Abstract

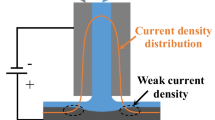

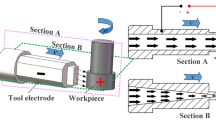

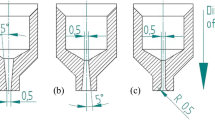

Electrochemical jet machining of titanium alloy is presented in this paper, where the effects of major process parameters including pulse frequency and duty cycle on cavity dimensions and material removal rate were investigated and analyzed through experiments. A parametric model was also developed in this study for predicting the material removal rate and cavity profile. Although the use of high open voltage together with high pulse frequency and large duty cycle tended to produce a wide and deep cavity, a non-circular cavity with pitting holes formed around the cavity’s edge was usually obtained as a result. The open voltage of 25 V and duty cycle of 50% were suggested for preventing the formation of surface pitting and keeping the fabricated cavity to be a circular shape. In addition, the parametric model developed in this study was able to predict the material removal rate and cavity depth with a well agreement compared to the experiments. Regarding the experimental findings and model, the critical current density and average specific energy required for removing the titanium alloy by the electrochemical jet machining process were 6.2 A/cm2 and 4000 J/mm3, respectively.

Similar content being viewed by others

Availability of data and material

Not applicable.

Code availability

Not applicable.

References

Saxena KK, Qian J, Reynaerts D (2018) A review on process capabilities of electrochemical micromachining and its hybrid variants. Int J Mach Tools Manuf 127:28–56. https://doi.org/10.1016/j.ijmachtools.2018.01.004

Kendall T, Bartolo P, Gillen D, Diver C (2019) A review of physical experimental research in jet electrochemical machining. Int J Adv Manuf Technol 105(1):651–667. https://doi.org/10.1007/s00170-019-04099-x

Zeng Y, Fang X, Zhang Y, Qu N (2014) Electrochemical drilling of deep small holes in titanium alloys with pulsating electrolyte flow. Adv Mech Eng 6:167070. https://doi.org/10.1155/2014/167070

Liu W, Ao S, Li Y, Liu Z, Wang Z, Luo Z, Wang Z, Song R (2017) Jet electrochemical machining of TB6 titanium alloy. Int J Adv Manuf Technol 90(5):2397–2409. https://doi.org/10.1007/s00170-016-9500-9

Mishra K, Dey D, Sarkar BR, Bhattacharyya B (2017) Experimental investigation into electrochemical milling of Ti6Al4V. J Manuf Process 29:113–123. https://doi.org/10.1016/j.jmapro.2017.07.014

Davydov AD, Kabanova TB, Volgin VM (2017) Electrochemical machining of titanium. Rev Russ J Electrochem 53(9):941–965. https://doi.org/10.1134/s102319351709004x

Speidel A, Mitchell-Smith J, Bisterov I, Clare AT (2019) Oscillatory behaviour in the electrochemical jet processing of titanium. J Mater Process Technol 273:116264. https://doi.org/10.1016/j.jmatprotec.2019.116264

Anasane SS, Bhattacharyya B (2016) Experimental investigation on suitability of electrolytes for electrochemical micromachining of titanium. Int J Adv Manuf Technol 86(5):2147–2160. https://doi.org/10.1007/s00170-015-8309-2

Wang X, Qu N, Fang X (2019) Reducing stray corrosion in jet electrochemical milling by adjusting the jet shape. J Mater Process Technol 264:240–248. https://doi.org/10.1016/j.jmatprotec.2018.09.017

Wang GQ, Zhu D, Li HS (2018) Fabrication of semi-circular micro-groove on titanium alloy surface by through-mask electrochemical micromachining. J Mater Process Technol 258:22–28. https://doi.org/10.1016/j.jmatprotec.2018.03.015

Chen XL, Dong BY, Zhang CY, Luo HP, Liu JW, Zhang YJ, Guo ZN (2019) Electrochemical direct-writing machining of micro-channel array. J Mater Process Technol 265:138–149. https://doi.org/10.1016/j.jmatprotec.2018.10.014

Liu W, Ao S, Li Y, Liu Z, Zhang H, Manladan SM, Luo Z, Wang Z (2017) Effect of anodic behavior on electrochemical machining of TB6 titanium alloy. Electrochim Acta 233:190–200. https://doi.org/10.1016/j.electacta.2017.03.025

Mitchell-Smith J, Clare AT (2016) Electrochemical jet machining of titanium: overcoming passivation layers with ultrasonic assistance. Procedia CIRP 42:379–383. https://doi.org/10.1016/j.procir.2016.02.215

Speidel A, Mitchell-Smith J, Walsh DA, Hirsch M, Clare A (2016) Electrolyte jet machining of titanium alloys using novel electrolyte solutions. Procedia CIRP 42:367–372. https://doi.org/10.1016/j.procir.2016.02.200

Chen X, Qu N, Li H, Xu Z (2016) Electrochemical micromachining of micro-dimple arrays using a polydimethylsiloxane (PDMS) mask. J Mater Process Technol 229:102–110. https://doi.org/10.1016/j.jmatprotec.2015.09.008

He H, Qu N, Zeng Y, Fang X, Yao Y (2016) Machining accuracy in pulsed wire electrochemical machining of γ-TiAl alloy. Int J Adv Manuf Technol 86(5):2353–2359. https://doi.org/10.1007/s00170-016-8402-1

Baehre D, Ernst A, Weißhaar K, Natter H, Stolpe M, Busch R (2016) Electrochemical dissolution behavior of titanium and titanium-based alloys in different electrolytes. Procedia CIRP 42:137–142. https://doi.org/10.1016/j.procir.2016.02.208

Xu Z, Chen X, Zhou Z, Qin P, Zhu D (2016) Electrochemical machining of high-temperature titanium alloy Ti60. Procedia CIRP 42:125–130. https://doi.org/10.1016/j.procir.2016.02.206

Smirnov GV, Pronichev ND, Nekhoroshev MV, Bogdanovich VI (2017) Experimental and theoretical study of the hydriding behaviour in the pulse ecm of titanium alloys. IOP Conf Ser Mater Sci Eng 177:012131. https://doi.org/10.1088/1757-899x/177/1/012131

Wang X, Qu N, Fang X, Li H (2016) Electrochemical drilling with constant electrolyte flow. J Mater Process Technol 238:1–7. https://doi.org/10.1016/j.jmatprotec.2016.06.033

Funding

This study received financial support from the Petchra Pra Jom Klao Ph.D. Research Scholarship from King Mongkut’s University of Technology Thonburi, the Natural Science Foundation of Jiangsu Province (Grant no. BK20180875), and Thailand Science Research and Innovation (TSRI) under Fundamental Fund 2022 (Project: Advanced Materials and Manufacturing for Applications in New S-curve Industries).

Author information

Authors and Affiliations

Contributions

Ornsurang Netprasert: methodology, formal analysis, investigation, writing—original draft. Viboon Tangwarodomnukun: conceptualization; methodology; formal analysis; validation; visualization; writing—review and editing; supervision. Hao Zhu: writing—review and editing. Chaiya Dumkum: writing—review and editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Netprasert, O., Tangwarodomnukun, V., Zhu, H. et al. Parametric analysis and modeling of electrochemical jet machining of titanium alloy. Int J Adv Manuf Technol 118, 3725–3736 (2022). https://doi.org/10.1007/s00170-021-08202-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08202-z