Abstract

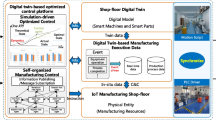

With the boosting development of the advanced manufacturing industry in the world, the original production pattern transformed from the traditional industries into the intelligence mode is completed with the least delay possible, which are still facing new challenges. The timeliness, stability, and reliability of them are significantly restricted due to the lack of real-time communication. Therefore, a model framework of intelligent workshop manufacturing system based on a digital twin is proposed in this paper, driving the deep information integration among the physical entity, data collection, and information decision-making. The traditional digital twin of conceptualization and fuzziness needs to be refined, optimized, and upgraded on the basis of the four-dimension collaborative model thinking. The model framework of a refined nine-layer intelligent digital twin is established. Firstly, the physical evaluation is refined into entity layer, auxiliary layer, and interface layer, scientific managing the physical resources and the instrument, and coordinating the overall system. Secondly, dividing the data evaluation into the data layer and the processing layer can greatly improve the flexible response-ability and ensure the synchronization of the real-time data. Finally, the system evaluation is subdivided into information layer, algorithm layer, scheduling layer, and functional layer, developing flexible manufacturing plan more reasonably, shortening the production cycle, and reducing logistics cost. Simultaneously, combining SLP and artificial bee colonies is applied to investigate the production system optimization of the textile workshop. The results indicate that the production efficiency of the optimized production system is increased by 34.46%.

Similar content being viewed by others

Data Availability

The data used to support the findings of this study is included within the article.

References

Hu C, Kong M, Pei J, Liu X, Pardalos PM (2021) Integrated inventory and production policy for manufacturing with perishable raw materials. Ann Math Artif Intel. https://doi.org/10.1007/s10472-021-09739-1

Bauer D, Bauernhansl T, Sauer A (2021) Improvement of delivery reliability by an intelligent control loop between supply network and manufacturing. Appl Sci 11(5):2205. https://doi.org/10.3390/app11052205

Yuan M, Li Y, Zhang L, Pei F (2021) Research on intelligent workshop resource scheduling method based on improved NSGA-II algorithm. Robot Cim-Int Manuf 71:102141. https://doi.org/10.1016/j.rcim.2021.102141

Wu R, Huang Z, Xie Y (2021) Layout optimization of workshop equipment based on witness. J Phys Conf Ser 1848(1):012017. https://doi.org/10.1088/1742-6596/1848/1/012017

Zhou B, Bao J, Li J, Lu Y, Liu T, Zhang Q (2021) A novel knowledge graph-based optimization approach for resource allocation in discrete manufacturing workshops. Robot Cim-Int Manuf 71:102160. https://doi.org/10.1016/j.rcim.2021.102160

Li H, Duan J, Zhang Q (2021) Multi-objective integrated scheduling optimization of semi-combined marine crankshaft structure production workshop for green manufacturing. T I Meas Control 43(3):579–596. https://doi.org/10.1177/0142331220945917

Han Y, Hu Y, Wang Y, Jia G, Ge C, Zhang C, Huang X (2020) Research and application of information model of a lithium ion battery intelligent manufacturing workshop based on OPC UA. Batteries 6(54):1–23. https://doi.org/10.3390/batteries6040052

Okumuş F, Dönmez E, Kocamaz AF (2020) A cloudware architecture for collaboration of multiple AGVs in indoor logistics: Case study in fabric manufacturing enterprises. Electronics 9(12):2023. https://doi.org/10.3390/electronics9122023

Shang X, Dong G (2019) Design and verification of a workshop environment monitoring system based on multiple communication modes. Acad J Eng T Sci 2(2):43–50. https://doi.org/10.25236/AJETS.020040

Jiang H, Qin S, Fu J, Zhang J, Ding G (2021) How to model and implement connections between physical and virtual models for digital twin application. J Manuf Syst 58:36–51. https://doi.org/10.1016/j.jmsy.2020.05.012

Li S, Liang Y, Bai S, Zhuang C, Cao Y (2021) Research on intelligent assembly modes of aerospace products based on digital twin. J Phy Conf Series 1756(1):012011. https://doi.org/10.1088/1742-6596/1756/1/012011

Liu ZF, Chen W, Zhang CX, Yang CB, Cheng Q (2020) Intelligent scheduling of a feature-process-machine tool supernetwork based on digital twin workshop. J Manuf Syst 58:157–167. https://doi.org/10.1016/j.jmsy.2020.07.016

Agnusdei GP, Elia V, Gnoni MG (2021) A classification proposal of digital twin applications in the safety domain. Comput Ind Eng 154(5):107137. https://doi.org/10.1016/j.cie.2021.107137

Fedorko G, Molnár V, Vasi M, Salai R (2021) Proposal of digital twin for testing and measuring of transport belts for pipe conveyors within the concept industry 4.0. Measurement 174:108978. https://doi.org/10.1016/j.measurement.2021.108978

Guo H, Zhu Y, Zhang Y, Ren Y, Chen M, Zhang R (2021) A digital twin-based layout optimization method for discrete manufacturing workshop. Int J Adv Manuf Tech 112(5):1307–1318. https://doi.org/10.1007/s00170-020-06568-0

Ma J, Chen H, Zhang Y, Guo H, Liu L (2020) A digital twin-driven production management system for production workshop. Int J Adv Manuf Tech 110(1–4):1385–1397. https://doi.org/10.1007/s00170-020-05977-5

Wang Y, Wu Z (2020) Model construction of planning and scheduling system based on digital twin. Int J Adv Manuf Tech 109(7):2189–2203. https://doi.org/10.1007/s00170-020-05779-9

Ritto TG, Rochinha FA (2021) Digital twin, physics-based model, and machine learning applied to damage detection in structures. Mech Syst Signal Pr 155:107614. https://doi.org/10.1016/j.ymssp.2021.107614

Zhao Z, Shen L, Yang C, Wu W, Huang GQ (2020) IoT and digital twin enabled smart tracking for safety management. Comput Oper Res 128(5):105183. https://doi.org/10.1016/j.cor.2020.105183

Li X, Cao J, Liu Z, Luo X (2020) Sustainable business model based on digital twin platform network: The inspiration from Haier’s case study in China. Sustainability 12(3):936. https://doi.org/10.3390/su12030936

Liu J, Gui H, Ma C (2021) Digital twin system of thermal error control for a large-size gear profile grinder enabled by gated recurrent unit. J Ambient Intel Humaniz Comput. https://doi.org/10.1007/s12652-021-03378-4

Wang X, Wang HF, Kong JS (2012) SLP-based layout design for a reclaimed rubber factory. Manuf Inf Eng China 628:111–116. https://doi.org/10.4028/www.scientific.net/AMR.628.111

Qi H, Zhou QH, Qian Z, Wang SZ, Fan W, Sun HF (2020) Layout optimization of dip dyeing workshop based on system layout planning-genetic algorithm. J Text Rese 41(03):84–90. https://doi.org/10.13475/j.fzxb.20190601907

Fahad M, Naqvi SAA, Atir M, Zubair M, Shehzad MM (2017) Energy management in a manufacturing industry through layout design. Procedia Manuf 8:168–174. https://doi.org/10.1016/j.promfg.2017.02.020

Chen W, Liu C, Huang X, Lai H, Li B (2016) SLP approach based facility layout optimization: an empirical study. Sci J Bus Manage 4(5):172–180. https://doi.org/10.11648/j.sjbm.20160405.15

Zhou X, Wu Y, Zhong M, Wang M (2021) Artificial bee colony algorithm based on multiple neighborhood topologies. Appl Soft Comput. https://doi.org/10.1016/j.asoc.2021.107697

Ogren, R. M., Kong, S. C. (2020). Optimization of diesel fuel injection strategies through applications of cooperative particle swarm optimization and artificial bee colony algorithms. Int J Engine Res, 1468087420954020https://doi.org/10.1177/1468087420954020

Li Y, Li X, Gao L, Zhang B, Pan QK, Tasgetiren MF, Meng L (2021) A discrete artificial bee colony algorithm for distributed hybrid flowshop scheduling problem with sequence-dependent setup times. Int J Engine Res 59(13):3880–3899. https://doi.org/10.1080/00207543.2020.1753897

Zha S, Guo Y, Huang S, Wang S (2020) A hybrid MCDM method using combination weight for the selection of facility layout in the manufacturing system: a case study. Math Probl Eng 45(3):1–16. https://doi.org/10.1155/2020/1320173

Liu Z, Chen W, Zhang C, Yang C, Cheng Q (2021) Intelligent scheduling of a feature-process-machine tool supernetwork based on digital twin workshop. J manuf syst 58:157–167. https://doi.org/10.1016/j.jmsy.2020.07.016

Qian W, Guo Y, Cui K, Wu P, Fang W, Liu D (2021) Multidimensional data modeling and model validation for digital twin workshop. J Comput Inf Sci Eng 21(3):031005. https://doi.org/10.1115/1.4049634

Lyu, J., Chen, P. S., Huang, W. T. (2020). Combining an automatic material handling system with lean production to improve outgoing quality assurance in a semiconductor foundry. Prod Plan Control, 829-844https://doi.org/10.1080/09537287.2020.1769217

Grieves M. (2011). Virtually perfect: driving innovative and lean products through product lifecycle management.

Zhuang C, Miao T, Liu J, Xiong H (2021) The connotation of digital twin, and the construction and application method of shop-floor digital twin. Robot Cim-Int Manuf 68:102075. https://doi.org/10.1016/j.rcim.2020.102075

Mathias SG, Schmied S, Grossmann D (2021) A framework for monitoring multiple databases in industries using OPC UA. J Amb Intel Hum Comp 12(1):47–56. https://doi.org/10.1007/s12652-020-02850-x

Arestova A, Martin M, Hielscher KSJ, German R (2021) A service-oriented real-time communication scheme for AUTOSAR adaptive using OPC UA and time-Sensitive networking. Sensors 21(7):2337. https://doi.org/10.3390/s21072337

Silva D, Carvalho LI, Soares J, Sofia RC (2021) A performance analysis of internet of things networking protocols: evaluating MQTT, CoAP. OPC UA Appl Sci 11(11):4879. https://doi.org/10.3390/app11114879

Muniraj SP, Xu X (2021) An implementation of OPC UA for machine-to-machine communications in a smart factory. Procedia Manuf 53:52–58. https://doi.org/10.1016/j.promfg.2021.06.009

Funding

Science and Technology Innovation Special Project of Rizhao of Shandong Province (No.2020CXZX1201).

Author information

Authors and Affiliations

Contributions

Zhongyu Zhang: Writing-original draft, methodology. Zhenjie Zhu: Writing-review and editing, formal analysis. Jingkun Wang: conceptualization, validation, supervision. Jinsheng Zhang: Investigation.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Consent for publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhang, Z., Zhu, Z., Zhang, J. et al. Construction of intelligent integrated model framework for the workshop manufacturing system via digital twin. Int J Adv Manuf Technol 118, 3119–3132 (2022). https://doi.org/10.1007/s00170-021-08171-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08171-3