Abstract

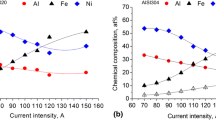

Alloying elements have been added to β-NiAl to improve strength and creep resistance at high temperature enhancing β-NiAl attractiveness and competitiveness. Particularly, tungsten carbides (WC) have been used to modify this aluminide, resulting in an increase in hardness and improved its tribological behavior in high temperature. However, the size of WC particles and the processing conditions account for the microstructure obtained and the resulting properties. This study takes an important step toward understanding how carbide particle size can contribute or interfere in the synthesis and microstructure of NiAl-based coatings. NiAl intermetallic coatings were processed by in situ synthesis during deposition by plasma transferred arc (PTA). Powder mixtures of elementary Ni and Al powders with and without the addition of 1 wt% carbide microparticles and of 1 wt% WC nanoparticles. Carbide microparticles increased the dilution with the substrate and consequently the density of point defects, which had a strong impact on hardness. However, the addition of WC nanoparticles had a negative impact on the synthesis of NiAl, delaying/inhibiting its formation, which was reflected on the microstructure and low hardness of coatings.

Similar content being viewed by others

Availability of data and material

Available upon request as this is parts.

Code availability

Not applicable.

References

Ozdemir O, Zeytin S, Bindal C (2010) Characterization of NiAl with cobalt produced by combustion synthesis. J Alloy Compd 508(1):216–221. https://doi.org/10.1016/j.jallcom.2010.08.056

Miracle DB, Darolia R (2000) NiAl and its Alloys. In: Westbrook JH, Fleischer RL (eds) Intermetallic compounds: structural applications of intermetallic compounds, vol 3. Wiley, Inglaterra, pp 55–74

Meetham GW, Van De Voorde MH (2000) Materials for high temperature engineering applications. Springer, Berlin

Yan K, Guo H, Gong S (2014) High-temperature oxidation behavior of β-NiAl with various reactive element dopants in dry and humid atmospheres. Corros Sci 83:335–342. https://doi.org/10.1016/j.corsci.2014.02.033

Noebe RD, Bowman RR, Nathal MV (1996) The physical and mechanical metallurgy of NiAl. In: Stoloff NS, Sikka VK (eds) Physical metallurgy and processing of intermetallic compounds. Chapman & Hall, New York, pp 212–296

Shokati AA, Parvin N, Sabzianpour N, Shokati M, Hemmati A (2013) In situ synthesis of NiAl–NbB2 composite powder through combustion synthesis. J Alloy Compd 549:141–146. https://doi.org/10.1016/j.jallcom.2012.08.024

Almeida VB, Takano EH, Mazzaro I, d’Oliveira ASCM (2011) Evaluation of Ni–Al coatings processed by plasma transferred arc. Surf Eng 27(4):266–271. https://doi.org/10.1179/026708410X12550773057866

Yuan J, Zhang X, Zhang C, Sun K, Liu C (2016) In-situ synthesis of NiAl/WC composites by thermal explosion reaction. Ceram Int 42(9):10992–10996. https://doi.org/10.1016/j.ceramint.2016.03.237

Miracle DB, Mendiratta MG (2000) Intermetallic composites. In: Westbrook JH, Fleischer RL (eds) Intermetallic compounds: structural applications of intermetallic compounds, vol 3. Wiley, Inglaterra, pp 293–307

Deuis RL, Yellup JM, Subramanian C (1998) Metal-matrix composite coatings by PTA surfacing. Compos Sci Technol 58(2):299–309. https://doi.org/10.1016/S0266-3538(97)00131-0

Brunetti C, Pintaude G, d’Oliveira ASCM (2014) The influence of Fe content on the mechanical properties of NiAl coatings processed in situ. J Mater Eng Perform 23(11):3934–3940. https://doi.org/10.1007/s11665-014-1203-5

He F (2013) Ceramic nanoparticles in metal matrix composites. In Ceramic nanocomposites. Woodhead Publishing, pp 185–207. https://doi.org/10.1533/9780857093493.2.185

Molina-Claros J, Hdz-García HM, Alvarez-Vera M, Pech-Canul MI, Muñoz-Arroyo R, García-Vázquez F, Díaz-Guillen JC (2017) Characterisation of PTA processed overlays without and with WC nanoparticles. Surf Eng 33(11):857–865. https://doi.org/10.1080/02670844.2017.1323442

D’Oliveira ASCM, Tigrinho JJ, Takeyama RR (2008) Coatings enrichment by carbide dissolution. Surf Coat Technol 202(19):4660–4665. https://doi.org/10.1016/j.surfcoat.2008.03.034

Yaedu AE, D’oliveira ASCM (2005) Cobalt based alloy PTA hardfacing on different substrate steels. Mater Sci Technol 21(4):459–466. https://doi.org/10.1179/174328413X13789824293380

Raynor GV, Rivlin VG (1988) Phase equilibria in iron ternary alloys: a critical assessment of the experimental literature. The Institute of Metals, 1 Carlton House Terrace, London

Milenkovic S, Schneider A, Frommeyer G (2011) Constitutional and microstructural investigation of the pseudobinary NiAl–W system. Intermetallics 19(3):342–349. https://doi.org/10.1016/j.intermet.2010.10.019

Alekseeva ZM (1993) Al-Ni-W (aluminium-nickel-tungsten). MSIT Ternary Evaluation Program, in MSIT Workplace

Nash P, Singleton MF, Murray JL (1992) Al-Ni phase diagram. In: ASM metals handbook. Alloy phase diagrams, vol 3, p 311

German RM, Iacocca RG (1996) Powder metallurgy processing. In: Stoloff NS, Sikka VK (eds) Physical metallurgy and processing of intermetallic compounds. Chapman & Hall, New York, pp 605–654

Benegra M, Pintaude G, D’Oliveira ASCM, Goldenstein H (2012) Characterization of NiCrAlC PTA coatings. Mater Res 15(5):775–778. https://doi.org/10.1590/S1516-14392012005000098

Dabiri AR, Mojallal RY, Ahmadi E, Fattahi M, Amirkhanlou S, Fattahi Y (2015) Effect of ZrO2 nanoparticles on the impact properties of shielded metal arc welds. Mater Lett 158:325–328. https://doi.org/10.1016/j.matlet.2015.05.159

Ramkumar KR, Natarajan S (2018) Investigations on microstructure and mechanical properties of TiO2 nanoparticles addition in Al 3003 alloy joints by gas tungsten arc welding. Mater Sci Eng A 727:51–60. https://doi.org/10.1016/j.msea.2018.04.111

Munroe PR, George M, Baker I, Kennedy FE (2002) Microstructure, mechanical properties and wear of Ni–Al–Fe alloys. Mater Sci Eng A 325(1–2):1–8. https://doi.org/10.1016/S0921-5093(01)01403-4

Cotton JD, Noebe RD, Kaufman MJ (1993) Ternary alloying effects in polycrystalline {beta}-NiAl (No. LA-UR-93–1395; CONF-930997–1). Los Alamos National Lab., NM (United States). https://www.osti.gov/servlets/purl/10157276

Pike LM, Chang YA, Liu CT (1997) Solid-solution hardening and softening by Fe additions to NiAl. Intermetallics 5(8):601–608. https://doi.org/10.1016/S0966-9795(97)00040-X

George EP, Liu CT (1990) Brittle fracture and grain boundary chemistry of microalloyed NiAl. J Mater Res 5(4):754–762. https://doi.org/10.1557/JMR.1990.0754

Acknowledgements

Important contributions were also gained from the use of equipment from the Electron Microscopy Center—CME/UFPR, X ray diffraction facilities, and Laboratory of Additive Manufacturing and Surface Engineering – LAMSE/UFPR.

Funding

This work was supported by Coodenação de aperfeiçoamento de pessoal de nível superior — CAPES and Funcação Arauçaria/PR for the schoolarship of Mr Abreu Castillo and CNPq — Conselho Nacional de Desenvolvimento científico e tecnológico (Grant # 3096608/2019–8).

Author information

Authors and Affiliations

Contributions

- H. O Abreu-Castillo — Methodology, Investigation, Data Curation, Writing—Original Draft, Writing—Review & Editing, Visualization.

- B. P. Bueno — Methodology, Investigation, Data Curation.

- Ana Sofia C. M. d’Oliveira — Conceptualization; Methodology, Investigation, Resources, Writing—Review & Editing, Supervision, Project administration, Funding acquisition.

Corresponding author

Ethics declarations

Ethics approval

This is an original work that has not been published or considered for publication elsewhere in any form or language.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abreu-Castillo, H.O., Bueno, B.P. & d’Oliveira, A.S.C.M. In situ processing aluminide coatings with and without tungsten carbide. Int J Adv Manuf Technol 119, 477–488 (2022). https://doi.org/10.1007/s00170-021-08032-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08032-z