Abstract

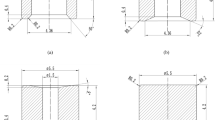

For the sake of improving the static mechanical properties and decreasing the exterior protrusion height of the clinched joint, a mechanical rivet-reinforcing process with different reinforcing loads was carried out to join AA5052 sheets in this study. Tubular rivets with 1 mm wall thickness were used to conduct the rivet-reinforcing experiment. The static strength, failure mode, neck thickness, interlock value and energy absorption of the rivet-reinforced joints realized with different reinforcing loads were comprehensively analyzed by experimental method. With the gradual increase of the reinforcing load, the interlock value and neck thickness were enlarged, while the height of exterior protrusion was decreased. When the reinforcing load was 45 kN, the height of exterior protrusion was decreased from 1.17 to 0.52 mm. The energy absorption and average static strength of dissimilar rivet-reinforced joints were significantly higher than that of the conventional clinched joints. The average strength was increased from 1835.23 to 4032.87 N in the single-lap-shear test, and from 1395.02 to 1658.99 N in the cross-lap-tensile test. The energy absorption of joint was increased from 1.34 to 6.77 J in the single-lap-shear test, and from 4.26 to 9.18 J in the cross-lap-tensile test. It was proved that rivet-reinforcing process with tubular rivet can effectively increase the mechanical properties of the conventional clinched joints.

Similar content being viewed by others

References

Xu F, Zhao SD, Han XL (2014) Use of a modified Gurson model for the failure behaviour of the clinched joint on Al6061 sheet. Fatigue Fract Eng Mater Struct 37(3):335–348. https://doi.org/10.1111/ffe.12118

Dean A, Rolfes R, Grbic N, Hübner S, Behrens B (2019) A FEM-based virtual test-rig for hybrid metal-composites clinching joints. Mater Werkst 50(8):973–986. https://doi.org/10.1002/mawe.201800198

He XC (2017) Clinching for sheet materials. Sci Technol Adv Mater 18(1):381–405. https://doi.org/10.1080/14686996.2017.1320930

Kaščák Ľ, Spišák E, Majerníková J (2016) Joining three car body steel sheets by clinching method. Open Eng 6(1):556–573

Xing BY, He XC, Wang YQ, Yang HY, Deng CJ (2015) Study of mechanical properties for copper alloy H62 sheets joined by self-piercing riveting and clinching. J Mater Process Technol 216:28–36. https://doi.org/10.1016/j.jmatprotec.2014.08.030

Atia MKS, Jain MK (2020) A novel approach to hot die-less clinching process for high strength AA7075-T6 sheets. Proc Inst Mech Eng C J Mech Eng Sci 234(19):3809–3825. https://doi.org/10.1177/0954406220917406

Sabra Atia MK, Jain MK (2018) A parametric study of FE modeling of die-less clinching of AA7075 aluminum sheets. Thin-Walled Struct 132:717–728. https://doi.org/10.1016/j.tws.2018.09.001

Gerstmann T, Awiszus B (2014) Recent developments in flat-clinching. Comput Mater Sci 81:39–44. https://doi.org/10.1016/j.commatsci.2013.07.013

Ren XQ, Chen C, Ran XK, Gao XL, Gao Y (2021) Investigation on lightweight performance of tubular rivet-reinforced joints for joining AA5052 sheets. J Braz Soc Mech Sci Eng 43(7). https://doi.org/10.1007/s40430-021-03053-x

Chen C, Fan SQ, Han XL, Zhao SD, Cui MC, Ishida T (2017) Experimental study on the height-reduced joints to increase the cross-tensile strength. Int J Adv Manuf Technol 91(5-8):2655–2662. https://doi.org/10.1007/s00170-016-9939-8

Chen C, Han XL, Zhao SD, Xu F, Zhao XZ, Ishida T (2017) Comparative study on two compressing methods of clinched joints with dissimilar aluminum alloy sheets. Int J Adv Manuf Technol 93(5-8):1929–1937. https://doi.org/10.1007/s00170-017-0650-1

Chen C, Li YX, Zhai ZY, Zhao SD, Zhang P, Huang MH, Li YB (2019) Comparative investigation of three different reforming processes for clinched joint to increase joining strength. J Manuf Process 45:83–91. https://doi.org/10.1016/j.jmapro.2019.06.009

Busse S, Merklein M, Roll K, Ruther M, Zurn M (2010) Development of a mechanical joining process for automotive body-in-white production. Int J Mater Form 3:1059–1062. https://doi.org/10.1007/s12289-010-0953-3

Chen C, Zhao SD, Cui MC, Han XL, Fan SQ (2016) Mechanical properties of the two-steps clinched joint with a clinch-rivet. J Mater Process Technol 237:361–370. https://doi.org/10.1016/j.jmatprotec.2016.06.024

Chen C, Zhao SD, Han XL, Cui MC, Zhao XZ, Ishida T (2017) Experimental investigation of the mechanical reshaping process for joining aluminum alloy sheets with different thicknesses. J Manuf Process 26:105–112. https://doi.org/10.1016/j.jmapro.2017.01.015

Kaðèák L, Spiðák E, Kubík R, Mucha J (2017) Finite element calculation of clinching with rigid die of three steel sheets. Strength Mater 49(4):488–499

Peng H, Chen C, Zhang HY, Ran XK (2020) Recent development of improved clinching process. Int J Adv Manuf Technol 110(11-12):3169–3199. https://doi.org/10.1007/s00170-020-05978-4

Lambiase F (2015) Joinability of different thermoplastic polymers with aluminium AA6082 sheets by mechanical clinching. Int J Adv Manuf Technol 80(9-12):1995–2006. https://doi.org/10.1007/s00170-015-7192-1

Chu MM, He XC, Zhang J, Lei L (2018) Clinching of similar and dissimilar sheet materials of galvanized steel, aluminium alloy and titanium alloy. Mater Trans 59(4):694–697. https://doi.org/10.2320/matertrans.M2017319

Dean A, Rolfes R, Behrens BA, Hübner S, Chugreev A, Grbic N (2018) Parametric study of hybrid metal-composites clinching joints. Key Eng Mater 767:413–420. https://doi.org/10.4028/www.scientific.net/KEM.767.413

Abe Y, Kato T, Mori K, Nishino S (2014) Mechanical clinching of ultra-high strength steel sheets and strength of joints. J Mater Process Technol 214(10):2112–2118. https://doi.org/10.1016/j.jmatprotec.2014.03.003

Abe Y, Saito T, Mori KI, Kato T (2018) Mechanical clinching with dies for control of metal flow of ultra-high-strength steel and high-strength steel sheets. Proceedings of the Institution of Mechanical Engineers Part B-Journal of Engineering Manufacture 232 (4):644-649. doi:https://doi.org/10.1177/0954405416683429

He XC, Zhang Y, Xing BY, Gu FS, Ball A (2015) Mechanical properties of extensible die clinched joints in titanium sheet materials. Mater Design 71:26–35. https://doi.org/10.1016/j.matdes.2015.01.005

Han XL, Zhao SD, Chen C, Liu C, Xu F (2017) Optimization of geometrical design of clinching tools in flat-clinching. Proceedings of the Institution of Mechanical Engineers Part C-Journal of Mechanical Engineering Science 231 (21):4012-4021. doi:https://doi.org/10.1177/0954406216660335

Han XL, Zhao SD, Liu C, Chen C, Xu F (2016) Optimization of geometrical design of clinching tools in clinching process with extensible dies. Proc Inst Mech Eng C J Mech Eng Sci 231(21):3889–3897. https://doi.org/10.1177/0954406216660336

He XC, Liu FL, Xing BY, Yang HY, Wang YQ, Gu FS, Ball A (2014) Numerical and experimental investigations of extensible die clinching. Int J Adv Manuf Technol 74(9-12):1229–1236. https://doi.org/10.1007/s00170-014-6078-y

He XC (2009) Recent development in finite element analysis of clinched joints. Int J Adv Manuf Technol 48(5-8):607–612. https://doi.org/10.1007/s00170-009-2306-2

Lambiase F, Di Ilio A (2012) Finite element analysis of material flow in mechanical clinching with extensible dies. J Mater Eng Perform 22(6):1629–1636. https://doi.org/10.1007/s11665-012-0451-5

Lambiase F, Di Ilio A (2013) Optimization of the clinching tools by means of integrated FE modeling and artificial intelligence techniques. In: Teti R (ed) Eighth Cirp Conference on Intelligent Computation in Manufacturing Engineering. Procedia CIRP. Elsevier, Amsterdam, pp 163–168. https://doi.org/10.1016/j.procir.2013.09.029

Chen C, Zhang HY, Xu YQ, Wu JL (2020) Investigation of the flat-clinching process for joining three-layer sheets on thin-walled structures. Thin-Walled Struct:157. https://doi.org/10.1016/j.tws.2020.107034

Neugebauer R, Mauermann R, Dietrich S, Kraus CJPE (2007) A new technology for the joining by forming of magnesium alloys. 1 (1):65-70

Chen C, Li YX, Zhang HY, Li YB, Pan Q, Han XL (2020) Investigation of a renovating process for failure clinched joint to join thin-walled structures. Thin-Walled Struct:151. https://doi.org/10.1016/j.tws.2020.106686

Chen C, Ran X, Pan Q, Zhang H, Yi R, Han X (2020) Research on the mechanical properties of repaired clinched joints with different forces. Thin-Walled Struct:152. https://doi.org/10.1016/j.tws.2020.106752

Chen C, Zhang HY, Peng H, Ran XK, Pan Q (2020) Investigation of the restored joint for aluminum alloy. Metals 10(1):1–13. https://doi.org/10.3390/met10010097

Shi C, Yi RX, Chen C, Peng H, Ran XK, Zhao SD (2020) Forming mechanism of the repairing process on clinched joint. J Manuf Process 50:329–335. https://doi.org/10.1016/j.jmapro.2019.12.025

Lei L, He XC, Yu TX, Xing BY (2019) Failure modes of mechanical clinching in metal sheet materials. Thin-Walled Struct 144:106281. https://doi.org/10.1016/j.tws.2019.106281

Chen C, Zhao SD, Han XL, Cui MC, Fan SQ (2016) Optimization of a reshaping rivet to reduce the protrusion height and increase the strength of clinched joints. J Mater Process Technol 234:1–9. https://doi.org/10.1016/j.jmatprotec.2016.03.006

Chen C, Zhao SD, Han XL, Cui MC, Fan SQ (2016) Investigation of mechanical behavior of the reshaped joints realized with different reshaping forces. Thin-Walled Struct 107:266–273. https://doi.org/10.1016/j.tws.2016.06.020

He XC, Zhao L, Yang HY, Xing BY, Wang YQ, Deng CJ, Gu FS, Ball A (2014) Investigations of strength and energy absorption of clinched joints. Comput Mater Sci 94:58–65. https://doi.org/10.1016/j.commatsci.2014.01.056

Schwarz C, Kropp T, Kraus C, Drossel WG (2020) Optimization of thick sheet clinching tools using principal component analysis. Int J Adv Manuf Technol 106(1-2):471–479. https://doi.org/10.1007/s00170-019-04512-5

Mucha J (2011) The analysis of lock forming mechanism in the clinching joint. Mater Design 32(10):4943–4954. https://doi.org/10.1016/j.matdes.2011.05.045

Availability of data and materials

The raw/processed data required to reproduce these findings cannot be shared at this time due to technical or time limitations

Code availability

Not applicable.

Funding

This research work is supported by the National Natural Science Foundation of China (Grant No. 51805416), Young Elite Scientists Sponsorship Program by CAST, Natural Science Foundation of Hunan Province (Grant No. 2020JJ5716), the Project of State Key Laboratory of High Performance Complex Manufacturing, Central South University (Grant No. ZZYJKT2019-01), Huxiang High-Level Talent Gathering Project of HUNAN Province (Grant No. 2019RS1002), and Hunan Provincial Natural Science Foundation for Excellent Young Scholars.

Author information

Authors and Affiliations

Contributions

Chao Chen and Xiaoqiang Ren conceived and designed the experiments; Chao Chen and Xiaoqiang Ren performed the experiments; Yawen Ouyang, Denglin Qin, and Jinliang Wu analyzed the data; Chao Chen, Jinliang Wu and Denglin Qin contributed reagents/materials/analysis tools; Chao Chen and Xiaoqiang Ren wrote the paper.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent to publish

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ren, X., Chen, C., Qin, D. et al. Mechanical properties of tubular rivet-reinforced joints realized with different reinforcing loads. Int J Adv Manuf Technol 117, 877–888 (2021). https://doi.org/10.1007/s00170-021-07734-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07734-8