Abstract

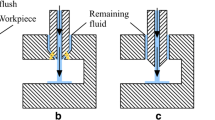

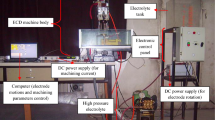

The micro-hole array machined by micro-electrical discharge machining (micro-EDM) has been widely used in aerospace, electronic communication, and other industrial fields. However, due to the unavoidable electrode wear and the unstable discharge state during the electrode breakthrough, the electrode breakthrough detection is usually inaccurate, and the servo tracking performance is also poor, which has adverse effect on the machining efficiency and quality of micro-hole array. In the present study, a three-dimensional flow field model was established, and the gap flow field before and after electrode breakthrough based on the model was analyzed. Simulation results showed that the flow field pattern of dielectric was changed and the flow velocities in bottom gap increased in general after electrode broke through the workpiece, which enabled to analyze the influence of the variation in flushing mechanism of debris on the discharge state in breakthrough stage to some extent. A scheme was proposed for online detecting the breakthrough by monitoring the variations of the gap voltage and the electrode displacement, and the verification experiment was carried out. The proposed scheme has been shown to guarantee the electrode breakthrough, while in the same time controlling the distance of electrode feeding past the micro-hole outlet not exceeding 25 μm. In addition, a segmented servo strategy was proposed to ensure the machining performance of micro-hole array, and it was experimentally tested. This strategy could reduce the average machining time of micro-hole array by about 36% and ensure the machining quality of micro-hole outlet.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Mastud SA, Garg M, Singh R (2012) Recent developments in the reverse micro-electrical discharge machining in the fabrication of arrayed micro-features. J Mech Eng Sci 226:367–383

Ming PM, Li YJ, Wang YL (2012) Fabrication of micro-precision sieves with high open area percentage using micro-electroforming technology. Adv Mater Res 426:64–68

Shen SC, Pan CT, Wang YR, Chang CC (2006) Fabrication of integrated nozzle plates for inkjet print head using microinjection process. Sensors Actuators A Phys 127:241–247

Hourmand M, Sarhan AAD, Sayuti M (2017) Micro-electrode fabrication processes for micro-EDM drilling and milling: a state-of-the-art review. Int J Adv Manuf Technol 91:1023–1056

Takahata K, Guckel H, Shibaike N (2000) High-aspect-ratio WC-Co microstructure produced by the combination of LIGA and micro-EDM. Microsyst Technol 6:175–178

Xu J, Guo B, Shan DB, Wang CJ, Li J, Liu YW, Qu DS (2012) Development of a micro-forming system for micro-punching process of micro-hole arrays in brass foil. J Mater Process Technol 212:2238–2246

Nam JS, Lee PH, Lee SW (2011) Experimental characterization of micro-drilling process using nanofluid minimum quantity lubrication. Int J Mach Tool Manu 51:649–652

Meng LN, Wang AH, Wu Y, Wang X, Xia HB, Wang YN (2015) Blind micro-hole array Ti6Al4V templates for carrying biomaterials fabricated by fiber laser drilling. J Mater Process Technol 222:335–343

Wang ZP, Feng GY, Wang ST, Li G, Dai SY, Zhou SH (2017) Improving the quality of femtosecond laser processing micro-hole array by coated with aluminum film on fused silica sheet. Optik 128:178–184

Joo BY, Rhim SH, Soo KO (2005) Micro-hole fabrication by mechanical punching process. J Mater Process Technol 170:593–601

Zou ZX, Guo ZN, Huang QM, Yue TM, Liu JW, Chen XL (2021) Precision EDM of micron-scale diameter hole array using in-process wire electro-discharge grinding high-aspect-ratio microelectrodes. Micromachines 12:17

Peng ZL, Feng TM, Wei ZL, Zhang Y, Li YN (2019) Directly writing patterning of conductive material by high voltage induced weak electric arc machining (HV-μEAM). Coatings 9:9

Wang X, Liu Z, Xue R, Tian Z, Huang Y (2014) Research on the influence of dielectric characteristics on the EDM of titanium alloy. Int J Adv Manuf Technol 72:979–987

Aggarwal V, Khangura SS, Garg RK (2015) Parametric modeling and optimization for wire electrical discharge machining of Inconel 718 using response surface methodology. Int J Adv Manuf Technol 79:31–47

Ji RJ, Liu YH, Diao RQ, Zhang YZ, Wang F, Cai BP, Xu CC (2014) Experimental research on electrical discharge machining characteristics of engineering ceramics with different electrical resistivities. Int J Adv Manuf Technol 75:1743–1750

Wu XL, Liu YH, Zhang XX, Dong H, Zheng C, Zhang F, Sun Q, Jin H, Ji RJ (2020) Sustainable and high-efficiency green electrical discharge machining milling method. J Clean Prod 274:123040

Feng YR, Guo YF, Ling ZB, Zhang XY (2019) Micro-holes EDM of superalloy Inconel 718 based on a magnetic suspension spindle system. Int J Adv Manuf Technol 101:2015–2026

Ferraris E, Castiglioni V, Ceyssens F, Annoni M, Lauwers B, Reynaerts D (2013) EDM drilling of ultra-high aspect ratio micro holes with insulated tools. CIRP Ann Manuf Technol 62:191–194

Natsu W, Maeda H (2018) Realization of high-speed micro EDM for high-aspect-ratio micro hole with mist nozzle. Procedia CIRP 68:575–577

Leao FN, Pashby IR, Cuttell M, Lord P (2005) Optimisation of EDM fast hole-drilling through evaluation of dielectric and electrode material. 18th Int Congr Mech Eng

Xia WW, Zhang YO, Chen M, Zhao WS (2020) Study on gap phenomena before and after the breakout event of fast electrical discharge machining drilling. J Manuf Sci Eng 142:041004

Gao Q (2018) Impact of electrode length on EDM inclined hole drilling process. Int J Adv Manuf Technol 94:1171–1175

Koshy P, Boroumand M, Ziada Y (2010) Breakout detection in fast hole electrical discharge machining. Int J Mach Tools Manuf 50:922–925

Li ZK, Bai JC, Cao Y, Wang YQ, Zhu GZ (2019) Fabrication of microelectrode with large aspect ratio and precision machining of micro-hole array by micro-EDM. J Mater Process Technol 268:70–79

Nirala CK, Saha P (2017) Precise μEDM-drilling using real-time indirect tool wear compensation. J Mater Process Technol 240:176–189

Pham DT, Ivanov A, Bigot S, Popov K, Dimov S (2007) An investigation of tube and rod electrode wear in micro EDM drilling. Int J Mach Tools Manuf 33:103–109

Xia WW, Li ZL, Zhang YO, Zhao WS (2020) Breakout detection for fast EDM drilling by classification of machining state graphs. Int J Mach Tools Manuf 106:1645–1656

Smith C, Koshy P (2013) Applications of acoustic mapping in electrical discharge machining. CIRP Ann Manuf Technol 62:171–174

Bellotti M, Qian J, Reynaerts D (2020) Self-tuning breakthrough detection for EDM drilling micro holes. J Manuf Process 57:630–640

Bellotti M, Qian J, Reynaerts D (2019) Breakthrough phenomena in drilling micro holes by EDM. Int J Mach Tools Manuf 146: 103436

Liu H, Bai JC, Cao Y, Zhu GZ, Hou SJ (2020) Micro-electrode wear and compensation to ensure the dimensional consistency accuracy of micro-hole array in micro-EDM drilling. Int J Mach Tools Manuf 111:2653–2665

Ho KH, Newman ST (2003) State of the art electrical discharge machining (EDM). Int J Mach Tools Manuf 43:1287–1300

Kunieda M, Lauwers B, Rajurkar KP, Schumacher BM (2005) Advancing EDM through fundamental insight into the process. CIRP Ann Manuf Technol 54:64–87

Kliuev M, Boccadoro M, Perez R, DalBó W, Stirnimann J, Kuster F, Wegener K (2016) EDM drilling and shaping of cooling holes in Inconel 718 turbine blades. Procedia CIRP 42:322–327

Dauw DF, Snoeys R, Dekeyser W (1983) Advanced pulse discriminating system for EDM process analysis and control. CIRP Ann Manuf Technol 32:541–549

Funding

This project is supported by the National Natural Science Foundation of China (No. 51575137), the Key Project of Natural Science Foundation of Heilongjiang Province of China (No. ZD2019E005), and the National Natural Science Foundation of China (No. 51975156).

Author information

Authors and Affiliations

Contributions

Huan Liu: conceptualization, methodology, and writing—original draft preparation. Jicheng Bai: supervision, project administration, and funding acquisition. Bo Zhang: investigation, data curation, and visualization. Yan Cao: writing—review and editing. Shaojie Hou: investigation and validation. Zimu Zhou: investigation and validation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, H., Bai, J., Zhang, B. et al. Breakthrough detection and servo control for micro‑hole array EDM drilling. Int J Adv Manuf Technol 119, 615–629 (2022). https://doi.org/10.1007/s00170-021-08205-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08205-w