Abstract

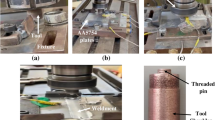

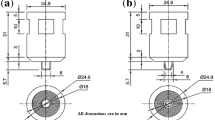

The welding process in aluminum is a complex process that commonly presents several issues such as weld bead discontinuity, cracks, and lack of penetration. Thus, an accurate specification of the parameters in order to achieve optimal values for the investigated responses is aimed by the industry. The present paper proposes the application of a multiobjective optimization approach considering multivariate constraints based on the simultaneous confidence intervals and the elliptical region of the correlated data. Structured experiments for the welding process of aluminum alloy (AA) 6063 TA tubes used in corona rings were performed according to a face-centered composite design with 4 factors, wire feed rate (Wf), arc voltage (V), contact tip to the workpiece distance (Ct), and motor frequency (Fr), resulting in 31 experiments. Poisson regression was applied to model the values of yield (Y), dilution (D), reinforcement index (RI), and penetration index (PI), allowing to estimate the optimal individual values with regard to the multivariate constraints. Rotated factor scores were obtained in order to replace the original data, and therefore, the factor multivariate square error was used as objective functions to be minimized through normal boundary intersection method. A satisfactory weld bead with large values of PI, D, and Y and a small value of RI was reached as prespecified by the manager of the process.

Similar content being viewed by others

Data Availability

All the data are available in the paper.

References

Murawwi EA, Mohammed A, Alip Z, Ei-Hag A (2013) Optimization of corona ring design for a 400KV non-ceramic insulator. 2013. IEEE Electr Insul Conf EIC 2013:370–373. https://doi.org/10.1109/EIC.2013.6554269

Abderrazzaq MH, Abu Jalgif AM (2013) Characterizing of corona rings applied to composite insulators. Electr Power Syst Res 95:121–127. https://doi.org/10.1016/j.epsr.2012.08.010

Farhad N, Asaad S, Pourya K (2020) Modeling and optimization of dimensions of corona rings on high-voltage composite insulators using FEM. Adv Sci Eng Med 12:1204–1207. https://doi.org/10.1166/asem.2020.2677

Rezaei A, Ehsanifar M, Wood DA (2019) Reducing welding repair requirements in refinery pressure vessel manufacturing: a case study applying six sigma principles. Int J Interact Des Manuf 13:1089–1102. https://doi.org/10.1007/s12008-019-00573-8

Meseguer-Valdenebro JL, Martinez-Conesa EJ, Serna J, Portoles A (2016) Influence of the welding parameters on the heat affected zone for aluminum welding. Therm Sci 20:643–653. https://doi.org/10.2298/TSCI140503106M

Braguine TB, de Alcântara DS, Castro CAC, dos Santos GHR (2018) Influência dos Parâmetros de Soldagem em Tubos de Alumínio AA6063 pelo Processo CDFW. Soldag Inspeção 23:3–16. https://doi.org/10.1590/0104-9224/si2301.02

Senthil SM, Parameshwaran R, Ragu Nathan S, Bhuvanesh Kumar M, Deepandurai K (2020) A multi-objective optimization of the friction stir welding process using RSM-based-desirability function approach for joining aluminum alloy 6063-T6 pipes. Struct Multidiscip Optim 62:1117–1133. https://doi.org/10.1007/s00158-020-02542-2

Liu B, Liu K, Villavicencio R, Dong A, Guedes Soares C (2021) Experimental and numerical analysis of the penetration of welded aluminium alloy panels. Ships Offshore Struct 16:492–504. https://doi.org/10.1080/17445302.2020.1736856

Ro C-S, Kim K-H, Bang H-S, Yoon H-S (2021) Joint properties of aluminum alloy and galvanized steel by AC Pulse MIG braze welding. Appl Sci 11:5105. https://doi.org/10.3390/app11115105

Hosseinabadi OF, Khedmati MR, Norouzipoor M (2021) Statistical analysis of initial deflection of aluminium plating between stiffeners. Thin-Walled Struct 161:107528. https://doi.org/10.1016/j.tws.2021.107528

Kang SG, Shin J (2021) The effect of laser beam intensity distribution on weld characteristics in laser welded aluminum alloy (AA5052). Opt Laser Technol 142:107239. https://doi.org/10.1016/j.optlastec.2021.107239

Cao X, Yi Z, Xu C, Luo Z, Duan J’ (2021) Study on laser/DP-MIG hybrid welding-brazing of aluminum to Al-Si coated boron steel. J Manuf Process 64:333–340. https://doi.org/10.1016/j.jmapro.2021.01.025

Miguel V, Marín-Ortiz F, Manjabacas MC, Martínez-Conesa EJ, Martínez-Martínez A, Coello J (2015) Optimización multiobjetivo del proceso de soldeo GMAW de la aleación AA 6063-T5 basado en la penetración y en la zona afectada térmicamente. Rev Metal 51:1–10. https://doi.org/10.3989/revmetalm.037

Martinez-Conesa EJ, Egea JA, Miguel V, Toledo C, Meseguer-Valdenebro JL (2017) Optimization of geometric parameters in a welded joint through response surface methodology. Constr Build Mater 154:105–114. https://doi.org/10.1016/j.conbuildmat.2017.07.163

Meseguer-Valdenebro JL, Portoles A, Matínez-Conesa E (2018) Electrical parameters optimisation on welding geometry in the 6063-T alloy using the Taguchi methods. Int J Adv Manuf Technol 98:2449–2460. https://doi.org/10.1007/s00170-018-2395-x

Duarte Costa DM, Brito TG, de Paiva AP, Leme RC, Balestrassi PP (2016) A normal boundary intersection with multivariate mean square error approach for dry end milling process optimization of the AISI 1045 steel. J Clean Prod 135:1658–1672. https://doi.org/10.1016/j.jclepro.2016.01.062

Koli Y, Yuvaraj N, Aravindan S, Vipin (2020) Multi-response mathematical modeling for prediction of weld bead geometry of AA6061-T6 using response surface methodology. Trans Indian Inst Metals 73:645–666. https://doi.org/10.1007/s12666-020-01883-2

Luz ER, Romão EL, Streitenberger SC, Gomes JHF, de Paiva AP, Balestrassi PP (2021) A new multiobjective optimization with elliptical constraints approach for nonlinear models implemented in a stainless steel cladding process. Int J Adv Manuf Technol 113:1469–1484. https://doi.org/10.1007/s00170-020-06581-3

De Motta RS, Afonso SMB, Lyra PRM (2012) A modified NBI and NC method for the solution of N-multiobjective optimization problems. Struct Multidiscip Optim 46:239–259. https://doi.org/10.1007/s00158-011-0729-5

Das I, Dennis JE (1998) Normal-boundary intersection: a new method for generating the pareto surface in nonlinear multicriteria optimization problems. SIAM J Optim 8:631–657. https://doi.org/10.1137/S1052623496307510

Mattiussi A, Rosano M, Simeoni P (2014) A decision support system for sustainable energy supply combining multi-objective and multi-attribute analysis: an Australian case study. Decis Support Syst 57:150–159. https://doi.org/10.1016/j.dss.2013.08.013

Costa DMD, Paula TI, Silva PAP, Paiva AP (2016) Normal boundary intersection method based on principal components and Taguchi’s signal-to-noise ratio applied to the multiobjective optimization of 12L14 free machining steel turning process. Int J Adv Manuf Technol 87:825–834. https://doi.org/10.1007/s00170-016-8478-7

De Freitas Gomes JH, Júnior ARS, De Paiva AP et al (2012) Global Criterion Method based on principal components to the optimization of manufacturing processes with multiple responses. Stroj Vestnik/Journal Mech Eng 58:345–353. https://doi.org/10.5545/sv-jme.2011.136

Oujebbour F, Habbal A, Ellaia R (2013) Optimization of concurrent criteria in the stamping process. In: Proceedings of 2013 International Conference on Industrial Engineering and Systems Management (IESM). pp 1–10

de Almeida FA, Santos ACO, de Paiva AP, Gomes GF, Gomes JHF (2020) Multivariate Taguchi loss function optimization based on principal components analysis and normal boundary intersection. Eng Comput. https://doi.org/10.1007/s00366-020-01122-8

Moura D, Barcelos V, Samanamud GRL, França AB, Lofrano R, Loures CCA, Naves LLR, Amaral MS, Naves FL (2018) Normal boundary intersection applied as multivariate and multiobjective optimization in the treatment of amoxicillin synthetic solution. Environ Monit Assess 190:190. https://doi.org/10.1007/s10661-018-6523-8

Naves FL, de Paula TI, Balestrassi PP, Moreira Braga WL, Sawhney RS, de Paiva AP (2017) Multivariate Normal Boundary Intersection based on rotated factor scores: a multiobjective optimization method for methyl orange treatment. J Clean Prod 143:413–439. https://doi.org/10.1016/j.jclepro.2016.12.092

Montgomery DC (2017) Design and Analysis of Experiments, 9th edn. John Wiley & Sons, New York

Singh D, Rao PV (2007) A surface roughness prediction model for hard turning process. Int J Adv Manuf Technol 32:1115–1124. https://doi.org/10.1007/s00170-006-0429-2

Moghaddas MA (2021) Modeling and optimization of thrust force, torque, and surface roughness in ultrasonic-assisted drilling using surface response methodology. Int J Adv Manuf Technol 112:2909–2923. https://doi.org/10.1007/s00170-020-06380-w

Ali MA, Ishfaq K, Jawad M (2019) Evaluation of surface quality and mechanical properties of squeeze casted AA2026 aluminum alloy using response surface methodology. Int J Adv Manuf Technol 103:4041–4054. https://doi.org/10.1007/s00170-019-03836-6

Natarajan U, Periyanan PR, Yang SH (2011) Multiple-response optimization for micro-endmilling process using response surface methodology. Int J Adv Manuf Technol 56:177–185. https://doi.org/10.1007/s00170-011-3156-2

Ribeiro R, Romão EL, Costa S et al (2020) Optimization of the resistance spot welding process of 22MnB5-galvannealed steel using response surface methodology and global criterion method based on principal components analysis. Metals (Basel) 10. https://doi.org/10.3390/met10101338

Saad MS, Nor AM, Baharudin ME, Zakaria MZ, Aiman AF (2019) Optimization of surface roughness in FDM 3D printer using response surface methodology, particle swarm optimization, and symbiotic organism search algorithms. Int J Adv Manuf Technol 105:5121–5137. https://doi.org/10.1007/s00170-019-04568-3

Myers RH, Montgomery DC, Anderson-Cook CM (2016) Response Surface Methodology Process and product optimization using designed experimetns. Fourth. John Wiley & Sons, Inc., Honoken, New Jersey

Agresti A (2015) Foundations Linear Generalized Linear Models

Meyers RH, Montgomery DC, Vining GG, Robinson TJ (2005) Generalized Linear Models with Applications ins Engineering and the Sciences, Second. John Wiley & Sons, Inc., Hoboken, New Jersey

De Paiva AP, Gomes JHF, Peruchi RS et al (2014) A multivariate robust parameter optimization approach based on Principal Component Analysis with combined arrays. Comput Ind Eng 74:186–198. https://doi.org/10.1016/j.cie.2014.05.018

Johnson RA, Wichern DW (2007) Applied multivariate statistical analysis. Sixth. Pearson Education, Inc., Upper Saddle River, New Jersey

Leite RR (2019) Método de interseção normal à fronteira para modelos quadráticos de escores fatoriais rotacionais. Federal University of Itajubá

Paiva AP, Paiva EJ, Ferreira JR, Balestrassi PP, Costa SC (2009) A multivariate mean square error optimization of AISI 52100 hardened steel turning. Int J Adv Manuf Technol 43:631–643. https://doi.org/10.1007/s00170-008-1745-5

Sakthivel P, Manobbala V, Manikandan T, Mohammed Arman Salik Z, Rajkamal G (2020) Investigation on mechanical properties of dissimilar metals using MIG welding. Mater Today Proc 37:531–536. https://doi.org/10.1016/j.matpr.2020.05.488

Meseguer-Valdenebro JL, Portoles A, Oñoro J (2016) Numerical study of TTP curves upon welding of 6063-T5 aluminium alloy and optimization of welding process parameters by Taguchi’s method. Indian J Eng Mater Sci 23:341–348

Paiva AP, Costa SC, Paiva EJ, Balestrassi PP, Ferreira JR (2010) Multi-objective optimization of pulsed gas metal arc welding process based on weighted principal component scores. Int J Adv Manuf Technol 50:113–125. https://doi.org/10.1007/s00170-009-2504-y

de Almeida FA, Streitenberger SC, Torres AF, de Paiva AP, Gomes JHDF (2020) A gage study through the weighting of latent variables under orthogonal rotation. IEEE Access 8:183557–183570. https://doi.org/10.1109/ACCESS.2020.3019031

Acknowledgements

The authors would like to thank the Brazilian agencies of CAPES, CNPq, and FAPEMIG for supporting this research.

Author information

Authors and Affiliations

Contributions

L.R.M., A.P.P., P.P.B., resources; A.P.P., E.R.L., S.C.S., E.L.R., P.P.B., investigation; E.R.L., E.L.R., S.C.S., data curation; S.C.S., E.L.R., E.R.L., writing—original draft preparation; E.L.R., S.C.S., E.R.L., L.R.M., writing—review and editing; A.P.P., E.R.L., S.C.S., E.L.R., P.P.B., visualization; A.P.P., P.P.B., supervision. All of the authors have read and agreed to publish this version of the manuscript.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Luz, E.R., Romão, E.L., Streitenberger, S.C. et al. A multiobjective optimization of the welding process in aluminum alloy (AA) 6063 T4 tubes used in corona rings through normal boundary intersection and multivariate techniques. Int J Adv Manuf Technol 117, 1517–1534 (2021). https://doi.org/10.1007/s00170-021-07761-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07761-5