraft body panels. J Manuf Syst 17:287–296. https://doi.org/10.1016/S0278-6125(98)80076-9

Das B, Biswas P (2018) A Review of Plate Forming by Line Heating. J Ship Prod Des 34:155–167. https://doi.org/10.5957/jspd.170003

Russig C, Bambach M, Hirt G, Holtmann N (2013) Shot peen forming of fiber metal laminates on the example of GLARE®. Int J Mater Form 7:425–438. https://doi.org/10.1007/s12289-013-1137-8

Jackson K, Allwood J (2009) The mechanics of incremental sheet forming. J Mater Process Technol 209:1158–1174. https://doi.org/10.1016/j.jmatprotec.2008.03.025

Yamashita I, Yamakawa T (1988) Apparatus for forming plate with a double-curved surface. Parent, US 4770017

Yoon SJ, Yang DY (2003) Development of a Highly Flexible Incremental Roll Forming Process for the Manufacture of a Doubly Curved Sheet Metal. CIRP Ann-Manuf Technol 52:201–204. https://doi.org/10.1016/s0007-8506(07)60565-4

Li MZ, Hu ZQ, Cai ZY, Gong XP (2007) Method of multipoint continuous forming for the freeform surface parts. Chin J Mech Eng 43:155–159. https://doi.org/10.3321/j.issn:0577-6686.2007.12.029

Shim DS, Yang DY, Kim KH, Han MS, Chung SW (2009) Numerical and experimental investigation into cold incremental rolling of doubly curved plates for process design of a new LARS (line array roll set) rolling process. CIRP Ann-Manuf Technol 58:239–242. https://doi.org/10.1016/j.cirp.2009.03.112

Li MZ, Cai ZY, Li RJ, Lan YW, Qiu NJ (2012) Continuous forming method for three-dimensional surface parts based on the rolling process using bended roll. Chin J Mech Eng 48:44–49. https://doi.org/10.3901/jme.2012.14.044

Li RJ, Li MZ, Qiu NJ, Cai ZY (2014) Surface flexible rolling for three-dimensional sheet metal parts. J Mater Process Technol 214:380–389. https://doi.org/10.1016/j.jmatprotec.2013.09.008

Li Y, Fu WZ, Li MZ, Liu XD, Sun S, Yi Z (2018) Influence of deformation path on the forming effect in a multistep flexible rolling process. Int J Miner Metall Mater 25:1173–1180. https://doi.org/10.1007/s12613-018-1669-5

Liu P, Ku TW, Kang BS (2015) Shape error prediction and compensation of three-dimensional surface in flexibly-reconfigurable roll forming. J Mech Sci Technol 29:4387–4397. https://doi.org/10.1007/s12206-015-0937-9

Yoon JS, Kim J, Kang BS (2016) Deformation analysis and shape prediction for sheet forming using flexibly reconfigurable roll forming. J Mater Process Technol 233:192–205. https://doi.org/10.1016/j.jmatprotec.2016.02.005

Park JW, Yoon J, Lee K, Kim J, Kang BS (2017) Rapid prediction of longitudinal curvature obtained by flexibly reconfigurable roll forming using response surface methodology. Int J Adv Manuf Technol 91:3371–3384. https://doi.org/10.1007/s00170-017-9999-4

Ghiabakloo H, Kim J, Kang BS (2018) An efficient finite element approach for shape prediction in flexibly-reconfigurable roll forming process. Int J Mech Sci 142–143:339–358. https://doi.org/10.1016/j.ijmecsci.2018.05.005

Ghiabakloo H, Park JW, Kil MG, Lee K, Kang BS (2019) Design of the flexibly-reconfigurable roll forming process by a progressively-improving goal seeking approach. Int J Mech Sci 157–158:136–149. https://doi.org/10.1016/j.ijmecsci.2019.04.020

Wang DM, Li MZ, Cai ZY (2014) An investigation on roll adjusting radius in three-dimensional rolling process for three-dimensional surface parts. Proc Inst Mech Eng Part B-J Eng Manuf 229:761–769. https://doi.org/10.1177/0954405414530901

Wang XT, Li MZ (2020) Research on three-dimensional curved surface rolling based on rigid arc-shaped rollers. Int J Adv Manuf Technol 107:805–814. https://doi.org/10.1007/s00170-020-05096-1

Chang X, Fu W, Li M, Wang X, Yang W, Deng Y (2021) An Investigation into the Effect of Rolling Reduction on 3D Curved Parts Rolling Process. METALS-BASEL 11:1209–1221. https://doi.org/10.3390/met11081209

Chang X, Fu W, Li M, Wang X (2021) The flexible rolling process of three-dimensional curved parts using an auxiliary plate based on rigid arc-shaped rollers. Int J Adv Manuf Technol 116:1103–1113. https://doi.org/10.1007/s00170-021-07512-6

Funding

This work was financially supported by the Project of Jilin Provincial Scientific and Technological Department (20150201005GX).

Author information

Authors and Affiliations

Contributions

Xiang Chang wrote this article, conducted the experiments, established the finite element model, processed the numerical and experimental data, and analyzed the results. Wenzhi Fu provided valuable suggestions on the study, and was responsible for guiding the work. Mingzhe Li proposed the new forming method, theoretically demonstrated the feasibility of this method, provided valuable suggestions on the study, and was responsible for guiding the work. Xintong Wang provided valuable suggestions, and helped to complete the experiments. Weifeng Yang helped to complete the experiments. Yushan Deng provided valuable suggestions on the study and was responsible for guiding the work. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

The manuscript has not been submitted or published anywhere. It will not be submitted elsewhere as well.

Consent to participate

All authors consent to participate in the author team of this submitted manuscript.

Consent to publish

The manuscript was approved by all authors to publish.

Competing interests

The authors declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chang, X., Fu, W., Li, M. et al. Research on rolling different types of 3D curved parts by small adjustments in rolling reduction. Int J Adv Manuf Technol 119, 6235–6244 (2022). https://doi.org/10.1007/s00170-021-08519-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08519-9