Abstract

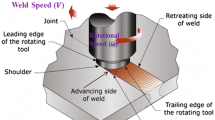

Friction stir welding (FSW) is a solid-state jointing technology, and has the advantages of high joint strength, low residual stress, and small deformation after welding. During FSW, the welding temperature directly influences the quality of the weldment. A heat generation model of FSW medium thickness aluminum alloy 2219 is established considering the friction heat generated at the interface between the tool and the workpiece and the plastic deformation heat of the weldment material near the tool. The heat transfer model is set considering heat conduction, convection, and radiation. Using JMatPro technology, temperature-related material parameters of aluminum alloy 2219 are obtained. The built heat generation model is imported into the simulation software ABAQUS through the DFLUX subroutine, and the simulation of FSW process is achieved. The effectiveness of the simulation is verified by FSW experiments. The simulation has high prediction accuracy. Based on the simulation, the influence of welding parameters on temperature distribution is explored; subsequently the influence of welding temperature on mechanical properties of welded joint is also studied. The research guides the prediction of the temperature distribution and the improvement of the mechanical performance of FSW medium thickness aluminum alloy 2219.

Similar content being viewed by others

Availability of data and material

All data generated or analyzed during this study are included in this manuscript.

Code availability

The code is available on request.

References

Chen J, Shi L, Wu C, Jiang Y (2021) The effect of tool pin size and taper angle on the thermal process and plastic material flow in friction stir welding. Int J Adv Manuf Technol 116(9–10):2847–2860. https://doi.org/10.21203/rs.3.rs-335152/v1

Sarikavak Y (2021) An advanced modelling to improve the prediction of thermal distribution in friction stir welding (FSW) for difficult to weld materials. J Braz Soc Mech Sci 43:4. https://doi.org/10.1007/s40430-020-02735-2

Hidetoshi F, Yufeng S, Hideaki K (2011) Microstructure and mechanical properties of friction stir welded pure Mo joints. Scr Mater 64(7):657–660. https://doi.org/10.1016/j.scriptamat.2010.12.014

McClure JC, Tang W, Murr LE, Gould JE (1998) A thermal model of friction stir welding. ASM Proc Int Conf Trends Weld Res 590–595

Russell MJ, Shercliff HR (1999) Analytical modelling of friction stir welding. In Russell MJ, Shercliff R, editors. INALCO’98: seventh international conference on joints in aluminium. Cambridge, UK: TWI; 197–207

Song M, Kovacevic R (2003) Thermal modeling of friction stir welding in a moving coordinate system and its validation. Int J Adv Manuf Technol 43(6):605–615. https://doi.org/10.1016/S0890-6955(03)00022-1

Chang WS, Bang HS, Jung SB, Yun MY, Lee WB (2003) Joint properties and thermal behaviors of friction stir welded age hardenable 6061Al alloy//Materials Science Forum. Trans Tech Publications Ltd. Zurich-Uetikon, Switzerland 426:2953–2958. https://doi.org/10.4028/www.scientific.net/MSF.426-432.2953

Frigaard O, Grong O, Midling OT (2001) A process model for friction stir welding of age hardening aluminum alloys. Metall Mater Trans A Phys Metall Mater Sci 32(5):1189–1200. https://doi.org/10.1007/s11661-001-0128-4

Kiral BG, Tabanolu M, Serindag HT (2013) Finite element modeling of friction stir welding in aluminum alloys joint. Math Comput Appl 18(2):122–131. https://doi.org/10.3390/mca18020122

Schmidt H, Hattel J, Wert J (2004) An analytical model for the heat generation in friction stir welding. Model Simul Mat Sci Eng 12(1):143–157. https://doi.org/10.1088/0965-0393/12/1/013

Gadakh VS, Adepu K (2013) Heat generation model for taper cylindrical pin profile in FSW. J Mater Res Technol 2(4):370–375. https://doi.org/10.1016/j.jmrt.2013.10.003

Yaduwanshi DK, Bag S, Pal S (2015) Heat transfer analyses in friction stir welding of aluminium alloy. Proc Inst Mech Eng B J Eng Manuf 229(10):1722–1733. https://doi.org/10.1177/0954405414539297

Ghetiya ND, Patel KM (2018) Numerical simulation on an effect of backing plates on joint temperature and weld quality in air and immersed FSW of AA2014-T6. Int J Adv Manuf Technol 99(5):1937–1951. https://doi.org/10.1007/s00170-018-2632-3

Bonifaz EA (2019) A new thermal model in SAE-AISI 1524 friction stir welding. Defect Diffus Forum 390:53–63. https://doi.org/10.4028/www.scientific.net/DDF.390.53

Liu XQ, Yu Y, Yang SL, Liu HJ (2020) A modified analytical heat source model for numerical simulation of temperature field in friction stir welding. Adv Mater Sci Eng 11:1–16. https://doi.org/10.1155/2020/4639382

Canaday CT, Moore MA, Wei T, Reynolds AP (2013) Through thickness property variations in a thick plate AA7050 friction stir welded joint. Mater Scie Eng A 559:678–682. https://doi.org/10.1016/j.msea.2012.09.008

Aziz SB, Dewan MW, Huggett DJ, Wahab MA, Okeil AM, Liao TW (2018) A fully coupled thermomechanical model of friction stir welding (FSW) and numerical studies on process parameters of lightweight aluminum alloy joints. Acta Metall Sin 31(1):1–18. https://doi.org/10.1007/s40195-017-0658-4

Zhang ZQ, Jiang ZL, Wei QY (2017) Dynamic mechanical properties and constitutive equations of 2219 aluminum alloy. J Mater Eng 45(10):47–51. https://doi.org/10.11868/j.issn.1001-4381.2016.000859

Batool A, Anjum NA, Khan MY (2021) Impact of pin tool designs on the mechanical properties and microstructure of aluminum alloys AA7075-AA6061. J Chin Inst Eng 44(7):683–693. https://doi.org/10.1080/02533839.2021.1940293

Meng TY, Deng QH, You F, Wu Y, Chen K (2020) Research on single-side high speed friction stir welding of 6005A–T6 aluminum alloy thick plate. Weld Technol 49(10):43–46. https://doi.org/10.13846/j.cnki.cn12-1070/tg.2020.10.014

He DQ, Zhao ZF, Lai RL, Yang KY (2018) Research on the microstructure and mechanical properties of ultrasonic assisted friction stir welding joints of 2219–T87 aluminum alloy. J Hunan Univ Nat Sci 45(4):41–47. https://doi.org/10.16339/j.cnki.hdxbzkb.2018.04.006

Funding

The research was supported by the National Key Research and Development Program of China (Grant No. 2019YFA0709003), the Dalian Science and Technology Innovation Fund (Grant No. 2020JJ26GX041), and the Fundamental Research Funds for the Central Universities (Grant No. DUT20ZD204. The financial contributions are gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

Xiaohong Lu: Conceptualization, Supervision, Methodology, Funding acquisition, Project administration. Yihan Luan: Conceptualization, Methodology, Software, Validation, Writing-original draft, Investigation, Writing-review and editing. Xiangyue Meng: Formal analysis, Data curation. Yu Zhou: Software, Investigation. Ning Zhao: Formal analysis. Steven Y. Liang: Resources.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

The authors’ consent that the work entitled as “Temperature distribution and mechanical properties of FSW medium thickness aluminum alloy 2219” for possible publication in International Journal of Advanced Manufacturing Technology.

Conflict of interest/competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lu, X., Luan, Y., Meng, X. et al. Temperature distribution and mechanical properties of FSW medium thickness aluminum alloy 2219. Int J Adv Manuf Technol 119, 7229–7241 (2022). https://doi.org/10.1007/s00170-021-08505-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08505-1