Abstract

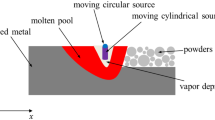

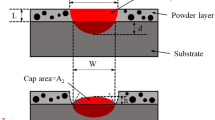

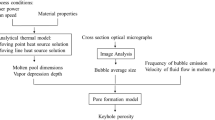

Molten pool geometric characteristics are important factors related to process-induced defects in laser powder bed fusion (LPBF) metal additive manufacturing. Efficient models for rapid predictions of molten pool dimensions will facilitate the study of defects formation in LPBF. In this study, an analytical modeling strategy was developed to predict the molten pool dimensions and vapor depression depth in keyhole melting mode of LPBF. A combined temperature prediction model with closed-form solution was employed to predict the temperature distribution in the part with given process conditions and thermal properties of material. This model consists of a moving point heat source on the top surface of the part and a moving line heat source penetrating into the part. The moving point heat source was used to consider the thermal effects of plasma at the keyhole mouth. The moving line heat source with finite length was employed to consider the laser power absorption by the keyhole walls. The width, depth of molten pool, and vapor depression depth (also called keyhole depth) were determined by comparing the temperature distribution with the melting temperature and boiling point of the material, respectively. To verify the proposed model, the calculated molten pool dimensions under different process conditions were compared with experimental data of Ti6Al4V. The predictions show good agreement with experimental results. The sensitivity analyses of molten pool depth to process conditions were conducted. The computational cost of the proposed model is low because no finite element–based numerical computations are included in this model. The proposed method can provide significant guidance to the optimization of process conditions to avoid the defects related with molten pool size.

source length with normalized enthalpy

Similar content being viewed by others

References

Cunningham R, Zhao C, Parab N, Kantzos C, Pauza J, Fezzaa K, Sun T, Rollett AD (2019) Keyhole threshold and morphology in laser melting revealed by ultrahigh-speed x-ray imaging. Science 363(6429):849–852. https://doi.org/10.1126/science.aav4687

Vastola G, Pei QX, Zhang YW (2018) Predictive model for porosity in powder-bed fusion additive manufacturing at high beam energy regime. Addit Manuf 22:817–822. https://doi.org/10.1016/j.addma.2018.05.042

Wang D, Liu Y, Yang Y, Xiao D (2016) Theoretical and experimental study on surface roughness of 316L stainless steel metal parts obtained through selective laser melting. Rapid Prototyp J. https://doi.org/10.1108/RPJ-06-2015-0078

Wang W, Ning J, Liang SY (2021) Prediction of lack-of-fusion porosity in laser powder-bed fusion considering boundary conditions and sensitivity to laser power absorption. Int J Adv Manuf Technol 112(1):61–70. https://doi.org/10.1007/s00170-020-06224-7

Yadroitsev I, Gusarov A, Yadroitsava I, Smurov I (2010) Single track formation in selective laser melting of metal powders. J Mater Proc Technol 210(12):1624–1631. https://doi.org/10.1016/j.jmatprotec.2010.05.010

Bayat M, Thanki A, Mohanty S, Witvrouw A, Yang S, Thorborg J, Tiedje NS, Hattel JH (2019) Keyhole-induced porosities in Laser-based Powder Bed Fusion (L-PBF) of Ti6Al4V: high-fidelity modelling and experimental validation. Addit Manuf 30:100835. https://doi.org/10.1016/j.addma.2019.100835

Patel S, Vlasea M (2020) Melting modes in laser powder bed fusion. Materialia 9:100591. https://doi.org/10.1016/j.mtla.2020.100591

Bertoli US, Wolfer AJ, Matthews MJ, Delplanque JP, Schoenung JM (2017) On the limitations of volumetric energy density as a design parameter for selective laser melting. Mater Des 113:331–340. https://doi.org/10.1016/j.matdes.2016.10.037

Johnson L, Mahmoudi M, Zhang B, Seede R, Huang X, Maier JT, Maier HJ, Karaman I, Elwany A, Arróyave R (2019) Assessing printability maps in additive manufacturing of metal alloys. Acta Mater 176:199–210. https://doi.org/10.1016/j.actamat.2019.07.005

Ning J, Wang W, Ning X, Sievers DE, Garmestani H, Liang SY (2020) Analytical thermal modeling of powder bed metal additive manufacturing considering powder size variation and packing. Materials 13(8):1988. https://doi.org/10.3390/ma13081988

Tang M, Pistorius PC, Beuth JL (2017) Prediction of lack-of-fusion porosity for powder bed fusion. Addit Manuf 14:39–48. https://doi.org/10.1016/j.addma.2016.12.001

Promoppatum P, Yao SC, Pistorius PC, Rollett AD (2017) A comprehensive comparison of the analytical and numerical prediction of the thermal history and solidification microstructure of Inconel 718 products made by laser powder-bed fusion. Engineering 3(5):685–694. https://doi.org/10.1016/J.ENG.2017.05.023

Wang W, Ning J, Liang SY (2021) In-situ distortion prediction in metal additive manufacturing considering boundary conditions. Int J Precis Eng Manuf 22(5):909–917. https://doi.org/10.1007/s12541-021-00496-z

Thampy V, Fong AY, Calta NP, Wang J, Martin AA, Depond PJ, Kiss AM, Guss G, Xing Q, Ott RT, van Buuren A (2020) Subsurface cooling rates and microstructural response during laser based metal additive manufacturing. Sci rep 10(1):1–9. https://doi.org/10.1038/s41598-020-58598-z

Fotovvati B, Wayne SF, Lewis G, Asadi E (2018) A review on melt-pool characteristics in laser welding of metals. Adv Mater Sci Eng 2018. https://doi.org/10.1155/2018/4920718

Tsai MT, Chen YW, Chao CY, Jang JS, Tsai CC, Su YL, Kuo CN (2020) Heat-treatment effects on mechanical properties and microstructure evolution of Ti-6Al-4V alloy fabricated by laser powder bed fusion. J Alloys Compd 816:152615. https://doi.org/10.1016/j.jallcom.2019.152615

Obidigbo C, Tatman EP, Gockel J (2019) Processing parameter and transient effects on melt pool geometry in additive manufacturing of Invar 36. Int J Adv Manuf Technol 104(5):3139–3146. https://doi.org/10.1007/s00170-019-04229-5

Martin AA, Calta NP, Khairallah SA, Wang J, Depond PJ, Fong AY, Thampy V, Guss GM, Kiss AM, Stone KH, Tassone CJ (2019) Dynamics of pore formation during laser powder bed fusion additive manufacturing. Nat Commun 10(1):1. https://doi.org/10.1038/s41467-019-10009-2

Heigel JC, Lane BM (2018) Measurement of the melt pool length during single scan tracks in a commercial laser powder bed fusion process. J Manuf Sci Eng 140(5). https://doi.org/10.1115/1.4037571

Gould B, Wolff S, Parab N, Zhao C, Lorenzo-Martin MC, Fezzaa K, Greco A, Sun T (2021) In situ analysis of laser powder bed fusion using simultaneous high-speed infrared and x-ray imaging. JOM 73(1):201–211. https://doi.org/10.1007/s11837-020-04291-5

Balbaa M, Mekhiel S, Elbestawi M, McIsaac J (2020) On selective laser melting of Inconel 718: densification, surface roughness, and residual stresses. Mater Des 193:108818. https://doi.org/10.1016/j.matdes.2020.108818

Cheng B, Loeber L, Willeck H, Hartel U, Tuffile C (2019) Computational investigation of melt pool process dynamics and pore formation in laser powder bed fusion. J Mater Eng Perform 28(11):6565–6578. https://doi.org/10.1007/s11665-019-04435-y

Shrestha S, Kevin Chou Y (2019) A numerical study on the keyhole formation during laser powder bed fusion process. J Manuf Sci Eng 141(10). https://doi.org/10.1115/1.4044100

Philo AM, Mehraban S, Holmes M, Sillars S, Sutcliffe CJ, Sienz J, Brown SG, Lavery NP (2019) A pragmatic continuum level model for the prediction of the onset of keyholing in laser powder bed fusion. The International J Adv Manuf Technol 101(1):697–714. https://doi.org/10.1007/s00170-018-2770-7

Khairallah SA, Anderson A (2014) Mesoscopic simulation model of selective laser melting of stainless steel powder. J Mater Proc Technol 214(11):2627–2636. https://doi.org/10.1016/j.jmatprotec.2014.06.001

Zhang Z, Huang Y, Kasinathan AR, Shahabad SI, Ali U, Mahmoodkhani Y, Toyserkani E (2019) 3-Dimensional heat transfer modeling for laser powder-bed fusion additive manufacturing with volumetric heat sources based on varied thermal conductivity and absorptivity. Opt Laser Technol 109:297–312. https://doi.org/10.1016/j.optlastec.2018.08.012

Karayagiz K, Elwany A, Tapia G, Franco B, Johnson L, Ma J, Karaman I, Arróyave R (2019) Numerical and experimental analysis of heat distribution in the laser powder bed fusion of Ti-6Al-4V. IISE Transactions 51(2):136–152. https://doi.org/10.1080/24725854.2018.1461964

Ning J, Mirkoohi E, Dong Y, Sievers DE, Garmestani H, Liang SY (2019) Analytical modeling of 3D temperature distribution in selective laser melting of Ti-6Al-4V considering part boundary conditions. J Manuf Proc 44:319–326. https://doi.org/10.1016/j.jmapro.2019.06.013

Mirkoohi E, Seivers DE, Garmestani H, Liang SY (2019) Heat source modeling in selective laser melting. Materials 12(13):2052. https://doi.org/10.3390/ma12132052

Van Elsen M, Baelmans M, Mercelis P, Kruth JP (2007) Solutions for modelling moving heat sources in a semi-infinite medium and applications to laser material processing. International J Heat Mass Trans 50(23–24):4872–4882. https://doi.org/10.1016/j.ijheatmasstransfer.2007.02.044

Carslaw HS, Jaeger JC (1959) Conduction of heat in solids. Clarendon Press

Panas AJ (2014) Moving heat sources. Encyclopedia Therm Stresses 3215–27. https://doi.org/10.1007/978-94-007-2739-7_397

King WE, Barth HD, Castillo VM, Gallegos GF, Gibbs JW, Hahn DE, Kamath C, Rubenchik AM (2014) Observation of keyhole-mode laser melting in laser powder-bed fusion additive manufacturing. J Mater Proc Technol 214(12):2915–2925. https://doi.org/10.1016/j.jmatprotec.2014.06.005

Molina-Giraldo N, Blum P, Zhu K, Bayer P, Fang Z (2011) A moving finite line source model to simulate borehole heat exchangers with groundwater advection. International J Therm Sci 50(12):2506–2513. https://doi.org/10.1016/j.ijthermalsci.2011.06.012

Park HS, Ansari MJ (2018) Numerical investigation and an effective predicting system on the Selective Laser Melting (SLM) process with Ti6Al4V alloy. In IOP Conf Ser: Mater Sci Eng 400(4):042046. IOP Publishing. https://doi.org/10.1088/1757-899X/400/4/042046

Rai R, Elmer JW, Palmer TA, DebRoy T (2007) Heat transfer and fluid flow during keyhole mode laser welding of tantalum, Ti–6Al–4V, 304L stainless steel and vanadium. J Phys D: Appl Phys 40(18):5753. https://doi.org/10.1088/0022-3727/40/18/037

Ye J, Khairallah SA, Rubenchik AM, Crumb MF, Guss G, Belak J, Matthews MJ (2019) Energy coupling mechanisms and scaling behavior associated with laser powder bed fusion additive manufacturing. Adv Eng Mater 21(7):1900185. https://doi.org/10.1002/adem.201900185

Trapp J, Rubenchik AM, Guss G, Matthews MJ (2017) In situ absorptivity measurements of metallic powders during laser powder-bed fusion additive manufacturing. Appl Mater Today 9:341–349. https://doi.org/10.1016/j.apmt.2017.08.006

Wang YM, Kamath C, Voisin T, Li Z (2018) A processing diagram for high-density Ti-6Al-4V by selective laser melting. Rapid Prototyp J. https://doi.org/10.1108/RPJ-11-2017-0228

Gong H, Rafi K, Gu H, Starr T, Stucker B (2014) Analysis of defect generation in Ti–6Al–4V parts made using powder bed fusion additive manufacturing processes. Addit Manuf 1:87–98. https://doi.org/10.1016/j.addma.2014.08.002

Yang J, Han J, Yu H, Yin J, Gao M, Wang Z, Zeng X (2016) Role of molten pool mode on formability, microstructure and mechanical properties of selective laser melted Ti-6Al-4V alloy. Mater Des 110:558–570. https://doi.org/10.1016/j.matdes.2016.08.036

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, W., Garmestani, H. & Liang, S.Y. Prediction of molten pool size and vapor depression depth in keyhole melting mode of laser powder bed fusion. Int J Adv Manuf Technol 119, 6215–6223 (2022). https://doi.org/10.1007/s00170-021-08295-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08295-6