Abstract

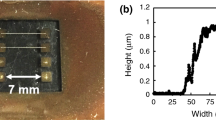

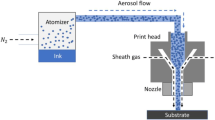

In this study, the ultraviolet (UV) radiation curing process and furnace curing process for curing aerosol jet printed nickel oxide (NiO) nanoparticle thin films were investigated. NiO has a negative temperature coefficient and can be used to fabricate temperature sensors. Four UV power settings (for 10 min) and four furnace temperatures (for 1 h) were used to cure the aerosol jet printed sensors. The resultant sensor resistance at 100 °C and 180 °C was measured, and the sensor’s sensitivity was characterized by a B value. Confocal microscopy was performed to characterize the sensor surface. The 60% UV power setting yields the lowest resistance and the highest B value among all sensors. The analysis of variations shows that the UV power setting is not a significant factor in the resistance and B value, while the furnace temperature is a significant factor. This indicates that UV curing is a more robust method and does not need to be optimized to achieve good results. The UV curing process not only reduces the required curing time but also improves the performance of the temperature sensor.

Similar content being viewed by others

Availability of data and material

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Code availability

Not applicable.

References

Liu H, Sun W, Xiang A, Shi T, Chen Q, Xu S (2012) Towards on-chip time-resolved thermal mapping with micro-/nanosensor arrays. Nanoscale Res Lett 7(1):484. https://doi.org/10.1186/1556-276X-7-484

Han IY, Kim SJ (2008) Diode temperature sensor array for measuring micro-scale surface temperatures with high resolution. Sens Actuators, A 141(1):52–58. https://doi.org/10.1016/j.sna.2007.07.020

Li K-M, Liang SY (2006) Modeling of cutting temperature in near dry machining. J Manuf Sci Eng 128(2):416–424. https://doi.org/10.1115/1.2162907

Ouyang P, Zhang H, Zhang Y, Wang J, Li Z (2015) Zr-substituted SnO2-based NTC thermistors with wide application temperature range and high property stability. J Mater Sci: Mater Electron 26(8):6163–6169. https://doi.org/10.1007/s10854-015-3197-7

Feteira A (2009) Negative temperature coefficient resistance (NTCR) ceramic thermistors: an industrial perspective. J Am Ceram Soc 92(5):967–983. https://doi.org/10.1111/j.1551-2916.2009.02990.x

Becker JA, Green CB, Pearson G (1946) Properties and uses of thermistors—thermally sensitive resistors. Electr Eng 65(11):711–725. https://doi.org/10.1109/EE.1946.6439939

Wood SD, Mangum BW, Filliben JJ, Tillett SB (1978) An investigation of the stability of thermistors. J Res Natl Bur Stan 83(3):247. https://doi.org/10.6028/jres.083.015

Wang CC, Akbar SA, Chen W, Schorr JR (1997) High-temperature thermistors based on yttria and calcium zirconate. Sens Actuators, A 58(3):237–243. https://doi.org/10.1016/S0924-4247(97)01394-0

Houivet D, Bernard J, Haussonne J-M (2004) High temperature NTC ceramic resistors (ambient–1000 °C). J Eur Ceram Soc 24(6):1237–1241. https://doi.org/10.1016/S0955-2219(03)00376-5

Wang C, Hong G-Y, Li K-M, Young H-T (2017) A miniaturized nickel oxide thermistor via aerosol jet technology. Sensors 17(11):2602. https://doi.org/10.3390/s17112602

Huang C-C, Kao Z-K, Liao Y-C (2013) Flexible miniaturized nickel oxide thermistor arrays via inkjet printing technology. ACS Appl Mater Interfaces 5(24):12954–12959. https://doi.org/10.1021/am404872j

Kamat RK, Naik GM (2002) Thermistors – in search of new applications, manufacturers cultivate advanced NTC techniques. Sens Rev 22(4):334–340. https://doi.org/10.1108/02602280210444654

Huang Q, Zhu Y (2019) Printing conductive nanomaterials for flexible and stretchable electronics: a review of materials, processes, and applications. Adv Mater Technol 4(5):1800546. https://doi.org/10.1002/admt.201800546

Mette A, Richter PL, Hörteis M, Glunz SW (2007) Metal aerosol jet printing for solar cell metallization. Prog Photovolt: Res Appl 15(7):621–627. https://doi.org/10.1002/pip.759

Salary R (Ross), Lombardi JP, Tootooni MS, Donovan R, Rao PK, Poliks MD (2016) In situ sensor-based monitoring and computational fluid dynamics (CFD) modeling of aerosol jet printing (AJP) process, in Volume 2: Materials; Biomanufacturing; Properties, Applications and Systems; Sustainable Manufacturing, Blacksburg, Virginia, USA. p. V002T04A049. https://doi.org/10.1115/MSEC2016-8535

Saleh E et al (2017) 3D inkjet printing of electronics using UV conversion. Adv Mater Technol 2(10):1700134. https://doi.org/10.1002/admt.201700134

Kelly KL, Coronado E, Zhao LL, Schatz GC (2003) The optical properties of metal nanoparticles: the influence of size, shape, and dielectric environment. J Phys Chem B 107(3):668–677. https://doi.org/10.1021/jp026731y

Zhang JZ, Noguez C (2008) Plasmonic optical properties and applications of metal nanostructures. Plasmonics 3(4):127–150. https://doi.org/10.1007/s11468-008-9066-y

Li Y, Verbiest T, Strobbe R, Vankelecom IFJ (2014) Silver nanoparticles as localized ‘nano-heaters’ under LED light irradiation to improve membrane performance. J Mater Chem A 2(9):3182. https://doi.org/10.1039/c3ta14406b

Govorov AO, Richardson HH (2007) Generating heat with metal nanoparticles. Nano Today 2(1):30–38. https://doi.org/10.1016/S1748-0132(07)70017-8

El-Kemary M, Nagy N, El-Mehasseb I (2013) Nickel oxide nanoparticles: synthesis and spectral studies of interactions with glucose. Mater Sci Semicond Process 16(6):1747–1752. https://doi.org/10.1016/j.mssp.2013.05.018

Polzinger B et al (2011) UV-sintering of inkjet-printed conductive silver tracks, in 2011 11th IEEE International Conference on Nanotechnology, Portland, OR, USA. pp. 201–204. https://doi.org/10.1109/NANO.2011.6144541

Wünscher S, Abbel R, Perelaer J, Schubert US (2014) Progress of alternative sintering approaches of inkjet-printed metal inks and their application for manufacturing of flexible electronic devices. J Mater Chem C 2(48):10232–10261. https://doi.org/10.1039/C4TC01820F

Montgomery DC (2017) Design and analysis of experiments. John Wiley & Sons, Hoboken

Funding

This work was supported in part by the National Science Foundation under Grant CMMI 1642565 (to Chen) and Ministry of Science and Technology in Taiwan under Overseas Project for Post Graduate Research 108–2917-I-002–025 (to Chang).

Author information

Authors and Affiliations

Contributions

Yi-Tse Chang: conception, analysis, execute experiments, writing—original draft preparation and editing, visualization—original draft preparation. Kuan-Yi Hung: conception and analysis, Hong-Tsu Young: writing—review and editing, supervision. Kuan-Ming Li: writing—review and editing, supervision. Roland K. Chen: visualization—review and editing, writing—review and editing, supervision.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chang, YT., Hung, KY., Young, HT. et al. Aerosol jet printing of nickel oxide nanoparticle ink with ultraviolet radiation curing for thin-film temperature sensors. Int J Adv Manuf Technol 118, 1957–1965 (2022). https://doi.org/10.1007/s00170-021-08046-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08046-7