Abstract

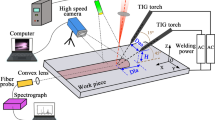

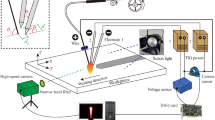

Based on the dynamic behavior of laser keyhole, the time characteristics of coupling discharge of heat source in pulsed laser–induced twin TIG welding (LITTW) are studied. The behaviors of arc plasma and laser keyhole were directly observed by high-speed camera and auxiliary illumination source. The physical characteristics of arc plasma were analyzed by spectrometer and arc quality analyzer. A physical model is established to reveal the regulation mechanism of time characteristics of coupling discharge. It is found that after laser pulse action, the coupling discharge between keyhole plasma and double-arc plasma does not end immediately, and its time depends on the existence time of keyhole. During hybrid welding, when the combined force of arc pressure and Marangoni force can overcome the gravity, the liquid metal is forced out of the keyhole and the keyhole remains open. Improving the electron density of arc plasma and arc voltage and reducing the diameter of arc conductive channel by selecting appropriate parameters is the key to prolong the existence time of keyhole, which is beneficial to improve the welding penetration. The coupling enhancement of double-arc electromagnetic field in LITTW can effectively suppress keyhole backfill and increase the duty ratio of coupling discharge. When the total current intensity is 200 A, compared with laser-induced single TIG welding (LISTW), the existence time of keyhole in LITTW increases by 77%, the duty ratio of coupling discharge increases by 12%, and the weld penetration increases by 29.2%.

Similar content being viewed by others

Data availability

All the data have been presented in the manuscript.

Code availability

Not applicable.

References

Steen W (1980) Arc augmented laser processing of materials. J Appl Phys 51(11):5636–5641

Jiang F, Wang S, Xu B, Cheng W, Ma X, Chen S (2021) Local energy adjustment mechanism in a novel laser-enhanced plasma arc heat source. Int J Therm Sci 168

Ragavendran M, Chandrasekhar N, Ravikumar R, Saxena R, Vasudevan M, Bhaduri AK (2017) Optimization of hybrid laser-TIG welding of 316LN steel using response surface methodology (RSM). Opt Laser Eng 94:27–36

Wieschemann A, Keller H, Dilthey U (2003) Hybrid-welding and the HyDra MAG+Laser processes in shipbuilding. Weld Int 17(10):761–766

Qin G, Meng X, Fu B (2015) High speed tandem gas tungsten arc welding process of thin stainless steel plate. J Mater Process Tech 220:58–64

Scalet Rossini LF, Valenzuela Reyes RA, Spinelli JE (2019) Double-wire tandem GMAW welding process of HSLA50 steel. J Manuf Process 45:227–233

Gu X, Li H, Jiang X, Sheng H, Wan X (2016) Effect of laser on droplet transfer and welding process stability in hybrid laser + double arc welding. Int J Adv Manuf Tech 89(9–12):2981–2991

Wei HL, Li H, Yang LJ, Gao Y, Ding XP (2015) Arc characteristics and metal transfer process of hybrid laser double GMA welding. Int J Adv Manuf Tech 77:1019–1028

Hu L, Huang J, Liu C, Liu X, Hou D, Xu C, Zhao Y (2018) Effects of coupling between the laser plasma and two arcs on metal transfer in CO2 laser double-wire MIG hybrid welding. Opt Laser Technol 105:152–161

Gu X, Li H, Yang L, Gao Y (2013) Coupling mechanism of laser and arcs of laser-twin-arc hybrid welding and its effect on welding process. Opt Laser Technol 48:246–253

Liu L, Hao X (2008) Study of the effect of low-power pulse laser on arc plasma and magnesium alloy target in hybrid welding by spectral diagnosis technique. J Phys D Appl Phys 41(20)

Xu GX, Wu CS, Qin GL, Wang XY, Lin SY (2011) Adaptive volumetric heat source models for laser beam and laser-pulsed GMAW hybrid welding processes. Int J Adv Manuf Tech 57:245–255

Hu B, Ouden G (2005) Laser induced stabilisation of the welding arc. Sci Technol Weld J 10:76–81

Zhan XH, Chen JC, Liu JJ, Wei YH, Zhou J, Meng Y (2016) Microstructure and magnesium burning loss behavior of AA6061 electron beam welding joints. Mater Design 99:449–458

Liu L, Chen M (2011) Interactions between laser and arc plasma during laser–arc hybrid welding of magnesium alloy. Opt Laser Eng 49(9–10):1224–1231

Sabbaghzadeh J, Dadras S, Torkamany MJ (2007) Comparison of pulsed Nd : YAG laser welding qualitative features with plasma plume thermal characteristics. J Phys D Appl Phys 40(4):1047–1051

(2019) National Institute of Standards and Technology database. https://www.nist.gov/pml/atomic-spectra-database Accessed 25 December 2019

Griem H (1974) Spectral line broadening by plasma. Academic Press, New York

Liu L, Xu X, Zhu Y (2020) Study on synchronous induction of arc plasma by laser in laser-double TIG hybrid welding. Opt Laser Eng 133

Liu L, Chen M, Li C (2013) Effect of electric arc on laser keyhole behavior based on direct observation during low power pulsed laser–arc hybrid welding process. Opt Laser Eng 51(10):1153–1160

Leng X, Zhang G, Wu L (2006) The characteristic of twin-electrode TIG coupling arc pressure. J Phys D Appl Phys 39(6):1120–1126

AnTeng H, ChangGu C (1985) Welding arc phenomenon. Machinery Industry Press

Wang X, Luo Y, Fan D (2019) Investigation of heat transfer and fluid flow in high current GTA welding by a unified model. Int J Therm Sci 142:20–29

Abderrazak K, Kriaa W, Ben Salem W, Mhiri H, Lepalec G, Autric M (2009) Numerical and experimental studies of molten pool formation during an interaction of a pulse laser (Nd:YAG) with a magnesium alloy. Opt Laser Technol 41(4):470–480

Ai Y, Liu X, Huang Y, Yu L (2020) Numerical analysis of the influence of molten pool instability on the weld formation during the high speed fiber laser welding. Int J Heat Mass Transf 160

Funding

This work was supported by the National Key R&D Program of China (2018YFB1107902) organization name: Ministry of Science and Technology of the People’s Republic of China.

Author information

Authors and Affiliations

Contributions

Xinkun Xu: roles/writing—original draft; methodology; formal analysis.

Huanyu Yang: data curation; supervision; validation.

Liming Liu: conceptualization; funding acquisition; writing—review and editing.

Corresponding author

Ethics declarations

Ethics approval

The paper follows the guidelines of the Committee on Publication Ethics (COPE).

Consent to participate

The authors declare that they all consent to participate this research.

Consent for publication

The authors declare that they all consent to publish the manuscript.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xu, X., Yang, H. & Liu, L. Study on time characteristics of coupling discharge in pulsed laser–induced twin TIG welding. Int J Adv Manuf Technol 119, 389–402 (2022). https://doi.org/10.1007/s00170-021-08255-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08255-0