Abstract

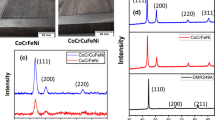

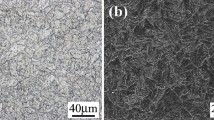

A synergistic combination of mechanical properties and corrosion resistance property is desired for most ocean engineering structural applications. In this paper, we prepared a high-entropy alloy (HEA) cladded layer of composition CrFeCoNiNb (atomic %). We aim to attain a balance between the mechanical property and the corrosion resistance property by adjusting the energy density. The prepared CrFeCoNiNb cladded layer with an energy density of 116.7 J/mm2 exhibited excellent mechanical properties and high corrosion resistance. The improved mechanical properties are attributed to fine grain strengthening, solid solution strengthening, and dispersion strengthening. Whereas, the excellent corrosion resistance is due to the formation of Laves corrosion-resistant phase structure and the compact passivation film. The variation of the mechanical properties and corrosion resistance with different energy densities are attributed to the phase composition. The proportion of the Laves phase decreases first and then increases with the increase of energy density, which is the main reason that the microhardness of the cladded layer follows a similar trend. The outcome of our research suggests that the prepared CrFeCoNiNb cladded layer could be explored to realize surface strengthening of load-bearing parts in marine engineering equipment.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Yeh JW (2013) Alloy design strategies and future trends in high-entropy alloys. Miner Met Mater Soc 65(12):1759–1711

Nene SS, Frank M, Liu K, Sinha S, Mishra RS (2020) Corrosion-resistant high entropy alloy with high strength and ductility. Scr Mater 166:168–172

Ding QQ, Zhang Y, Chen X, Fu X, Chen D, Chen S (2019) Tuning element distribution, structure and properties by composition in high-entropy alloys. Nature 574(7777):223–227

Dong Y, Yao Z, Huang X, Du F, Zhang Z (2020) Microstructure and mechanical properties of AlCoxCrFeNi3-x eutectic high-entropy alloy system. J Alloys Compd 823:1–6

Malty T, Prashanth KG, Janda A, Kim JT, Spieckermann F, Eckert J (2019) Mechanism of high-pressure torsion induced shear banding and lamellae thickness saturation in Co-Cr-Fe-Ni-Nb high entropy composites. J Mater Res 34(15):2672–2682

Xie T, Xiong Z, Xu Z, Liu Z, Cheng X (2021) Another eutectic point of Co–Cr–Fe–Ni-M (Hf, Ta, Nb) high-entropy system determined using a simple mixture method correlated with mixing enthalpy. Mater Sci Eng A 802:140634

Chaturvedi MC, Chung DW (1981) Yielding behavior of a γy-precipitation strengthened Co Ni Cr Nb Fe alloy. Metall Trans A 12(1):77–81

Tsau CH, Yeh CY, Tsai MC (2019) The effect of Nb-content on the microstructures and corrosion properties of CrFeCoNiNbx high-entropy alloys. Mater 12(22):3716

Zhang M, Zhang L, Liaw PK, Li G, Liu R (2018) Effect of Nb content on thermal stability, mechanical and corrosion behaviors of hypoeutectic CoCrFeNiNbx high-entropy alloys. J Mater Res 33(19):3276–3286

Wang W, Wu Q, Lu X, Xiao Y, Li J, Zhang Y (2019) Microstructure and corrosion behavior of (CoCrFeNi)95Nb5 high-entropy alloy coating fabricated by plasma spraying. Mater 12(5):1–12

Pud A, Ogurtsov N, Korzhenko A, Shapoval G (2003) Some aspects of preparation methods and properties of polyaniline blends and composites with organic polymers. Prog Polym Sci 28(12):1701–1753

Liu Y, Ding Y, Yang L, Sun R, Yang X (2021) Research and progress of laser cladded on engineering alloys: a review. J Manuf Process 66(1):341–363

Lt A, Af A, Lc B (2020) CoCr alloy processed by selective laser melting (SLM): effect of laser energy density on microstructure surface morphology and hardness. J Manuf Process 52:106–119

Biswas K, Yeh JW, Bhattacharjee PP, Hosson J (2020) High entropy alloys: key issues under passionate debate. Scr Mater 188:54–58

Cong N, Yan S, Jia L, Huang G (2018) Characterization of Al0.5FeCu0.7NiCoCr high-entropy alloy coating on aluminum alloy by laser cladded. Opt Laser Technol 105:257–263

Yeh JW, Chen SK, Lin SJ, Gan JY, Chin TS, Shun TT (2004) Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv Eng Mater 6(5):299–303

Zhang Y, Zhou YJ, Lin JP, Chen GL, Liaw PK (2008) Solid-solution phase formation rules for multi-component alloys. Adv Eng Mater 10(6):534–538

Cd A, Sgr BB (2017) Hume-rothery for HEA classification and self-organizing map for phases and properties prediction-ScienceDirect. J Alloys Compd 724:353–364

Juan YF, Li J, Jiang YQ, Jia WL, Lu ZJ (2019) Modified criterions for phase prediction in the multi-component laser-clad coatings and investigations into microstructural evolution/wear resistance of FeCrCoNiAlMox laser-clad coatings. Appl Surf Sci 465:700–714

Chung D, Ding Z, Yang Y (2019) Hierarchical eutectic structure enabling superior fracture toughness and superb strength in CoCrFeNiNb0.5 eutectic high entropy slloy at room temperature. Adv Eng Mater 21(3):1–11

Liu PC, Wang ZX, Cong JH, Zhang MR, Y Q, (2020) The significance of Nb interface segregation in governing pearlitic refinement in high carbon steels. Mater Lett 279:2–3

Ivanisenko Y, Sauvage X, Mazilkin A, Kilmametov A, Beach JA, Straumal BB (2018) Bulk nanocrystalline ferrite stabilized through grain boundary carbon segregation. Adv Eng Mater 20(10):1–6

Wang HH, Wang J, Tong Z, Hodgson PD, Wan XL, Wu KM (2018) Characterization of Nb interface segregation during welding thermal cycle in microalloyed steel by atom probe tomography. Metall Mater Trans A 49:2–5

Khodabakhshi F, Simchi A, Kokabi AH (2016) Surface modifications of an aluminum-magnesium alloy through reactive stir friction processing with titanium oxide nanoparticles for enhanced sliding wear resistance. Surf Coat Technol 309:114–123

Tao Lv, Huang Shuiquan Hu, Xiaodong, (2018) Tribological and machining characteristics of a minimum quantity lubrication (MQL) technology using GO/SiO2 hybrid nanoparticle water-based lubricants as cutting fluids. Int J Adv Manuf Technol 96(5–8):2931–2942

Li Y, Su K, Bai P, Wu L (2020) Microstructure and property characterization of Ti/TiBCN reinforced Ti based composite coatings fabricated by laser cladded with different scanning speed. Mater Charact 159:7–9

Archard JF (1953) Contact and rubbing of flat surfaces. J Appl Phys 24(8):981–989

Guo YX, Shang XJ, Liu QB (2018) Microstructure and properties of in-situ TiN reinforced laser cladded CoCr2FeNiTix high-entropy alloy composite coatings. Surf Coat Technol 344:353–358

Mazaheri Y, Jalilvand MM, Heidarpour A, Jahani AR (2019) Tribological behavior of AZ31/ZrO2 surface nanocomposites developed by friction stir processing. Tribol Int 143:106062

Taylor CD, Lu P, Saal J, Frankel GS, Scully JR (2018) Integrated computational materials engineering of corrosion resistant alloys. NPJ Mater Degrad 2(1):1–10

Funding

This work was supported by the Key Research and Development Program of Shandong Province (2019GNC106102) and the Natural Science Foundation of Shandong Province (ZR2019MEE059, ZR2018PEE011, ZR2019PEE041).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Song, P., Jiang, F., Wang, Y. et al. Effect of energy density on the microstructure and properties of the CrFeCoNiNb high-entropy cladded layer. Int J Adv Manuf Technol 118, 3949–3962 (2022). https://doi.org/10.1007/s00170-021-08042-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08042-x