Abstract

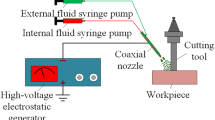

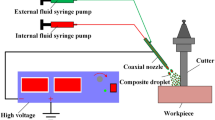

Composite electrostatic spraying (CES) is a process in which the coaxial jet generates when the inner and outer fluids flowing through the coaxial nozzle are charged, and jet end is broken into charged composite droplets. This paper experimentally investigated the effects of types of inner and outer fluids, voltages, and flow rates of inner and outer fluids on cutting force and cutting temperature in CES milling of aluminum alloy. The inner fluid used included water and multi-walled carbon nanotubes (MWCNTs)-water nanofluid. The outer fluid used involved castor oil, sunflower oil, MWCNTs-castor oil nanofluid, and MWCNTs-sunflower oil nanofluid. The atomization mode, current, and droplet velocity of CES were measured under different types of inner and outer fluids, voltages, and flow rates of inner and outer fluids. Results show that from the viewpoint of reducing cutting force and temperature, MWCNTs-sunflower oil nanofluid/MWCNTs-water nanofluid and 5 ml/h were the optimal outer/inner fluid combination and flow rate due to excellent charging performance, high droplet velocity, and superior friction-reducing effects of sunflower oil and MWCNTs.

Similar content being viewed by others

Data availability

Not applicable

Code availability

Not applicable

References

Wang XM, Li CH, Zhang YB, Ding WF, Yang M, Gao T (2020) Vegetable oil-based nanofluid minimum quantity lubrication turning: academic review and perspectives. Journal of Manufacturing Processes 59:76–97

Su Y (2016) Investigation into the role of cooling/lubrication effect of cryogenic minimum quantity lubrication in machining of AISI H13 steel by three-dimensional finite element method. Proceeding of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture 230(6):1003–1016

Su Y, Gong L, Li B, Liu ZQ, Chen DD (2016) Performance evaluation of nanofluid MQL with vegetable-based oil and ester oil as base fluids in turning. International Journal of Advanced Manufacturing Technology 83:2083–2089

Cai CY, Liang X, An QL, Tao ZR, Ming WW, Chen M (2021) Cooling/lubrication performance of dry and supercritical CO2-based minimum quantity lubrication in peripheral milling Ti-6Al-4V. International Journal of Precision Engineering and Manufacturing-Green Technology 8:405–421

Lv T, Huang SQ, Liu ET, Ma YL, Xu XF (2018) Tribological and machining characteristics of an electrostatic minimum quantity lubrication (EMQL) technology using graphene nano-lubricants as cutting fluids. Journal of Manufacturing Processes 34:225–237

Zhang MJ, Tan Y, Zhou FJ, Mao C, Xie ZZ, Li CH (2017) Analysis of flow field in cutting zone for spiral orderly distributed fiber tool. International Journal of Advanced Manufacturing Technology 92:4345–4354

Mao C, Lu J, Zhao ZH, Yin LR, Hu YL, Bi ZM (2018) Simulation and experiment of cutting characteristics for single cBN-WC-10Co fiber. Precision Engineering 52:170–182

Dang JQ, Zhang H, An QL, Ming WW, Chen M (2021) Surface modification of ultrahigh strength 300M steel under supercritical carbon dioxide (scCO2)-assisted grinding process. Journal of Manufacturing Processes 61:1–14

Varghese V, Akhil K, Ramesh MR, Chakradhar D (2019) Investigation on the performance of AlCrN and AlTiN coated cemented carbide inserts during end milling of maraging steel under dry, wet and cryogenic environments. Journal of Manufacturing Processes 43:136–144

Wang FB, Wang YQ (2018) Investigate on milling force of cryogenic cooling processing aluminum honeycomb treated by ice fixation. International Journal of Advanced Manufacturing Technology 98:1253–1265

Reddy NSK, Nouari M, Yang M (2010) Development of electrostatic solid lubricant system for improvement in machining process performance. International Journal of Machine Tools and Manufacture 50(9):789–797

Reddy NSK, Yang M (2010) Development of an electro static lubrication system for drilling of SCM 440 steel. Proceeding of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture 224(2):217–224

Su Y, Lu Q, Yu T, Liu ZQ, Zhang CY (2019) Machining and environmental effects of electrostatic atomization lubrication in milling operation. International Journal of Advanced Manufacturing Technology 104:2773–2782

Su Y, Jiang H, Liu ZQ (2021) An experimental investigation on heat transfer performance of electrostatic spraying used in machining. International Journal of Advanced Manufacturing Technology 112:1285–1294

Su Y, Jiang H, Liu ZQ (2020) A study on environment-friendly machining of titanium alloy via composite electrostatic spraying. International Journal of Advanced Manufacturing Technology 110:1305–1317

Debnath S, Reddy MM, Yi QS (2014) Environmental friendly cutting fluids and cooling techniques in machining: a review. Journal of Cleaner Production 83:33–47

Li XL, He N, Li L (2005) MQL technology in green cutting. Aviation Precision Manufacturing Technology 41(2):24–35

Su Y, Tang ZC, Wan RR (2017) An investigation on the electrostatic atomization mode of nanofluid using cutting tool as electrode. Advances in Mechanical Engineering 9(11):1–12

Jaworek A, Sobczyk AT (2008) Electrospraying route to nanotechnology: an overview. Journal of Electrostatics 66(3-4):197–219

López-Herrera JM, Barrero A, López A, Loscertales IG, Márquez M (2003) Coaxial jets generated from electrified Taylor cones. Scaling laws. Journal of Aerosol Science 34:535–552

Loscertales IG, Barrero A, Guerrero I, Cortijo R, Márquez M, Ganán-calvo AM (2002) Micro/nano encapsulation via electrified coaxial liquid jets. Science 295(5560):1695–1698

Su Y, Tang ZC, Wang GC, Wan RR (2018) Influence of carbon nanotube on the tribological properties of vegetable-based oil. Advances in Mechanical Engineering 10(5):1–11

Yin QA (2018) Tribological performance and experimental study of the tool/workpiece interface in nanofluids MQL end-milling. Master thesis, Qingdao University of Technology, China.

Funding

This work was supported by the National Natural Science Foundation of China (grant number 51205177), the Natural Science Foundation of Jiangsu Province (grant numbers BK2012277 and BK20171307), and the Natural Science Program for Basic Research of Jiangsu Province (grant number 08KJB460002).

Author information

Authors and Affiliations

Contributions

Yu Su: Project administration, resources, funding acquisition, supervision, reviewing and editing, and validation. Xiaorong Hu: Investigation and writing (original draft). Dongdong Zhang: Investigation and reviewing and editing. Hai Jiang: Analysis and reviewing and editing. Zhiqiang Liu: Analysis and reviewing and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Su, Y., Hu, X., Zhang, D. et al. Performance evaluation of composite electrostatic spraying (CES) in milling process. Int J Adv Manuf Technol 117, 109–123 (2021). https://doi.org/10.1007/s00170-021-07737-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07737-5