Abstract

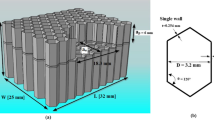

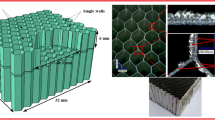

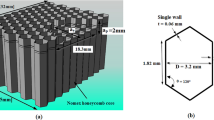

The milling of aluminum honeycomb structures represents today an important scientific and technical research topic for many industrial applications: aerospace, aeronautic, automotive, and naval. The difficulties encountered when milling this type of materials are linked to the small thickness of the walls constituting the honeycomb cells and the ductility of the material structure. The milling of cellular composite structures requires specific and rigorous tools. In the present work, a 3D numerical modeling of the milling process of aluminum honeycombs has been developed using Abaqus Explicit software. The effect of milling parameters, such as the spindle speed, the tilt angle, and the depth of cut, has been particularly investigated in terms of cutting forces, surface integrity, and chip morphology. To properly analyze and optimize the cutting process, experimental validation was done through milling tests with different cutting conditions. The comparison between numerical simulations and experimental tests shows that the three-dimensional model correctly reproduces the milling of this type of structure.

Similar content being viewed by others

References

Cognard P (2003) Collage des composites. Ed. Techniques Ingénieur

Reyne M (1998) Les composites dans les sports et les loisirs. Ed. Techniques Ingénieur

Dessarthe A (1992) Assemblage des matériaux composites, structures sandwichs et matiéres plastiques

Jansons J, Kulakov V, Aniskevich A, Structural LA (2012) Composites− from aerospace to civil engineering applications. Innovations and Technologies News 4(17):3–12

Dessarthe A (1999) Usinage des composites à matrice polymère. Tech. l’Ingénieur

Geng D, Zhang D, Xu Y, He F, Liu D, Duan Z (2015) Rotary ultrasonic elliptical machining for side milling of CFRP: tool performance and surface integrity. Ultrasonics 59:128–137

Teti R (2002) Machining of composite materials. CIRP Ann 51(2):611–634

Zhao H, Elnasri I, Abdennadher S (2005) An experimental study on the behaviour under impact loading of metallic cellular materials. Int J Mech Sci 47(4–5):757–774

Chandler HE (1989) Machining of metal-matrix composites and honeycomb structures. Asm handbook 16:893–901

Qiu K, Ming W, Shen L, An Q, Chen M (2017) Study on the cutting force in machining of aluminum honeycomb core material. Compos Struct 164:58–67

Gao Y, Ko JH, Lee HP (2018) 3D coupled Eulerian-Lagrangian finite element analysis of end milling. Int J Adv Manuf Technol 98(1):849–857

Daoud M, Chatelain JF, Bouzid A (2015) Effect of rake angle on Johnson-Cook material constants and their impact on cutting process parameters of Al2024-T3 alloy machining simulation. Int J Adv Manuf Technol 81(9):1987–1997

Kang P, Youn SK, Lim JH (2013) Modification of the critical projectile diameter of honeycomb sandwich panel considering the channeling effect in hypervelocity impact. Aerosp Sci Technol 29(1):413–425

Huang W, Zhang W, Li D, Ye N, Xie W, Ren P (2016) Dynamic failure of honeycomb-core sandwich structures subjected to underwater impulsive loads. European Journal of Mechanics-A/Solids 60:39–51

Aydin M, Köklü U (2017) Identification and modeling of cutting forces in ball-end milling based on two different finite element models with arbitrary Lagrangian Eulerian technique. Int J Adv Manuf Technol 92:1465–1480

Aydin M, Köklü U (2020) Analysis of flat-end milling forces considering chip formation process in high-speed cutting of Ti6Al4V titanium alloy. Simul Model Pract Theory 100:102–139

Régnier T, Fromentin G, Outeiro J, Marcon B, d'Acunto A, Crolet A (2016) Etude de la formation des bavures en coupe orthogonale à l’outil carbure dans un alliage d’Aluminium – Silicium

Boussaha A (2007) Etude expérimentale des paramètres influants le serti des boites métalliques: Cas de l'unité BENPACK–Batna. Dissertation, Université de Batna 2

Tiabi A (2010) Formation des bavures d'usinage et finition de pièces. Dissertation, École de technologie supérieure

Niknam SA (2013) Burrs understanding, modeling and optimization during slot milling of aluminium alloys Dissertation, École de technologie supérieure

Crupi V, Epasto G, Guglielmino E, Mozafari H, Najafian S (2014) Computed tomography-based reconstruction and finite element modelling of honeycomb sandwiches under low-velocity impacts. J Sandw Struct Mater 16(4):377–397

Johnson GR, Cook WH (1985) Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng Fract Mech 21(1):31–48

Atlati S (2012) Développement d’une nouvelle approche hybride pour la modélisation des échanges thermiques à l’interface outil copeau: application à l’usinage de l’alliage d’aluminium aéronautique AA 2024-T351. Dissertation, Université de Lorraine, France

Jenarthanan MP, Jeyapaul R (2013) Optimisation of machining parameters on milling of GFRP composites by desirability function analysis using Taguchi method. Int J Eng Sci Technol 5(4):22–36

Zarrouk T, Salhi JE, Atlati S, Nouari M, Salhi M, Salhi N (2021) Modeling and numerical simulation of the chip formation process when machining Nomex. Environ Sci Pollut Res 1–8

Jaafar M, Atlati S, Makich H, Julliere B (2017) A 3D FE modeling of machining process of Nomex® honeycomb core: influence of the cell structure behaviour and specific tool geometry. Procedia Cirp 58:505–510

Jaafar M (2018) Étude expérimentale et simulation numérique de l’usinage des matériaux en nids d’abeilles : application au fraisage des structures Nomex® et Aluminium. Dissertation, Université de Lorraine, France

Zarrouk T, Salhi JE, Atlati S, Nouari M, Salhi M, Salhi N (2021) Study on the behavior law when milling the material of the Nomex honeycomb core. Materials Today: Proceedings 45(8):7477–7485

Sahare SB, Untawale SP, Chaudhari SS, Shrivastav RL, Kamble PD (2017) Experimental investigation of end milling operation on Al2024. Mater Today Proc 4(2):1357–1365

Moshat S, Datta S, Bandyopadhyay A, Pal P (2010) Optimization of CNC end milling process parameters using PCA-based Taguchi method. Int J Eng Sci Technol 2(1):95–102

Wang DH, Ramulu M, Arola D (1995) Orthogonal cutting mechanisms of graphite/epoxy composite. Int J Mach Tools Manuf 35(12):1623–1638

Zarrouk T, Salhi JE, Nouari M, Salhi M, Atlati S, Salhi N, Makich H (2021) Analysis of friction and cutting parameters when milling honeycomb composite structures. Adv Mech Eng 13(7):16878140211034840

Turki Y, Habak M, Velasco R, Vantomme P, Aboura Z (2011) Evaluation expérimentale du comportement d'un composite carbone/époxy en usinage. In Congrès français de mécanique. AFM, Maison de la Mécanique, 39/41 rue Louis Blanc, 92400 Courbevoie, France (FR)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zarrouk, T., Nouari, M., Salhi, JE. et al. Optimization of the milling process for aluminum honeycomb structures. Int J Adv Manuf Technol 119, 4733–4744 (2022). https://doi.org/10.1007/s00170-021-08495-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08495-0