Abstract

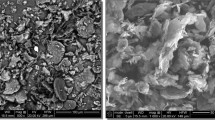

In this work, the influence of the location of the electrodes on the productivity of electrochemical process and specific energy consumption during direct current electrosynthesis of finely dispersed graphite powder is considered. The authors consider the possibility of using finely dispersed graphite powder obtained by electrolysis as the main component of a multifunctional aerospace coating. For this purpose, two types of devices were constructed: with a coaxial and parallel arrangement of the electrodes. The main elements of the device are a stainless steel cathode and a graphite anode immersed in electrolyte (an aqueous solution of salts). The authors consider the influence of the arrangement of the electrodes in the installation for direct current electrosynthesis from the point of view of the energy efficiency and productivity of electrochemical process. As a result of anodic oxidation, a fine powder from graphite of the MPG-6 brand was obtained. The size of the resulting graphite particles is 1–50 µm. This finely dispersed graphite powder can be used as the main component of a multifunctional coating in aircraft, since it has an even homogeneous structure, as well as higher values of the main mechanical properties of a multifunctional coating, which will lead to a decrease in the number of layers and the thickness of the coating applied. The resulting graphite powder can also be used in the production of fire-retardant and heat-insulating materials for the chemical, nuclear industry, instrumentation, and heat power engineering.

Similar content being viewed by others

Availability of data and material

Materials are commercially available at a reasonable cost, and the quality result was obtained.

Code availability

Not applicable.

Abbreviations

- C (C4 +):

-

Carbon (carbon ions)

- Cl¯:

-

Chloride ion

- Cl2 :

-

Chlorine gas

- CO2 :

-

Carbon dioxide (carbonic acid gas)

- DC:

-

Direct current

- e¯:

-

Electron

- H2 :

-

Dihydrogen

- H2O:

-

Hydrogen oxide

- K (K+):

-

Potassium (potassium ion)

- KCl:

-

Potassium chloride

- MgCl2 :

-

Magnesium chloride

- MPG-6:

-

Brand of graphite (graphite has a fine-grained structure)

- Na (Na+):

-

Sodium (sodium ion)

- NaCl:

-

Sodium chloride

- O2 :

-

Molecular oxygen

- OH¯:

-

Hydroxide

- SEM:

-

Scanning electron microscope

- A :

-

Cm2, area of the working surface of the anode

- e :

-

KJ/g, specific energy consumption

- E :

-

V/m, electric field strength

- I :

-

A, electric current

- j :

-

A/m2, current density

- ĵ :

-

A/m2, average current density

- m :

-

G, mass of the obtained fine graphite powder

- r :

-

Mm, distance of a given point in the electrolyte

- r 1 :

-

Mm, distance from center of anode to extreme surface of cathode

- r 0 :

-

Mm, radius of the anode

- t :

-

Min, time of electrosynthesis

- T :

-

°C, temperature electrolyte

- u :

-

G/min × cm2, productivity of electrosynthesis

- V :

-

V, voltage during electrosynthesis

- V a :

-

Ml, anode space volume

- V c :

-

Ml, cathode space volume

- V e :

-

Ml, electrolyte volume

- x, y, n :

-

Coefficients depending on the oxidation state of carbon.

- σ i :

-

%, Volume concentration

References

Shestakov IY, Kupryashov AV, Utenkov VD, Remizov IA (2020) Production of finely dispersed powder from graphite by electrolysis. Siberian Journal of Science and Technology 21(4):574–580. https://doi.org/10.31772/2587-6066-2020-21-4-574-580

Tiwary A, Kumar R, Chohan JS (2021) A review on characteristics of composite and advanced materials used for aerospace applications. Journal Materials today: Proceedings. https://doi.org/10.1016/j.matpr.2021.06.276

Jothi V, Adesina AY, Kumar AM, Al-Aqeeli N, Ram JSN (2020) Influence of an anodized layer on the adhesion and surface protective performance of organic coatings on AA2024 aerospace Al alloy. Prog Org Coat 138:105396. https://doi.org/10.1016/j.porgcoat.2019.105396

Guerriero G, Alderliesten R, Dingemans T, Benedictus R (2011) Thermotropic liquid crystalline polymers as protective coatings for aerospace. Prog Org Coat 70:245–251. https://doi.org/10.1016/j.porgcoat.2010.09.027

Iqbal HMS, Bhowmik S, Benedictus R (2017) Performance evaluation of polybenzimidazole coating for aerospace application. Prog Org Coat 105:190–199. https://doi.org/10.1016/j.porgcoat.2017.01.005

Liu J, Li Z, Zhang L, Hou J, Lu Z, Zhang P, Wang B, Jin N (2019) Degradation behavior and mechanism of polyurethane coating for aerospace application under atmospheric conditions in South China Sea. Prog Org Coat 136:105310. https://doi.org/10.1016/j.porgcoat.2019.105310

Bousser E, Martinu L, Klemberg-Sapieha JE (2014) Solid particle erosion mechanisms of protective coatings for aerospace applications. Surf Coat Technol 257:165–181. https://doi.org/10.1016/j.surfcoat.2014.08.037

Ko M, Mai PL, T., Sa Y. J., Woo J., Thien Nguyen T. V., Kim J. H., Oh D., Sharma P., Ryu J., Shin T. J., Joo S. H., Kim Y. H., Jang J.-W. (2019) Unassisted solar lignin valorisation using a compartmented photo-electro-biochemical cell. Nat Commun 10:5123

Kotov SA, Muzafarova SVR, Livintsova MG (2019) The research and development of the technology for pressure treatment of the thermally expanded graphite powders. Key Eng Mater 822:284–290. https://doi.org/10.4028/www.scientific.net/KEM.822.284

Zhang Y, Qin J, Lowe SE, Li W, Zhu Y, Al-Mamun M, Batmunkh M, Qi D, Zhang S, Zhong YL (2021) Enhanced electrochemical production and facile modification of graphite oxide for cost-effective sodium ion battery anodes. Carbon 177:71–78. https://doi.org/10.1016/j.carbon.2021.02.067

Sun G, Li X, Yan H, Qiu J, Zhang Y (2008) Production of nanosized graphite powders from natural graphite by detonation. Carbon 46:476–481. https://doi.org/10.1016/j.carbon.2007.12.013

Delport MR, Badenhorst H (2016) Production of a self-adhering mesophase powder from anthracene oil for low pressure forming of graphite artefacts. J Mater Sci 51:6309–6318. https://doi.org/10.1007/s10853-016-9927-2

Kamali AR (2021) Black diamond powder: on the thermal oxidation and surface graphitization. Appl Surf Sci 551:149371. https://doi.org/10.1016/j.apsusc.2021.149371

Jibrael RI, Mohammed MKA (2016) Production of graphene powder by electrochemical exfoliation of graphite electrodes immersed in aqueous solution. Optik 127:6384–6389. https://doi.org/10.1016/j.ijleo.2016.04.101

Medina NF, Barbero-Barrera MM, Bustamante R (2016) Improvement of the properties of gypsum-based composites with recycled isostatic graphite powder from the milling production of molds for Electrical Discharge Machining (EDM) used as a new filler. Constr Build Mater 107:17–27. https://doi.org/10.1016/j.conbuildmat.2015.12.194

Chauhan APS, Chawla K (2016) Comparative studies on graphite and carbon black powders, and their dispersions. J Mol Liq 221:292–297. https://doi.org/10.1016/j.molliq.2016.05.043

Sajadi SM, Enayat S, Vasarhelyi L, Alabastri A, Lou M, Sassi LM, Kutana A, Bhowmick S, Durante C, Kukovecz A, Puthirath AB, Konya Z, Vajtai R, Boul P, Tiwary CS, Rahman MM, Ajayan PM (2021) Three-dimensional printing of complex graphite structures. Carbon 181:260–269. https://doi.org/10.1016/j.carbon.2021.05.003

Esmati M, Sharifi H, Raeissi M, Atrian A, Rajaee A (2019) Investigation into thermal expansion coefficient, thermal conductivity and thermal stability of Al-graphite composite prepared by powder metallurgy. J Alloy Compd 773:503–510. https://doi.org/10.1016/j.jallcom.2018.09.225

Chen Z, Lai W, Xu Y, Xie G, Hou W, Zhanchang P, Kuang C, Li Y (2021) Anodic oxidation of ciprofloxacin using different graphite felt anodes: kinetics and degradation pathways. J Hazard Mater 405:124262. https://doi.org/10.1016/j.jhazmat.2020.124262

Yao Z, Zhong Q, Xiao J, Ye S, Tang L, Wang Z (2021) Efficient separation of fluoride and graphite carbon in spent cathode carbon from aluminum electrolysis by mechanical activation assisted alkali fusion treatment. Miner Eng 161:106717. https://doi.org/10.1016/j.mineng.2020.106717

Song D, Li J, Wang Z, Zhao C (2020) Performance of graphite felt as anodes in the electro-Fenton oxidation systems: changes in catalysis, conductivity and adsorption properties. Appl Surf Sci 532:147450. https://doi.org/10.1016/j.apsusc.2020.147450

Fang J, Shijirbaatar A, Lin D-H, Wang D-J, Shen B, Sun P-D, Zhou Z-Q (2017) Stability of co-existing ZnO and TiO2 nanomaterials in natural water: aggregation and sedimentation mechanisms. Chemosphere 184:1125–1133. https://doi.org/10.1016/j.chemosphere.2017.06.097

Li Y, Zhang M, Hao R, Wang H, He X, Du T, Yang X, Wang Y (2019) Influence of (photo)bromination on the transformation, aggregation and sedimentation of graphene oxide. Chem Eng J 355:487–497. https://doi.org/10.1016/j.cej.2018.08.199

Zhao T, Fang M, Tang Z, Zhao X, Wu F, Giesy JP (2019) Adsorption, aggregation and sedimentation of titanium dioxide nanoparticles and nanotubes in the presence of different sources of humic acids. Sci Total Environ 692:660–668. https://doi.org/10.1016/j.scitotenv.2019.07.312

Ankit KV, Mishra A, Mohan S, Singh KK, Mohan A (2020) The effect of titanium carbide particles on microstructure and mechanical properties of copper/graphite composites prepared by flake powder metallurgy route. Journal Materials today: Proceedings 26:1140–1144. https://doi.org/10.1016/j.matpr.2020.02.228

Li W, Sun J, Gao Y, Zhang Y, Ouyang J, Na N (2021) Monitoring of electrochemical reactions on different electrode configurations by ambient mass spectrometry. TrAC, Trends Anal Chem 135:116180. https://doi.org/10.1016/j.trac.2021.116180

Samal S (2020) Effect of shape and size of filler particle on the aggregation and sedimentation behavior of the polymer composite. Powder Technol 366:43–51. https://doi.org/10.1016/j.powtec.2020.02.054

Yakovlev AV, Yakovleva EV, Tseluikin VN, Krasnov VV, Mostovoi AS, Rachmetulina LA, Frolov IN (2019) Electrochemical synthesis of multilayer graphene oxide by anodic oxidation of disperse graphite. Russ J Electrochem 55(12):1196–1202. https://doi.org/10.1134/S102319351912019X

Obraztsova EY, Bakunin ES, Rukhov AV, Degtyarev AA (2020) Adsorption characteristics of nanographite oxide obtained from thermally expanded graphite. Mendeleev Commun 30:174–176. https://doi.org/10.1016/j.mencom.2020.03.014

Buliyaminu IA, Aziz MA, Shah SS, Mohamedkhair AK, Yamani ZH (2020) Preparation of nano-Co3O4-coated Albizia proceraderived carbon by direct thermal decomposition method for electrochemical water oxidation. Arab J Chem 13:4785–4796. https://doi.org/10.1016/j.arabjc.2019.12.013

Szeluga U, Olszowska K, Pusz S, Myalski J, Godzierz M, Kobyliukh A, Tsyntsarski B (2021) Effect of grain fractions of crushed carbon foam on morphology and thermomechanical and tribological properties of random epoxy-carbon composites. Wear 466–467:203558. https://doi.org/10.1016/j.wear.2020.203558

Vovchenko L, Lozitsky O, Matzui L, Oliynyk V, Zagorodnii V, Skoryk M (2020) Electromagnetic shielding properties of epoxy composites with hybrid filler nanocarbon/BaTiO3. Mater Chem Phys 240:122234. https://doi.org/10.1016/j.matchemphys.2019.122234

Song Y, Zeng L, Zheng Q (2017) Unique liquid-to-solid transition of carbon filler filled polystyrene melts. Compos Sci Technol 147:39–44. https://doi.org/10.1016/j.compscitech.2017.05.003

Tang D, Zhang X, Hu S, Liu X, Ren X, Hu J, Feng Y (2020) The reuse of red brick powder as a filler in styrene-butadiene rubber. J Clean Prod 261:120966. https://doi.org/10.1016/j.jclepro.2020.120966

Werner K, Amit S, Jurk DR, Heinrich G (2010) Contribution of physico-chemical properties of interfaces on dispersibility, adhesion and flocculation of filler particles in rubber. Polymer 51(9):1954–1963. https://doi.org/10.1016/j.polymer.2010.03.013

Gao M, Wang J, Zhou Y, Morshed M, Wang Z, Zhao S (2019) Bifunctional oxygen-vacancy abundant perovskite nanosheets for improving protective performance of epoxy coatings. Prog Org Coat 137:105301. https://doi.org/10.1016/j.porgcoat.2019.105301

Hauch A, Traulsen ML, Kungas R, Skafte TL (2021) CO2 electrolysis – Gas impurities and electrode overpotential causing detrimental carbon deposition. J Power Sources 506:230108. https://doi.org/10.1016/j.jpowsour.2021.230108

Thompson JG, Gao X, Toma S, Abad K, Bhatnagar S, Landon J, Liu K (2019) Decomposition of N-nitrosamines formed in CO2 capture systems through electrochemically-mediated reduction on carbon xerogel electrode. Int J Greenhouse Gas Control 83:83–90. https://doi.org/10.1016/j.ijggc.2019.02.003

Escobar JG, Vaneckova E, Novakova LS, Vivaldi F, Heyda J, Kubista J, Shestivska V, Spanel P, Schwarzova-Peckova K, Rathousky J, Sebechlebska T, Kolivoska V (2020) The development of a fully integrated 3D printed electrochemical platform and its application to investigate the chemical reaction between carbon dioxide and hydrazine. Electrochim Acta 360:136984. https://doi.org/10.1016/j.electacta.2020.136984

Kildahl H, Li Z, Cao H, Slater P, Ding Y (2021) Carbon dioxide decomposition through gas exchange in barium calcium iron niobates. Catal Today 364:211–219. https://doi.org/10.1016/j.cattod.2020.05.024

Zhang C, Jiang YX, Sun JP, Xiao H, Shi MW, Long JJ (2020) Investigation of the influence of supercritical carbon dioxide treatment on meta-aramid fiber: thermal decomposition behavior and kinetics. J CO2 Util 37: 85–96. https://doi.org/10.1016/j.jcou.2019.10.007

Buinachev S, Mashkovtsev MA, Zhirenkina N, Aleshin D, Dankova A (2021) A new approach for the synthesis of monodisperse zirconia powders with controlled particle size. Int J Hydrogen Energy 46(32):16878–16887. https://doi.org/10.1016/j.ijhydene.2021.01.134

Liu X, Yuan Y, Liu J, Liu B, Chen X, Ding J, Han X, Deng Y, Zhong C, Hu W (2019) Utilizing solar energy to improve the oxygen evolution reaction kinetics in zinc–air battery. Nat Commun 10:4767

Jiang Y, Liang Q, Chu N, Hao W, Zhang L, Zhan G, Li D, Zeng RJ (2020) A slurry electrode integrated with membrane electrolysis for high-performance acetate production in microbial electrosynthesis. Sci Total Environ 741:140198. https://doi.org/10.1016/j.scitotenv.2020.140198

Arredondo CH, Aguilar-Lira G, Perez-Silva I, Rodriguez JA, Islas G, Hernandez P (2019) Characterization and application of Agave salmiana cuticle as bio-membrane in low-temperature electrolyzer and fuel cells. Appl Sci 9:4461

Wang X, Wei Y, Zhou H, Liu Q, Zhu L (2021) Synthesis of graphene nanosheets by the electrical explosion of graphite powder confined in a tube. Ceram Int 47(15):21934–21942. https://doi.org/10.1016/j.ceramint.2021.04.211

Lawrence A, Thollander P, Andrei M, Karlsson M (2019) Specific energy consumption/use (SEC) in energy management for improving energy efficiency in industry: meaning, usage and differences. Energies 12:247. https://doi.org/10.3390/en12020247

Bian B, Shi L, Katuri KP, Xu J, Wang P, Saikaly PE (2020) Efficient solar-to-acetate conversion from CO2 through microbial electrosynthesis coupled with stable photoanode. Appl Energy 278:115684. https://doi.org/10.1016/j.apenergy.2020.115684

Author information

Authors and Affiliations

Contributions

Andrei V. Kupriashov: conceptualization, methodology, experimental work, investigation, and writing the original draft. Ivan Y. Shestakov: resources, advisory, experimental work, review, editing, and supervision.

Corresponding author

Ethics declarations

Ethical approval

All authors confirm that they follow all ethical guidelines.

Consent to participate

The authors declare that they consent to participate in this paper.

Consent for publication

The authors declare that they consent to publish this paper and agree with the publication.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kupriashov, A.V., Shestakov, I.Y. Influence of electrode arrangement method on specific energy consumption and productivity in electrosynthesis of fine graphite powder. Int J Adv Manuf Technol 119, 7615–7628 (2022). https://doi.org/10.1007/s00170-021-08500-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08500-6