Abstract

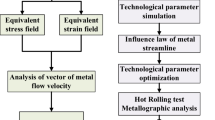

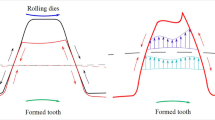

Cross rolling process with high-frequency induction heating is a new method to manufacture large-diameter gears, which has great advantage. While during the gear forming process, the defects of metal folding on the tooth top and asymmetrical flanks of tooth profiles occur, which severely affect the forming quality. To investigate the occurred defects, a simplified finite element (FE) model coupling electromagnetic-thermal and deformation fields is established in the DEFORM-3D software and is validated and considered reliable. Through numerical simulation and relevant experimental research, problems such as the metal folding on the tooth top and the asymmetrical flanks of the formed tooth profile in gear rolling process based on local induction heating are analyzed. The influence of the forming parameters on the defects is studied and can be concluded that the rabbit ear on the tooth top can be reduced by increasing the forming temperature and reducing the friction. Moreover, by the finish of alternating forward and reverse rotation, the profile error of left and right profile of workpiece decreased by 54%, proving the effectiveness of the finish process.

Similar content being viewed by others

Data availability

The datasets supporting the results of this article are included within the article.

References

Zhang D, Li Y, Fu J, Zheng Q (2009) Rolling force and rolling moment in spline cold rolling using slip-line field method. Chin J Mech Eng 22:688–695

Neugebauer R (2007) Improved process design and quality for gear manufacturing. CIRP Ann Manuf Technol 56:307–312

Neugebauer R, Hellfritzsch U, Lahl M (2008) Advanced process limits by rolling of helical gears. Int J of Mater Form 1:1183–1186

Neugebauer R, Klug D, Hellfritzsch U (2007) Description of the interactions during gear rolling as a basis for a method for the prognosis of the attainable quality parameters. Prod Eng Res Dev 1:253–257

Kamouneh A, Ni J, Stephenson D, Vriesen R, DeGrace G (2007) Diagnosis of involutometric issues in flat rolling of external helical gears through the use of finite-element models. Int J Mach Tool Manu 47:1257–1262

Kamouneh A, Ni J, Stephenson D, Vriesen R (2007) Investigation of work hardening of flat-rolled helical-involute gears through grain-flow analysis, FE-modeling, and strain signature. Int J Mach Tool Manu 47(7-8):1285–1291

Kamouneh A (2006) Feasibility of cold roll forming of external involute-helical gears for automatic transmission. Doctoral dissertation, University of Michigan

Yu J, Wang B, Hu Z (2011) Die design and experiment for forming the teeth of shafts by rolling. J Univ Sci Technol B 33(12):1544–1549

Li J, Wang G, Wu T (2017) Numerical-experimental investigation on the rabbit ear formation mechanism in gear rolling. Int J Adv Manuf Technol 91(9-12):3551–3559

Wu T, Wang G, Li J, Yan K (2018) Investigation on gear rolling process using conical gear rollers and design method of the conical gear roller. J Mater Process Technol 259:141–149

Ma Z, Luo Y, Wang Y, Mao J (2018) Geometric design of the rolling tool for gear roll-forming process with axial-infeed. J Mater Process Technol 258:67–79

Ma Z, Luo Y, Wang Y (2019) Numerical and experimental investigation on material flow in gear forced through feed rolling process. Int J Adv Manuf Technol 104:3361–3381

Zhang D, Zhao S (2014) New method for forming shaft having thread and spline by rolling with round dies. Int J Adv Manuf Technol 70:1455–1462

Ji H, Liu J, Wang B, Fu X, Xiao W, Hu Z (2017) A new method for manufacturing hollow valves via cross wedge rolling and forging: numerical analysis and experiment validation. J Mater Process Technol 240:1–11

Fu X, Wang B, Tang X, Ji H, Zhu X (2017) Study on induction heating of workpiece before gear rolling process with different coil structures. Appl Therm Eng 114:1–9

Fu X, Wang B, Zhu X, Tang X, Ji H (2017) Numerical and experimental investigations on large-diameter gear rolling. Int J Adv Manuf Technol 91:1–9

Lin Y, Chen X (2011) A critical review of experimental results and constitutive descriptions for metals and alloys in hot working. Mater Design 4:1733–1759

Lin J (2009) A pressure angle function method for describing tooth profiles of planar gears. J Mech Des 131:1–8

Funding

This study is supported by The National Key Research and Development Program of China (Grant No. 2018YFB1307900), the National Natural Science Foundation of China (Grant No. 51904206), Shanxi Province Science and Technology Major Projects (Grant Nos. 20181102015, 20201102003), and the Natural Science Foundation of Shanxi Province (Grant No. 201901D211011).

Author information

Authors and Affiliations

Contributions

Xiaobin Fu conducted the simulation and experiments. Baoyu Wang and Tao Wang provided experimental supports and innovative advices. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

The authors agree with the participation.

Consent for publication

All the authors have reached agreement for publication.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fu, X., Wang, B. & Wang, T. Experimental and numerical investigations on the deformation defects by gear rolling process with local induction heating. Int J Adv Manuf Technol 117, 835–844 (2021). https://doi.org/10.1007/s00170-021-07821-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07821-w