Abstract:

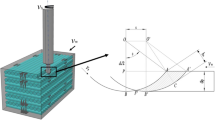

In view of the difficult machining characteristics of high volume fraction SiCp/Al composites, this paper researches the grinding force variation of grinding SiCp/Al composites with grinding rod. A diamond grinding rod with a diameter of 3mm is used to grind the SiCp/Al2024 composite with 60% volume fraction by the method of end face grinding. By measuring the tangential grinding forces and normal grinding forces after grinding, the theoretical model of unit grinding force is deduced. According to the experimental parameters of spindle speed, feed rate, and grinding depth, this paper derives the theoretical model of grinding force based on SiCp/Al2024 composites. And it clarifies the influence mechanism of grinding depth and feed rate on grinding force and explores the variation of grinding parameters on grinding force under dry grinding condition. Then the variation rule of grinding component force ratio is obtained. The related research and theoretical model have theoretical guiding significance for exploring the grinding properties of hard-to-machine materials.

Similar content being viewed by others

Abbreviations

- v s :

-

Spindle speed

- v w :

-

Feed rate

- a p :

-

Grinding depth

- F t :

-

Tangential grinding forces

- F n :

-

Normal grinding forces

- F p :

-

Unit grinding force

- F :

-

Grinding force

- C f :

-

Grinding component force ratio

References

Wang JF, Zhao JL, Chu KY (2018) Simulation study on cutting force of SiCp/A1 composite. Journal of System Simulation 30(4):1566–1571

Chen JP, Gu L, He GJ (2020) A review on conventional and nonconventional machining of SiC particle-reinforced aluminium matrix composites. Adv Manuf 8(3):279–315

Xiang DH, Shi ZL, Feng HR (2019) Finite element analysis of ultrasonic assisted milling of SiCp/Al composites. Int J Adv Manuf Technol 105(7-8):3477–3488

Xiang JF, Xie LJ, Gao FN (2018) Diamond tools wear in drilling of SiCp/Al matrix composites containing Copper. Ceram Int 44(5):5341–5351

Zhao X, Gong YD, Liang GQ (2021) Face grinding surface quality of high volume fraction SiCp/Al composite materials. Chinese Journal of Mechanical Engineering:34(1)

Zhou M, Zheng W. A model for grinding forces prediction in ultrasonic vibration assisted grinding of SiCp/Al composites. The International Journal of Advanced Manufacturing Technology, 2016

Sakthi S, Ramar M. Investigation of surface grinding characteristics of AL/SIC/AL2O3 composite using grey relational analysis. International Journal on Design & Manufacturing Technologies, 2016

Yin GQ, Wang D, Cheng J. Experimental investigation on micro-grinding of SiCp/Al metal matrix composites. The International Journal of Advanced Manufacturing Technology, 2019

Yu XL, Huang ST, Xu LF. ELID grinding characteristics of SiCp/Al composites. The International Journal of Advanced Manufacturing Technology, 2016

Huang ST, Yu XL. A study of grinding forces of SiCp/Al composites. The International Journal of Advanced Manufacturing Technology, 2018

Zhao L. Study on simulation and experiment of grinding force of SiCp/Al composite material. Shenyang Ligong University, 2012

Duan CZ, Che MF, Sun W, Yin WD (2019) Study of cutting force on high volume fraction SiCp/Al composites. Modular Machine Tool & Automatic Manufacturing Technique 02:1–4

Pramanik A, Zhang LC, Arsecularatne JA (2006) Prediction of cutting force in machining of metal matrix composites. Int J Mach Tools Manuf 46(14):1795–1803

Bian WL, Fu YC, Xu JH (2012) High-speed milling-force model for SiCp/Al composites. Aeronautical Manufacturing Technology 03:92–95

Han DR, Wang DZ, Liu HM (2001) Research on the cutting force properties of machining SiCp/2024 composites. Chinese High Technology Letters 07:94–96

Liu Q, Wang JF, Zhao JL, Chu KY, Liu SX (2018) Modeling of cutting forces in turning of SiCp/Al composites. Chinese Journal of Construction Machinery 16(03):211–215

Liu Y, Gong YD, Liu WJ, Sun XW (2020) Effect of milling parameters on chip shape and chip morphology for Zr-based bulk metallic glass by using micro-groove milling. Int J Adv Manuf Technol 111(5):1587–1602

Zhang FL, Li MC, Wang J (2020) Effect of arraying parameters on dry grinding performance of patterned monolayer brazed CBN wheel. Int J Adv Manuf Technol 107(5):2081–2089

Qu MN, Jin T, Xie GZ, Cai R, Yi J, Lu AG (2019) Thermal damage control for dry grinding of MgO/CeO2 glass ceramic. Int J Adv Manuf Technol 105:7–8

Younis MA, Alawi H (1984) Probabilistic analysis of the surface grinding process. Trans CSME 8(4):208–213

Gu P, Zhu CM, Tao Z, Yu YQ (2020) A grinding force prediction model for SiCp/Al composite based on single-abrasive-grain grinding. Int J Adv Manuf Technol 109:5–8

Zhang ZL, Cheng Q, Qi BB, Tao ZQ (2021) A general approach for the machining quality evaluation of S-shaped specimen based on POS-SQP algorithm and Monte Carlo method. J Manuf Syst 60:553–568

Duan CZ, Che MF, Sun W, Wei B, Liu YM (2019) Influence of different cooling and lubrication methods on tool wear in machining SiCp/Al composites. Acta Materiae Compositae Sinica 36(05):1244–1253

Cheng Q, Qi BB, Liu ZF, Xue DY (2019) An accuracy degradation analysis of ball screw mechanism considering time-varying motion and loading working conditions. Mech Mach Theory 134:1–23

Niu P, Cheng Q, Liu ZF, Chu HY (2021) A machining accuracy improvement approach for a horizontal machining center based on analysis of geometric error characteristics. Int J Adv Manuf Technol 112(9):2873–2887

Availability of data and material

The data used to support the findings of this study are available from the corresponding author upon request.

Funding

This work was supported by the National Natural Science Foundation of China (No.51905083, NO.51775100) and the Doctoral Start-up Fund of Liaoning Province (2019-BS-123).

Author information

Authors and Affiliations

Contributions

Guo did all the grinding experiments and wrote the papers. Gao guided Guo to revise the paper. Wang made a parameter measurement of the materials used in this experiment. Pan performed regular segmentation of the SiCp/Al composites. All authors read and approved the manuscript.

Corresponding author

Ethics declarations

Ethical approval

This research project has been approved by the Ethics Committee of Liaoning University of Technology.

Consent to participate

I solemnly declare that the paper “Study on removal mechanism and surface quality of high volume fraction SiCp/Al composites based on meso-scale” presented by us is the result of our research. This paper does not contain any work published or written by any other individual or group, except for the content specifically noted and cited in the paper. I fully realize that the legal consequences of this statement shall be borne by me.

Consent for publication

That the work described has not been published before;

that it is not under consideration for publication elsewhere;

that its publication has been approved by all coauthors, if any;

that its publication has been approved by the responsible authorities at the institution where the work is carried out.

The Author agrees to publication in the Journal indicated below and also to publication of the article in English by Springer in Springer’s corresponding English-language journal. The copyright to the English-language article is transferred to Springer effective if and when the article is accepted for publication. The author warrants that his/her contribution is original and that he/she has full power to make this grant. The author signs for and accepts responsibility for releasing this material on behalf of any and all coauthors. The copyright transfer covers the exclusive right to reproduce and distribute the article, including reprints, translations, photographic reproductions, microform, electronic form or any other reproductions of similar nature. After submission of the agreement signed by the corresponding author, changes of authorship or in the order of the authors listed will not be accepted by Springer. Journal: The International Journal of Advanced Manufacturing Technology, chemical samples Names of ALL contributing authors:Guangyan Guo, Qi Gao, Quanzhao Wang, and Shichao Pan.

Conflicts of interest

The authors declares no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Guo, G., Gao, Q., Wang, Q. et al. Study on grinding force of high volume fraction SiCp/Al2024 composites. Int J Adv Manuf Technol 124, 3813–3822 (2023). https://doi.org/10.1007/s00170-021-07881-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07881-y