Abstract

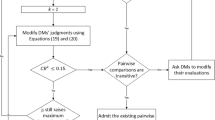

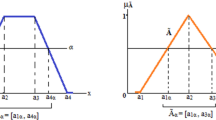

In the reliability optimization design field of CNC machine tools, reliability allocation plays a significant part, which has the characteristics of high complexity and strong uncertainty. Traditionally, reliability allocation methods have the disadvantages of a single allocation influence factor, too subjective or too objective, not flexible enough, etc. To solve the related problems, a novel reliability allocation method for machine tools is proposed, which combines subjective and objective weightings, and a variety of influencing factors are considered comprehensively. To deal with the characteristic of uncertainty and fuzziness in machine tool reliability analysis, different intuitionistic trapezoidal fuzzy numbers (ITrFNs) are allocated according to the importance of influencing factors. As the subjective method, the analytic hierarchy process (AHP) can reflect the decision maker’s subjective preferences of machine tool influence factors, while the grey relational method (GRA) can analyze the relationship between data which is adopted as an objective weighting method. The reliability of each subsystem is obtained by combining the two methods. Finally, the validity of the proposed method is proved by an illustration analyzing and comparing it with the traditional AHP method and fuzzy allocation methods.

Similar content being viewed by others

Data availability

The datasets used or analyzed during the current study are available from the corresponding author on reasonable request.

Code availability

Not applicable.

References

Cheng Q, Qi B, Liu Z et al (2019) An accuracy degradation analysis of ball screw mechanism considering time-varying motion and loading working conditions. Mech Mach Theory 134:1–23. https://doi.org/10.1007/s10845-016-1260-8

Wang X, Cui L, Wang H, Jiang H (2021) A generalized health indicator for performance degradation assessment of rolling element bearings based on graph spectrum reconstruction and spectrum racterization. Measurement 176(2021):109165. https://doi.org/10.1016/j.measurement.2021.109165

Wang S, He J, Li G et al (2021) Compilation method of CNC lathe cutting force spectrum based on kernel density estimation of G-SCE. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-021-07541-1

Jin T, Yan C, Chen C et al (2021) New domain adaptation method in shallow and deep layers of the CNN for bearing fault diagnosis under different working conditions. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-021-07385-9

Cui L, Sun Y, Wang X, Wang H (2021) Spectrum-based, full-band preprocessing, and two-dimensional separation of bearing and gear compound faults diagnosis. IEEE Trans Instrum Meas 70:3513216. https://doi.org/10.1109/TIM.2021.3063189

Yang Q, Li A (2015) Numerical control machine reliability allocation based on analytic hierarchy process and entropy weight coefficient method. Journal of Beijing Institute of Machinery 30(6):1–6

Zhang Z, Cai L, Cheng Q et al (2019) A geometric error budget method to improve machining accuracy reliability of multi-axis machine tools. J Intell Manuf 30:495–519. https://doi.org/10.1007/s10845-016-1260-8

Xiong J, Xue L, Yong L (2019) Research on CNC machine tools reliability modeling based on weighted least squares method. IOP Conf Ser: Mater Sci Eng 490(5). https://doi.org/10.1088/1757-899X/490/5/052003

Zhang Y, Jia J, Jing C, Huang X (2015) Reliability allocation of CNC machine tools based on failure information and fuzzy mathematics. Journal of Northeastern University 36(2):245–249. https://doi.org/10.3969/j.issn.1005-3026.2015.02.020

Du Y, Wu G, Xu L (2021) Reliability allocation method for remanufactured machine tools based on neural network and remanufacturing factor. Comput Integr Manuf Syst 27(4):1052–1061. https://doi.org/10.13196/j.cims.2021.04.009

Zhang G, Liu J, Wang G (2012) Fuzzy reliability allocation of CNC machine tools based on task. Comput Integr Manuf Syst 18(04):768–774

Xiao J, Chen Z, Lu Z (2006) Reliability fuzzy allocation of CNC machine tools. In: Proceedings of 2006 national mechanical reliability academic exchange conference. pp 54–59. (In Chinese)

Hou F (2012) Rank preserved aggregation rules and application to reliability allocation. Communications in Statistics-Theory and Methods 41(21):3831–3845. https://doi.org/10.1080/03610926.2012.688156

Kong D, Chang T, Pan J et al (2019) A decision variable-based combinatorial optimization approach for interval-valued intuitionistic fuzzy MAGDM. Inf Sci 484:197–218. https://doi.org/10.1016/j.ins.2019.01.016

Zhang Z, Cheng Q, Qi B, Tao Z (2021) A general approach for the machining quality evaluation of S-shaped specimen based on POS-SQP algorithm and Monte Carlo method. J Manuf Syst 60:553–568. https://doi.org/10.1016/j.jmsy.2021.07.020

Saaty TL (1978) A scaling method for priorities in hierarchical structures. J Math Psychol 1(1):57–68

Belforte G, Raparelli T, Viktorov V et al (2007) Discharge coefficients of orifice-type restrictor for aerostatic bearings. Tribol Int 40(3):512–521. https://doi.org/10.1016/j.triboint.2006.05.003

Hao Q, Yang Z, Chen C et al (2012) Reliability prediction for NC machine tool cased on interval AHP. Journal of Jilin University (Engineering and Technology Edition) 42(04):845–850

Tan R, Aviso K, Huelgas A, Promentilla M (2014) Fuzzy AHP approach to selection problems in process engineering involving quantitative and qualitative aspects. Process Saf Environ Prot 92(5):467–475. https://doi.org/10.1016/j.psep.2013.11.005

Wang C, Wang J (2014) Combining fuzzy AHP and fuzzy Kano to optimize product varieties for smart cameras: A zero-one integer programming perspective. Appl Soft Comput 22:410–416. https://doi.org/10.1016/j.asoc.2014.04.013

Zhang P, Liu Q, Kang B (2021) An improved OWA-Fuzzy AHP decision model for multi-attribute decision making problem. J Intell Fuzzy Syst 40(5):9655–9668. https://doi.org/10.3233/JIFS-202168

Cheng Q, Wang C, Sun D et al (2021) A new reliability allocation method for machine tools using the intuitionistic trapezoidal fuzzy numbers and TOPSIS. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-021-07331-9

Utkarsh SR, Bhatia V, Pattnaik PK (2021) Comparative Study of AHP and fuzzy AHP for ranking of medicinal drugs. Lect Notes Electr Eng 709:165–172. https://doi.org/10.1007/978-981-15-8752-8_17

Chang K (2017) A more general reliability allocation method using the hesitant fuzzy linguistic term set and minimal variance OWGA weights. Appl Soft Comput 56:589–596. https://doi.org/10.1016/j.asoc.2016.07.008

Wu W (2021) A revised grey relational analysis method for multicriteria group decision-making with expected utility theory for oil spill emergency management. Math Probl Eng 2021:2021. https://doi.org/10.1155/2021/6682332

Yang W, Wu Y (2019) A novel TOPSIS method based on improved grey relational analysis for multiattribute decision-making problem. Math Probl Eng 2019:2019. https://doi.org/10.1155/2019/8761681

Zhang P, Zhou W, Xie B, Song J (2010) A novel network selection mechanism in an integrated WLAN and UMTS environment using AHP and modified GRA. In: 2nd IEEE International Conference on Network Infrastructure and Digital Content. pp 104–109.https://doi.org/10.1109/ICNIDC.2010.5657905

Rani P, Mishra A, Ansari M et al (2021) Assessment of performance of telecom service providers using intuitionistic fuzzy grey relational analysis framework (IF-GRA). Soft Comput 25:1983–1993. https://doi.org/10.1007/s00500-020-05269-w

Nehi H, Maleki H (2005) Intuitionistic fuzzy numbers and it’s applications in fuzzy optimization problem. In: Proceedings of the 9th WSEAS International Conference on Systems. pp 1–5

Ye J (2011) Expected value method for intuitionistic trapezoidal fuzzy multicriteria decision-making problems. Expert Syst Appl 38(9):11730–11734. https://doi.org/10.1016/j.eswa.2011.03.059

Niu P, Cheng Q, Liu Z, Chu H (2021) A machining accuracy improvement approach for a horizontal machining center based on analysis of geometric error characteristics. Int J Adv Manuf Technol 112(9–10):2873–2887. https://doi.org/10.1007/s00170-020-06565-3

Zhang G, Zhang L (2014) Reliability prediction and allocation technology. Manufacturing Technology & Machine Tool 12:8–12

Du F, Zhang L, Du F (2021) Smart City Evaluation Index System: Based on AHP Method. Advances in Intelligent Systems and Computing 1303:563–569. https://doi.org/10.1007/978-981-33-4572-0_81

Deng J (2002) Grey theory basis. Huazhong University of Science and Technology Press

Uluçay V, Deli I, Şahin M (2019) Intuitionistic trapezoidal fuzzy multi-numbers and its application to multi-criteria decision-making problems. Complex & Intelligent Systems 5:65–78. https://doi.org/10.1007/s40747-018-0074-z

Funding

The National Natural Science Foundation of China (No. 51975012), the National Science and Technology Major Special Project (No. 2018ZX04033001), and the Beijing Nova Program Interdisciplinary Cooperation Project (No. Z191100001119010). Supported by Opening Project of the Key Laboratory of CNC Equipment Reliability, Ministry of Education, Jilin University (No. 202102).

Author information

Authors and Affiliations

Contributions

Qiang Cheng: methodology, validation, investigation, formal analysis, writing–review, and editing; Yongbo Kang: writing, methodology, and investigation; Congbin Yang: resources and overseeing of analysis; Caixia Zhang: supervision and review of the experimental setup; Chuanhai Chen: investigation.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

All authors voluntarily agree to participate in this research study.

Consent for publication

All authors voluntarily agree to the publication of the paper.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cheng, Q., Kang, Y., Yang, C. et al. A new reliability allocation method for machine tools based on ITrFNs and AHP-GRA. Int J Adv Manuf Technol 124, 4019–4032 (2023). https://doi.org/10.1007/s00170-021-08153-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08153-5