Abstract

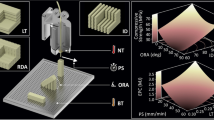

Material extrusion (ME) is an additive manufacturing technology employed for a wide variety of parts and several applications. Along with its benefits, there are drawbacks regarding ME, such as the anisotropy of specimens that provides different values for mechanical properties and residual stresses. There is a need for optimizing the printing parameters since they are linked to the mechanical behavior of printed parts. One way to reach that goal is by carrying out physical experiments that grant accurate results but at a high cost. Another strategy is to simulate the printing process using specialized software. Therefore, it is vital to determine if a simulation approach is robust enough to predict component’s performance. The present study shows the optimization of process parameters to improve the yield strength of printed specimens made of acrylonitrile–butadiene–styrene (ABS). Experimental runs and a numerical simulation based on thermo-mechanical analyses executed in Digimat software are introduced. Taguchi method and analyses of variance (ANOVA) allowed estimating the effects of process parameters and their optimal values to enhance coupon’s yield strength for both approaches. Optimum levels for experimental and simulated results diverge for layer thickness and infill density. The difference between yield stress dictated by physical and simulated values is below 9% for 75% of the experimental runs. Digimat’s simulations gave a good insight into the material extrusion of plastic materials, but when used for the optimization of printing parameters, they provided lower yield stress values than the ones obtained by experimental methods.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are not publicly available as data also form part of an ongoing study but are available from the corresponding author on reasonable request.

References

Alaimo G, Marconi S, Costato L, Auricchio F (2017) Influence of meso-structure and chemical composition on FDM 3D-printed parts. Compos Part B Eng 113:371–380. https://doi.org/10.1016/J.COMPOSITESB.2017.01.019

Conway KM, Pataky GJ (2019) Crazing in additively manufactured acrylonitrile butadiene styrene. Eng Fract Mech. https://doi.org/10.1016/j.engfracmech.2019.02.020

Manyika J, Chui M, Bughin J, et al Disruptive technologies: advances that will transform life, business, and the global economy. In: McKinsey Glob. Inst. https://www.mckinsey.com/~/media/McKinsey/Business Functions/McKinsey Digital/Our Insights/Disruptive technologies/MGI_Disruptive_technologies_Full_report_May2013.pdf. Accessed 16 Dec 2020

52900:2015 A (2015) Standard Terminology for Additive Manufacturing – General Principles – Terminology. ASTM Int. https://www.iso.org/standard/69669.html. Accessed 16 Dec 2020

Rashid A (2018) Additive manufacturing technologies. In: Chatti S, Tolio T (eds) CIRP Encyclopedia of production engineering. Springer, Berlin Heidelberg, Berlin, Heidelberg, pp 1–9

Yao T, Deng Z, Zhang K, Li S (2019) A method to predict the ultimate tensile strength of 3D printing polylactic acid (PLA) materials with different printing orientations. Compos Part B Eng. https://doi.org/10.1016/j.compositesb.2019.01.025

Zhang J, Wang P, Gao RX (2019) Deep learning-based tensile strength prediction in fused deposition modeling. Comput Ind. https://doi.org/10.1016/j.compind.2019.01.011

Wankhede V, Jagetiya D, Joshi A, Chaudhari R (2019) Experimental investigation of FDM process parameters using Taguchi analysis. Mater Today Proc. https://doi.org/10.1016/j.matpr.2019.09.078

Deswal S, Narang R, Chhabra D (2019) Modeling and parametric optimization of FDM 3D printing process using hybrid techniques for enhancing dimensional preciseness. Int J Interact Des Manuf. https://doi.org/10.1007/s12008-019-00536-z

Ding S, Zou B, Wang P, Ding H (2019) Effects of nozzle temperature and building orientation on mechanical properties and microstructure of PEEK and PEI printed by 3D-FDM. Polym Test. https://doi.org/10.1016/j.polymertesting.2019.105948

Hallmann M, Goetz S, Schleich B, Wartzack S (2019) Optimization of build time and support material quantity for the additive manufacturing of non-assembly mechanisms. Procedia CIRP 84:271–276. https://doi.org/10.1016/j.procir.2019.03.197

Tanoto YY, Anggono J, Siahaan IH, Budiman W (2017) The effect of orientation difference in fused deposition modeling of ABS polymer on the processing time, dimension accuracy, and strength. In: AIP Conference Proceedings. https://doi.org/10.1063/1.4968304

Alafaghani A, Qattawi A, Alrawi B, Guzman A (2017) Experimental optimization of fused deposition modelling processing parameters: a design-for-manufacturing approach. procedia manuf. https://doi.org/10.1016/j.promfg.2017.07.079

Huynh HN, Nguyen AT, Ha NL, Ha Thai TT (2017) Application of fuzzy Taguchi method to improve the dimensional accuracy of Fused Deposition Modeling processed product. In: Proceedings - 2017 International Conference on System Science and Engineering, ICSSE 2017. https://doi.org/10.1109/ICSSE.2017.8030847

Mohamed OA, Masood SH, Bhowmik JL (2016) Optimization of fused deposition modeling process parameters for dimensional accuracy using I-optimality criterion. Meas J Int Meas Confed. https://doi.org/10.1016/j.measurement.2015.12.011

Balla VK, Kate KH, Satyavolu J, et al (2019) Additive manufacturing of natural fiber reinforced polymer composites: Processing and prospects. Compos. Part B Eng. https://doi.org/10.1016/j.compositesb.2019.106956

Raut S, Jatti VS, Khedkar NK, Singh TP (2014) Investigation of the effect of built orientation on mechanical properties and total cost of FDM parts. Procedia Mater Sci. https://doi.org/10.1016/j.mspro.2014.07.146

Peng A, Xiao X, Yue R (2014) Process parameter optimization for fused deposition modeling using response surface methodology combined with fuzzy inference system. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-014-5796-5

Zandi MD, Jerez-Mesa R, Lluma-Fuentes J et al (2020) Study of the manufacturing process effects of fused filament fabrication and injection molding on tensile properties of composite PLA-wood parts. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-020-05522-4

Wang S, Ma Y, Deng Z et al (2020) Effects of fused deposition modeling process parameters on tensile, dynamic mechanical properties of 3D printed polylactic acid materials. Polym Test. https://doi.org/10.1016/j.polymertesting.2020.106483

Hassanifard S, Hashemi SM (2020) On the strain-life fatigue parameters of additive manufactured plastic materials through fused filament fabrication process. Addit Manuf 32:100973. https://doi.org/10.1016/j.addma.2019.100973

Verbeeten WMH, Lorenzo-Bañuelos M, Arribas-Subiñas PJ (2020) Anisotropic rate-dependent mechanical behavior of Poly(Lactic Acid) processed by Material Extrusion Additive Manufacturing. Addit Manuf 31:100968. https://doi.org/10.1016/j.addma.2019.100968

Chen Y, Neff M, McEvoy B et al (2019) 3D printed polymers are less stable than injection moulded counterparts when exposed to terminal sterilization processes using novel vaporized hydrogen peroxide and electron beam processes. Polymer (Guildf). https://doi.org/10.1016/j.polymer.2019.121870

Zhang X, Chen L, Mulholland T, Osswald TA (2019) Characterization of mechanical properties and fracture mode of PLA and copper/PLA composite part manufactured by fused deposition modeling. SN Appl Sci. https://doi.org/10.1007/s42452-019-0639-5

Mohamed OA, Masood SH, Bhowmik JL (2017) Experimental investigation of time-dependent mechanical properties of PC-ABS prototypes processed by FDM additive manufacturing process. Mater Lett. https://doi.org/10.1016/j.matlet.2017.01.104

Zhao Y, Chen Y, Zhou Y (2019) Novel mechanical models of tensile strength and elastic property of FDM AM PLA materials: experimental and theoretical analyses. Mater Des. https://doi.org/10.1016/j.matdes.2019.108089

Beniak J, Holdy M, Križan P, Matúš M (2019) Research on parameters optimization for the additive manufacturing process. Transp Res Procedia 40:144–149. https://doi.org/10.1016/j.trpro.2019.07.024

Comminal R, Serdeczny MP, Pedersen DB, Spangenberg J (2019) Motion planning and numerical simulation of material deposition at corners in extrusion additive manufacturing. Addit Manuf. https://doi.org/10.1016/j.addma.2019.06.005

Pigeonneau F, Xu D, Vincent M, Agassant JF (2020) Heating and flow computations of an amorphous polymer in the liquefier of a material extrusion 3D printer. Addit Manuf. https://doi.org/10.1016/j.addma.2019.101001

Hebda M, McIlroy C, Whiteside B et al (2019) A method for predicting geometric characteristics of polymer deposition during fused-filament-fabrication. Addit Manuf. https://doi.org/10.1016/j.addma.2019.02.013

D’Amico A, Peterson AM (2018) An adaptable FEA simulation of material extrusion additive manufacturing heat transfer in 3D. Addit Manuf. https://doi.org/10.1016/j.addma.2018.02.021

Costa SF, Duarte FM, Covas JA (2017) Estimation of filament temperature and adhesion development in fused deposition techniques. J Mater Process Technol. https://doi.org/10.1016/j.jmatprotec.2017.02.026

Phan DD, Horner JS, Swain ZR et al (2020) Computational fluid dynamics simulation of the melting process in the fused filament fabrication additive manufacturing technique. Addit Manuf. https://doi.org/10.1016/j.addma.2020.101161

Serdeczny MP, Comminal R, Mollah MT et al (2020) Numerical modeling of the polymer flow through the hot-end in filament-based material extrusion additive manufacturing. Addit Manuf. https://doi.org/10.1016/j.addma.2020.101454

Comminal R, Serdeczny MP, Pedersen DB, Spangenberg J (2018) Numerical modeling of the strand deposition flow in extrusion-based additive manufacturing. Addit Manuf. https://doi.org/10.1016/j.addma.2017.12.013

Costa SF, Duarte FM, Covas JA (2015) Thermal conditions affecting heat transfer in FDM/FFE: a contribution towards the numerical modelling of the process. Virtual Phys Prototyp. https://doi.org/10.1080/17452759.2014.984042

D’Amico T, Peterson AM (2020) Bead parameterization of desktop and room-scale material extrusion additive manufacturing: how print speed and thermal properties affect heat transfer. Addit Manuf. https://doi.org/10.1016/j.addma.2020.101239

Lepoivre A, Boyard N, Levy A, Sobotka V (2020) Heat transfer and adhesion study for the FFF additive manufacturing process. In: Procedia Manufacturing. https://doi.org/10.1016/j.promfg.2020.04.291

Wang L, Chen X, Kang S et al (2020) Meta-modeling of high-fidelity FEA simulation for efficient product and process design in additive manufacturing. Addit Manuf. https://doi.org/10.1016/j.addma.2020.101211

Roy M, Wodo O (2020) Data-driven modeling of thermal history in additive manufacturing. Addit Manuf. https://doi.org/10.1016/j.addma.2019.101017

Zouaoui M, Labergere C, Gardan J, et al (2019) Numerical prediction of 3d printed specimens based on a strengthening method of fracture toughness. In: Procedia CIRP. https://doi.org/10.1016/j.promfg.2020.04.291

Soufivand AA, Abolfathi N, Hashemi SA, Lee SJ (2020) Prediction of mechanical behavior of 3D bioprinted tissue-engineered scaffolds using finite element method (FEM) analysis. Addit Manuf. https://doi.org/10.1016/j.addma.2020.101181

Fang L, Yan Y, Agarwal O et al (2020) Processing-structure-property relationships of bisphenol-A-polycarbonate samples prepared by fused filament fabrication. Addit Manuf. https://doi.org/10.1016/j.addma.2020.101285

Webbe Kerekes T, Lim H, Joe WY, Yun GJ (2019) Characterization of process–deformation/damage property relationship of fused deposition modeling (FDM) 3D-printed specimens. Addit Manuf 25:532–544. https://doi.org/10.1016/J.ADDMA.2018.11.008

Ghandriz R, Hart K, Li J (2020) Extended finite element method (XFEM) modeling of fracture in additively manufactured polymers. Addit Manuf. https://doi.org/10.1016/j.addma.2019.100945

Hasanov S, Gupta A, Nasirov A, Fidan I (2020) Mechanical characterization of functionally graded materials produced by the fused filament fabrication process. J Manuf Process. https://doi.org/10.1016/j.jmapro.2020.09.011

Tabacu S, Ducu C (2020) Numerical investigations of 3D printed structures under compressive loads using damage and fracture criterion: experiments, parameter identification, and validation. Extrem Mech Lett. https://doi.org/10.1016/j.eml.2020.100775

Costanzo A, Spotorno R, Candal MV et al (2020) Residual alignment and its effect on weld strength in material-extrusion 3D-printing of polylactic acid. Addit Manuf. https://doi.org/10.1016/j.addma.2020.101415

Brenken B, Barocio E, Favaloro A et al (2019) Development and validation of extrusion deposition additive manufacturing process simulations. Addit Manuf. https://doi.org/10.1016/j.addma.2018.10.041

Sunny SF, Gleason GH, Malik AS (2019) Comparison of numerical methods for fluid-structure interaction simulation of fused deposition modeled nylon components. In: Procedia Manufacturing. https://doi.org/10.1016/j.promfg.2019.06.215

Zhou Y, Lu H, Wang G et al (2020) Voxelization modelling based finite element simulation and process parameter optimization for Fused Filament Fabrication. Mater Des. https://doi.org/10.1016/j.matdes.2019.108409

El Moumen A, Tarfaoui M, Lafdi K (2019) Modelling of the temperature and residual stress fields during 3D printing of polymer composites. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-019-03965-y

Quelho de Macedo R, Ferreira RTL, Jayachandran K (2019) Determination of mechanical properties of FFF 3D printed material by assessing void volume fraction, cooling rate and residual thermal stresses. Rapid Prototyp J. https://doi.org/10.1108/RPJ-08-2018-0192

Cattenone A, Morganti S, Alaimo G, Auricchio F (2019) Finite element analysis of additive manufacturing based on fused deposition modeling: distortions prediction and comparison with experimental data. J Manuf Sci Eng Trans ASME. https://doi.org/10.1115/1.4041626

Courter B, Savane V, Bi J, et al (2017) Finite element simulation of the fused deposition modelling process. NAFEMS World Congr Stock Sweden, June. https://www.nafems.org/publications/resource_center/nwc17_469/

Stratasys Ltd. (2019) ABS Data Sheet. https://www.stratasys.com/materials/search/abs. Accessed 31 Oct 2019

Torrado AR, Roberson DA (2016) Failure analysis and anisotropy evaluation of 3D-printed tensile test specimens of different geometries and print raster patterns. J Fail Anal Prev. https://doi.org/10.1007/s11668-016-0067-4

Fernandez-Vicente M, Calle W, Ferrandiz S, Conejero A (2016) Effect of infill parameters on tensile mechanical behavior in desktop 3D printing. 3D Print Addit Manuf. https://doi.org/10.1089/3dp.2015.0036

Webbe Kerekes T, Lim H, Joe WY, Yun GJ (2019) Characterization of process–deformation/damage property relationship of fused deposition modeling (FDM) 3D-printed specimens. Addit Manuf. https://doi.org/10.1016/j.addma.2018.11.008

Samykano M, Selvamani SK, Kadirgama K et al (2019) Mechanical property of FDM printed ABS: influence of printing parameters. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-019-03313-0

Elmushyakhi A (2020) Freeze-thaw stabilization of fused deposition modeling 3D-printed SABIC structures. J King Saud Univ - Eng Sci. https://doi.org/10.1016/j.jksues.2020.09.002

Abeykoon C, Sri-Amphorn P, Fernando A (2020) Optimization of fused deposition modeling parameters for improved PLA and ABS 3D printed structures. Int J Light Mater Manuf. https://doi.org/10.1016/j.ijlmm.2020.03.003

Li H, Wang T, Li Q et al (2018) A quantitative investigation of distortion of polylactic acid/PLA) part in FDM from the point of interface residual stress. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-017-0820-1

Zhang W, Wu AS, Sun J et al (2017) Characterization of residual stress and deformation in additively manufactured ABS polymer and composite specimens. Compos Sci Technol. https://doi.org/10.1016/j.compscitech.2017.07.017

Acknowledgements

The author would like to thank Tecnologico de Monterrey Campus Toluca for providing a 3D printer and material for conducting the experimental trials. Thanks to MSC Software corporation for contributing with a trial license of Digimat and Marc Mentat software.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Camposeco-Negrete, C., Lavertu, PY. & Lopez-de-Alda, J. Prediction and optimization of the yield stress of material extrusion specimens made of ABS, using numerical simulation and experimental tests. Int J Adv Manuf Technol 118, 3657–3671 (2022). https://doi.org/10.1007/s00170-021-08180-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08180-2